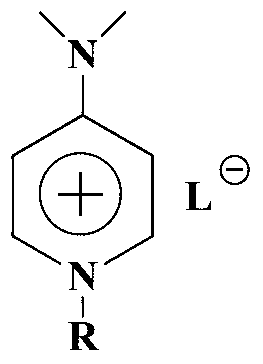

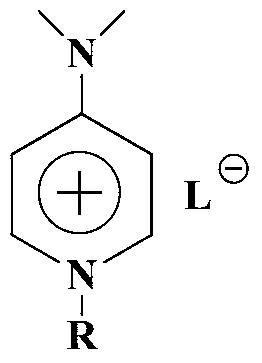

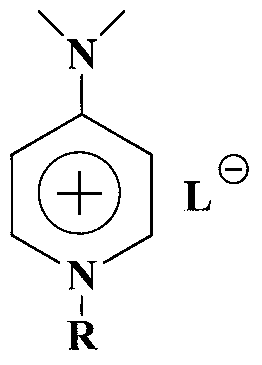

Method of applying dimethylamino modified pyridine ionic liquid in deep sulfur removal of oil

An ionic liquid and dimethylamine-based technology, which is applied in the field of pyridine ionic liquids and deep desulfurization of oil products, can solve the problems of fuel oil solubility increase, harsh conditions, high cost, etc., and achieve improved distribution coefficient, high distribution coefficient, The effect of broadening the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.0g [C 2 4 DMAPy][N(CN) 2 ] was added to 1.0g simulated gasoline (the simulated gasoline was composed of 25% toluene, 30% hexene, 45% n-octane and thiophene with a sulfur content of 500ppm), at this time the ionic liquid was in the lower layer, the oil product was in the upper layer, and the Stir at room temperature for 30 minutes, stand still for 5 minutes to separate the simulated gasoline, and conduct gas chromatography analysis on the simulated gasoline after extraction and desulfurization. The sulfur content in the simulated gasoline is reduced to 261ppm, and the desulfurization rate of the simulated gasoline is calculated to be 47.8%. The extracted ionic liquid is back-extracted with carbon tetrachloride, the regenerated ionic liquid can be reused, and the extracted carbon tetrachloride is subjected to vacuum distillation at 333K to obtain regenerated carbon tetrachloride. 1.0g [C 2 4 DMAPy][N(CN) 2 ] with 1.0g of 97 # Gasoline was mixed, stirred at room te...

Embodiment 2

[0035] 1.0g [C 2 4 DMAPy][N(CN) 2 ] into 1.0g of simulated gasoline (the composition of simulated gasoline is 40% hexene, 60% n-octane and thiophene with a sulfur content of 500ppm), at this time, the ionic liquid is in the lower layer, and the oil product is in the upper layer, and stirred at room temperature After standing for 5 minutes, the simulated gasoline was separated, and the simulated gasoline after extraction and desulfurization was analyzed by gas chromatography. The sulfur content in the simulated gasoline was reduced to 232ppm, and the desulfurization rate of the simulated gasoline was calculated to be 53.4%. The extracted ionic liquid is back-extracted with carbon tetrachloride, the regenerated ionic liquid can be reused, and the extracted carbon tetrachloride is subjected to vacuum distillation at 333K to obtain regenerated carbon tetrachloride. The filtrate will be 1.0g [C 2 4 DMAPy][N(CN) 2 ] with 1.0g of 97 # Gasoline was mixed, stirred at room tempera...

Embodiment 3

[0037] 1.0g [C 2 4 DMAPy][N(CN) 2 ] was added to 5.0g simulated gasoline (the simulated gasoline was composed of 25% toluene, 30% hexene, 45% n-octane and thiophene with a sulfur content of 500ppm), at this time the ionic liquid was in the lower layer, the oil product was in the upper layer, and the Stir at room temperature for 30 minutes, stand still for 5 minutes to separate the simulated gasoline, and conduct gas chromatography analysis on the simulated gasoline after extraction and desulfurization. The sulfur content in the simulated gasoline is reduced to 408ppm, and the desulfurization rate of the simulated gasoline is calculated to be 18.2%. The extracted ionic liquid is back-extracted with carbon tetrachloride, the regenerated ionic liquid can be reused, and the extracted carbon tetrachloride is subjected to vacuum distillation at 333K to obtain regenerated carbon tetrachloride. 1.0g [C 2 4 DMAPy][N(CN) 2 ] with 1.0g of 97 # Gasoline was mixed, stirred at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com