Converter steelmaking method and converter steelmaking device

A converter steelmaking and gas source technology, applied in the manufacture of converters, etc., can solve the problems of large consumption of oxygen and coke, more slag overflow, and large consumption of oxygen, so as to reduce the consumption of coal and coke, ensure the transmission concentration, Continuous and uniform effect of powder spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

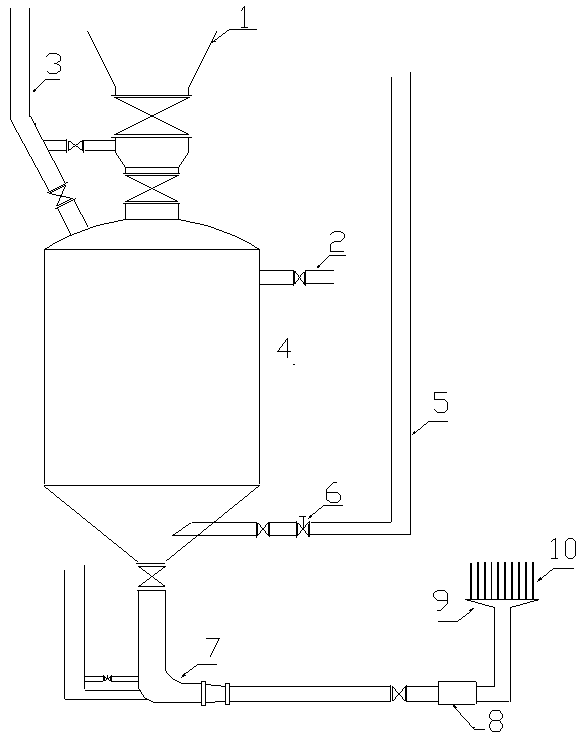

[0026] Such as figure 1 A kind of converter steelmaking device as shown, comprises blowing tank 4, mixer 7, conveying pipeline, secondary mixer 8 and special spray gun connected successively by blowing pipeline; The parts are horizontally connected to the inflation pipeline Ⅰ and the inflation pipeline Ⅱ5 equipped with the regulating valve 6, wherein the elbow of the mixer 7 is a large-angle elbow, and the elbow is made of an elbow lined with wear-resistant ceramic material, and the secondary mixer 8 and A distributor 9 and a powder spraying branch pipe 10 are installed between the special spray guns.

[0027] During operation, the dry high-grade concentrate powder with a moisture content of 0.7% and an iron content of 68% is weighed and then sent from the silo 1 to the injection tank 4, and the injection tank 4 is passed through a valve equipped with a regulating valve 6. Inflatable pipeline Ⅰ and nitrogen pipeline Ⅱ5 are connected to two gas sources, the gas source is nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com