Glass sheet with gradient refractive indexes and preparation method of sheet

A gradient refractive index and glass flake technology, which is applied in the field of glass flakes and its preparation, can solve the problems of high cost and difficulty in wide application, and achieve the effects of low cost, improved luminous efficiency, and a wide range of refractive index control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

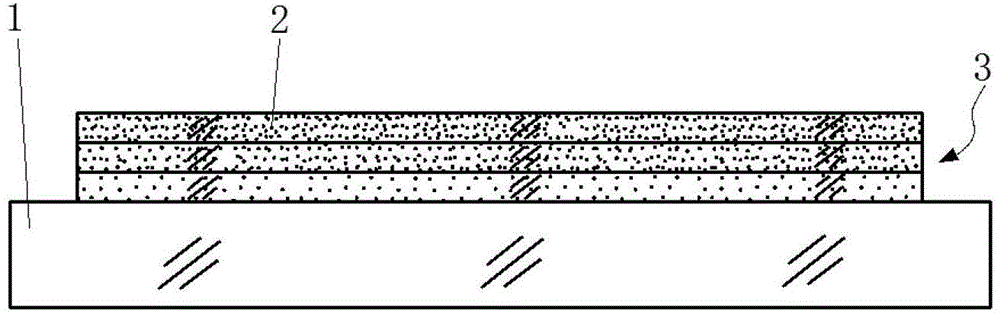

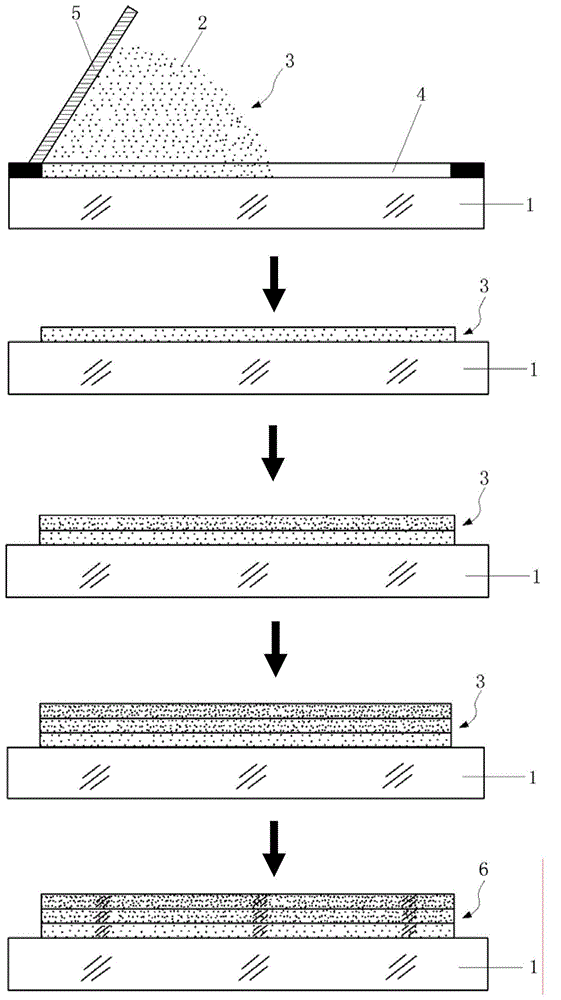

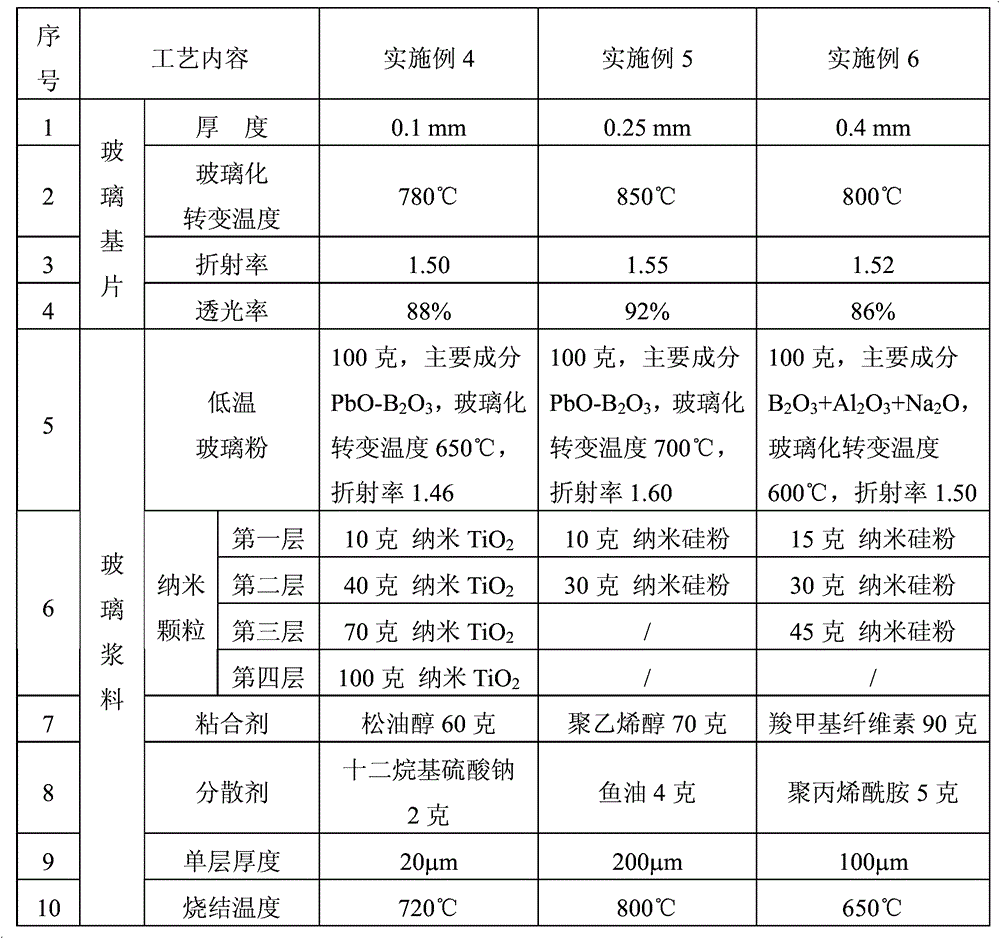

[0034] Such as figure 2 As shown, the process of this example is:

[0035] 1) Select borosilicate glass sheet 1 with a thickness of 0.5mm (model Pyrex 7740, glass transition temperature 821℃, refractive index 1.48, light transmittance greater than 85%), ultrasonically cleaned with acetone solution, and dried for backup use;

[0036] 2) Weigh 60 grams of terpineol, add 1 gram of cellulose and 10 grams of nano-TiO 2 Particles (average particle size of 5nm), ultrasonically stirred at 70 ℃ into a mixed solution, and then add 100 grams of low-temperature glass powder (the main component is PbO-B 2 O 3 , The glass transition temperature is 650℃, and the refractive index is 1.45), mixed and stirred in a ball mill for 30 minutes to prepare a homogeneous glass slurry 3;

[0037] 3) Using the screen printing process, a layer of glass paste layer 3 with a thickness of 50um is uniformly coated on the surface of the glass substrate 1;

[0038] 4) Increasing nano TiO sequentially 2 The dosage is ...

Embodiment 2

[0040] 1) Select a borosilicate glass sheet with a thickness of 1.0mm (glass transition temperature of 640°C, refractive index of 1.40, and light transmittance greater than 80%), ultrasonically clean with acetone solution, and dry for use;

[0041] 2) Weigh 80 grams of polyvinyl alcohol, add 3 grams of fish oil and 5 grams of nano silicon powder (average particle size of 20nm), ultrasonically stir to form a solution at 70°C, and then add 100 grams of low temperature glass powder (the main component is B 2 O 3 +Al 2 O 3 +Na 2 O, the glass transition temperature is 450°C, and the refractive index is 1.40), mixed and stirred in a ball mill for 60 minutes to prepare a homogeneous glass slurry;

[0042] 3) Using a screen printing process to coat the surface of the glass substrate to form a glass paste layer with a thickness of 100um;

[0043] 4) Increase the content of nano silicon powder to 20 grams, and repeat the above steps 2) and 3);

[0044] 5) Place the coated glass substrate in a hi...

Embodiment 3

[0046] 1) Choose a borosilicate glass sheet with a thickness of 0.3mm (glass transition temperature of 780°C, refractive index of 1.60, and light transmittance greater than 90%), ultrasonically clean with acetone solution, and dry for use;

[0047] 2) Weigh 100 grams of carboxymethyl cellulose, add 5 grams of methyl pentanol and 10 grams of nano-TiO 2 (Average particle size is 40nm), ultrasonically stirred at 60℃ to form a solution, and then add 100 grams of boroaluminate glass powder (the main component is B 2 O 3 +Al 2 O 3 +Na 2 O, the glass transition temperature is 500°C, and the refractive index is 1.56), mix and stir in a ball mill for 60 minutes to prepare a homogeneous glass slurry;

[0048] 3) Using a screen printing process to coat a glass paste layer with a performance thickness of 80um on the surface of the glass substrate;

[0049] 4) Increasing nano TiO sequentially 2 The dosage is 40 grams and 70 grams, repeat the above steps 2) and 3);

[0050] 5) Put the coated glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com