A coal gangue circulating fluidized bed boiler

A technology of circulating fluidized bed and coal gangue, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc., which can solve the problem of inability to guarantee the bed temperature, affect the stable operation of the boiler, and inexhaustible fuel combustion and other problems, to achieve the effect of preventing short circuit of flue gas and reverse flow of return air, prolonging residence time and stabilizing fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

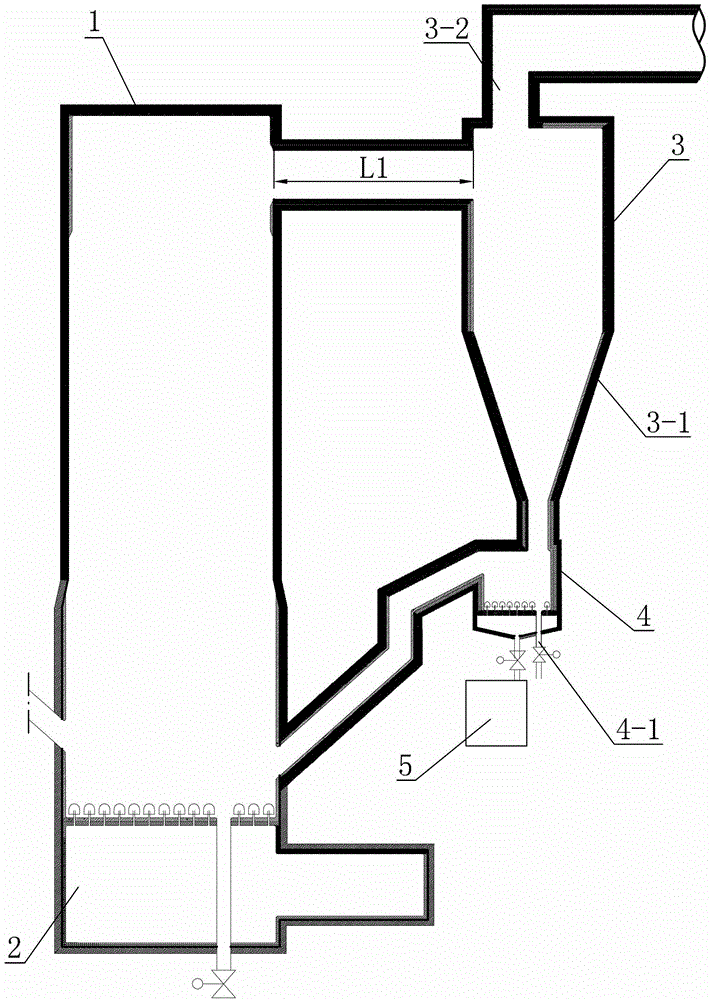

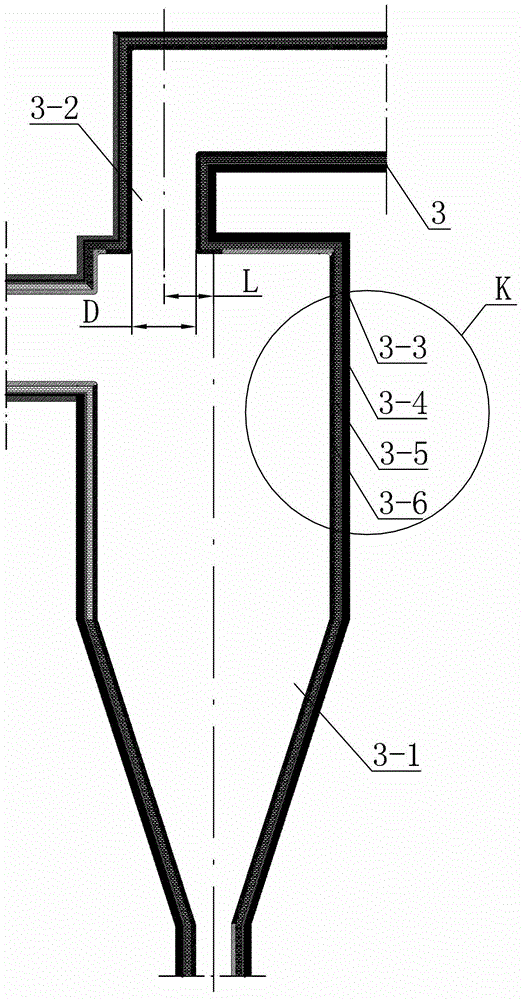

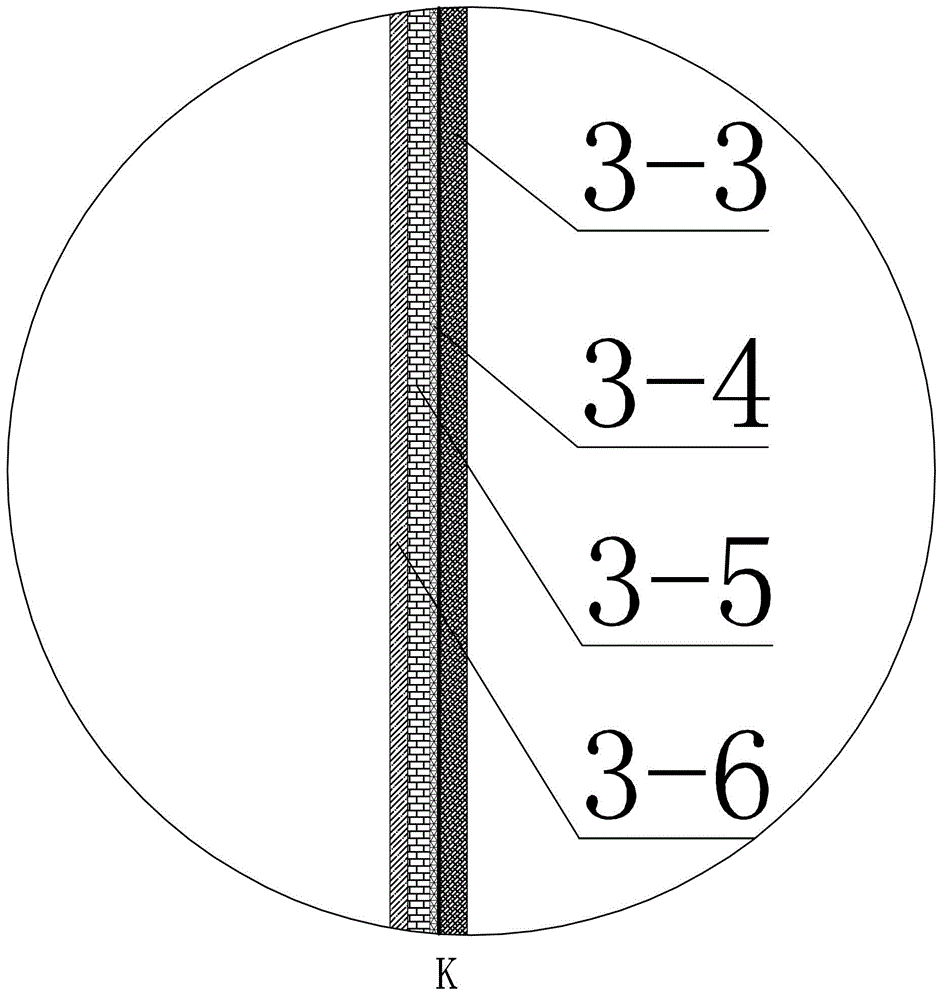

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Explain that a coal gangue circulating fluidized bed boiler in this embodiment includes a furnace 1, a water-cooled air chamber 2, a cyclone separator 3, a feeding device 4 and a feeding Roots blower 5, and the lower end of the feeding device 4 is communicated with a The return Roots blower 5 and the water-cooled air chamber 2 are fixedly connected to the lower end of the furnace 1, and the upper side wall of the furnace 1 is connected with a cyclone separator 3, and the cyclone separator 3 includes a separator main body 3-1 and a flue gas outlet cylinder 3 -2, the outer wall of the separator main body 3-1 is provided with thermal insulation rock wool 3-3, and the inner wall of the separator main body 3-1 is successively provided with aluminum silicate thermal insulation cotton board 3-4 and thermal insulation castable layer 3-5 and the wear-resistant castable layer 3-6, the flue gas outlet cylinder 3-2 of t...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 To illustrate, the flue gas outlet tube 3-2 of the cyclone separator 3 in this embodiment is rolled from wear-resistant and heat-resistant steel plates. Such design improves the quality of the cyclone separator and ensures the stable and reliable operation of the cyclone separator. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 To illustrate, the inner diameter D of the flue gas outlet cylinder 3-2 in this embodiment is 2.3-3.0 m. This design ensures smooth flow of flue gas. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com