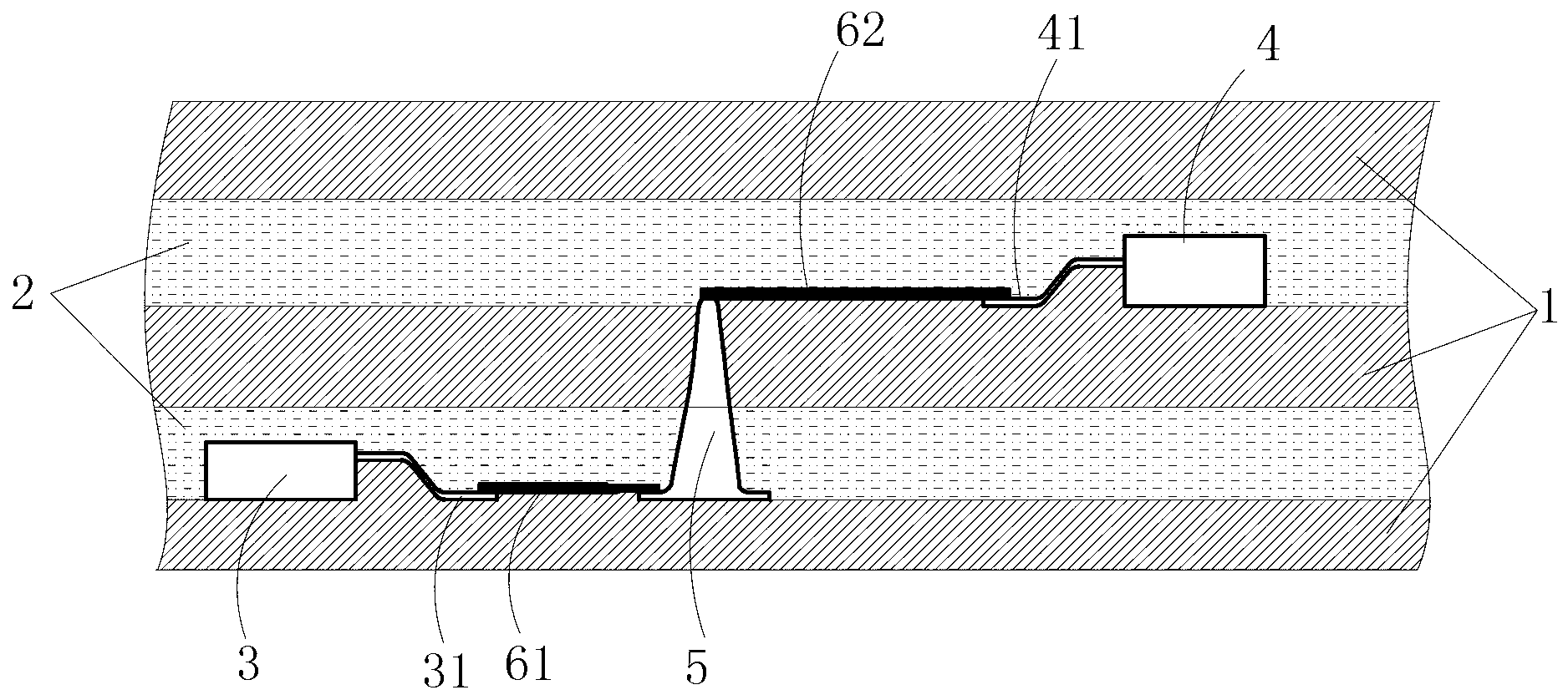

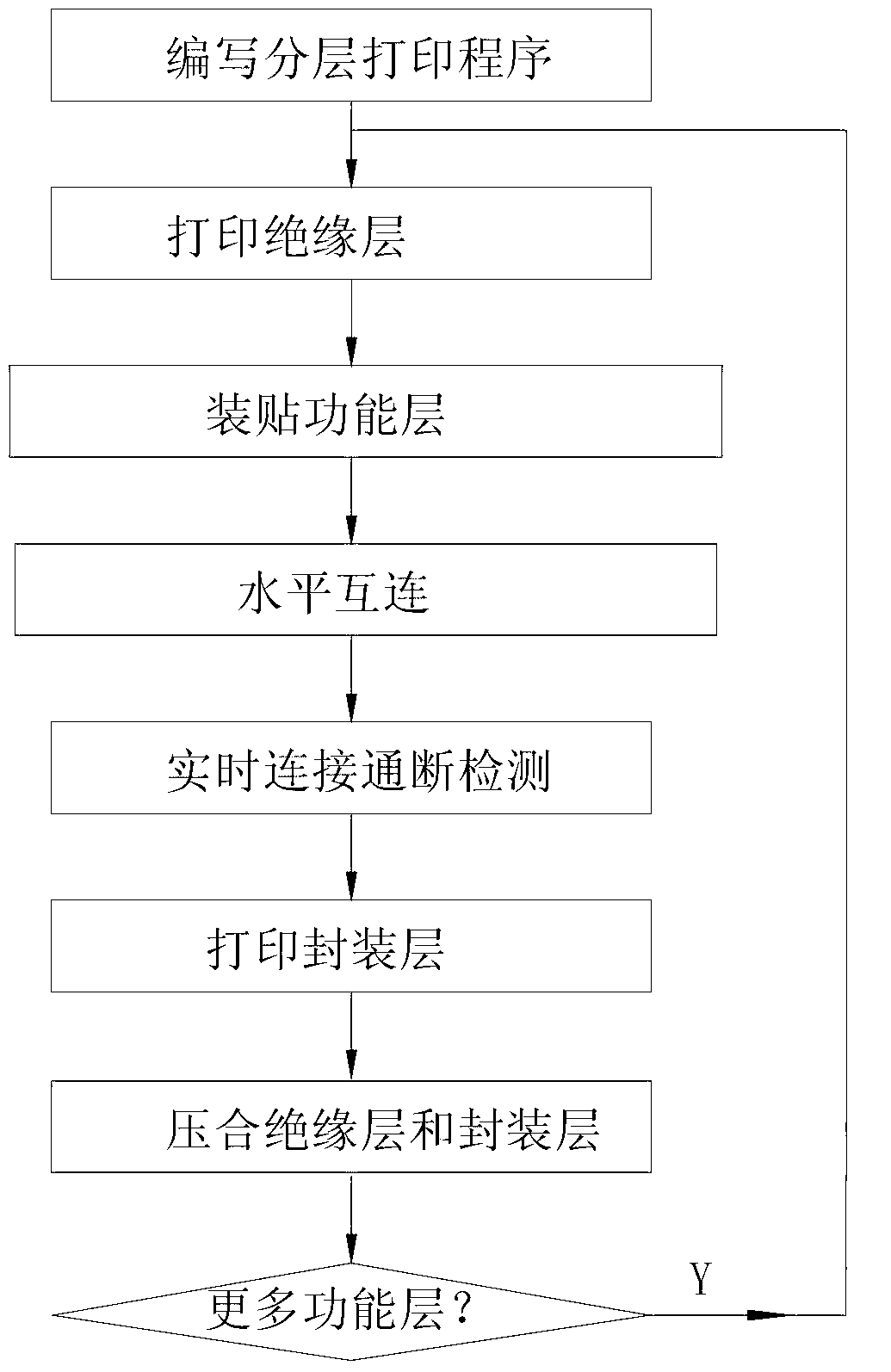

3D (Three Dimensional)-printing-based package substrate and manufacturing method thereof

A packaging substrate, 3D printing technology, applied in printed circuit manufacturing, multi-layer circuit manufacturing, semiconductor/solid-state device manufacturing, etc. problem, to achieve the effect of good industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] This application has been explained in the technical background, and the multilayer circuit board and the packaging substrate are no longer distinguished. This application regards a multilayer circuit board as a packaging substrate without embedded passive / active electronic devices. Therefore, in the present application, the packaging substrate includes a circuit board, especially a multilayer circuit board. Passive electronic devices include resistors, capacitors, inductors, etc. Active electronic devices include transistors, integrated circuits, chips and chip modules.

[0111] 3D printing technology has created a new concept of design and manufacturing.

[0112] One of the outstanding advantages of 3D printing technology is that it can realize parts made of functionally graded materials, and can directly manufacture parts with arbitrary complex structures. In particular, products that lose manufacturability due to complex three-dimensional structures inside, or pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com