Solid chemical dust suppression agent and preparation method thereof

A dust suppressant and chemical technology, applied in the field of environmental pollution control, can solve the problems of unpredictable effects, unseen, single function of the dust suppressant, etc., and achieve the effect of preventing dust from flying and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

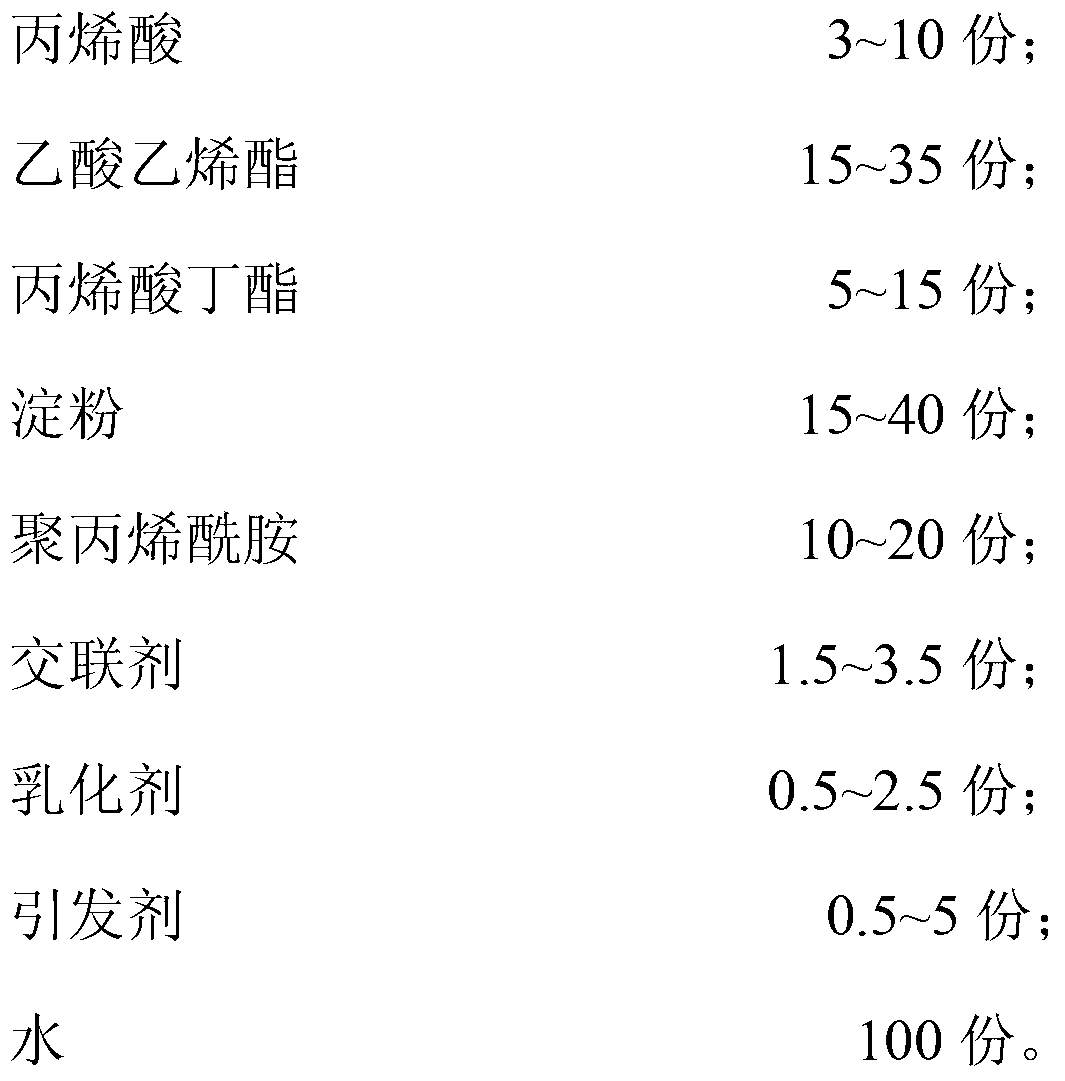

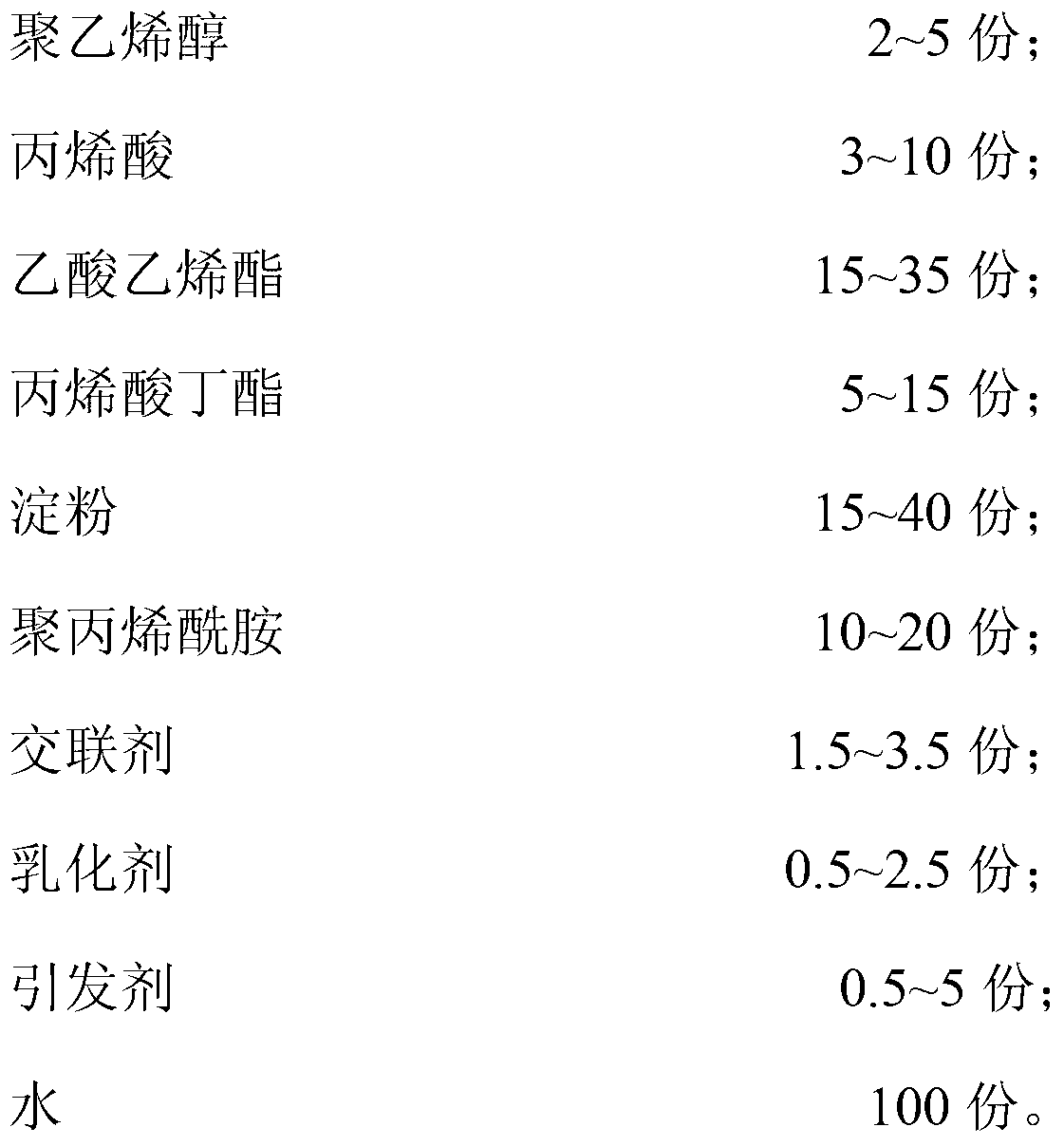

[0029] Prepare the preparation method of solid type chemical dust suppressant of the present invention, comprise the steps:

[0030] First prepare the solid chemical dust suppressant:

[0031] Add 2-5 parts by mass of polyvinyl alcohol and 100 parts of water into the reaction kettle equipped with a stirrer, thermometer and dropping funnel, raise the temperature to 90°C and start the stirrer to stir until the polyvinyl alcohol is completely dissolved Cool down to 60-70°C. Then add 3-10 parts of acrylic acid, 15-35 parts of vinyl acetate and 1 / 3 of 5-15 parts of butyl acrylate, and 0.5-2.5 parts of all emulsifiers to fully emulsify. After 20 minutes, add 0.5-5 parts of initiator for reaction, adjust the temperature to 70-85°C, add the remaining 2 / 3 monomers of acrylic acid, vinyl acetate and butyl acrylate dropwise from the dropping funnel for 2 hours. Then add 1.5-3.5 parts of cross-linking agent solution, 15-40 parts of starch and 10-20 parts of polyacrylamide, and stir to f...

Embodiment 1

[0038] Add 2 parts of polyvinyl alcohol and 100 parts of water into the reaction kettle equipped with a stirrer, thermometer, and dropping funnel, raise the temperature to 90°C and start the stirrer to stir, and cool down to 60°C after the polyvinyl alcohol is completely dissolved. Add 3 parts of acrylic acid, 15 parts of vinyl acetate and 1 / 3 of 15 parts of butyl acrylate, and 0.5 part of emulsifier sodium dodecylbenzenesulfonate to fully emulsify. After 20 minutes, add 0.5 parts of initiator ammonium persulfate to react, adjust the temperature to 85°C, add 2 parts of remaining 2 / 3 monomer acrylic acid, 10 parts of vinyl acetate and 10 parts of butyl acrylate dropwise from the dropping funnel, drop Add time 2h. Add 1.5 parts of cross-linking agent glycerol solution, 15 parts of starch and 20 parts of polyacrylamide, and stir to fully react for 1 hour. The pH of the reaction solution was adjusted to 7 with aqueous sodium hydroxide solution, and the reaction was stopped to obt...

Embodiment 2

[0041] Add 5 parts of polyvinyl alcohol and 100 parts of water into the reaction kettle equipped with a stirrer, thermometer, and dropping funnel, raise the temperature to 90°C and start the stirrer to stir, and cool down to 70°C after the polyvinyl alcohol is completely dissolved. Add 10 parts of acrylic acid, 25 parts of vinyl acetate and 1 / 3 of 5 parts of butyl acrylate, and 2 parts of emulsifier sodium lauryl sulfate to fully emulsify. After 20 minutes, add 1.5 parts of 30% hydrogen peroxide aqueous solution as the initiator to react, adjust the temperature to 70°C, add 6.67 parts of the remaining 2 / 3 monomer acrylic acid, 16.67 parts of vinyl acetate and butyl acrylate dropwise from the dropping funnel 3.34 parts, dropwise time 2h. Add 3.5 parts of cross-linking agent N,N-methylenebisacrylamide, 40 parts of starch and 10 parts of polyacrylamide, and stir to make it fully react for 2 hours. The pH of the reaction solution was adjusted to 7 with aqueous sodium hydroxide so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com