Preparation method of m-hydroxybenzaldehyde

A hydroxybenzaldehyde and temperature control technology, which is applied in the preparation of carbon-based compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of difficult product quality control, difficult clean production, complex production process, etc., and achieve product The effect of stable weight control, easy product weight and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

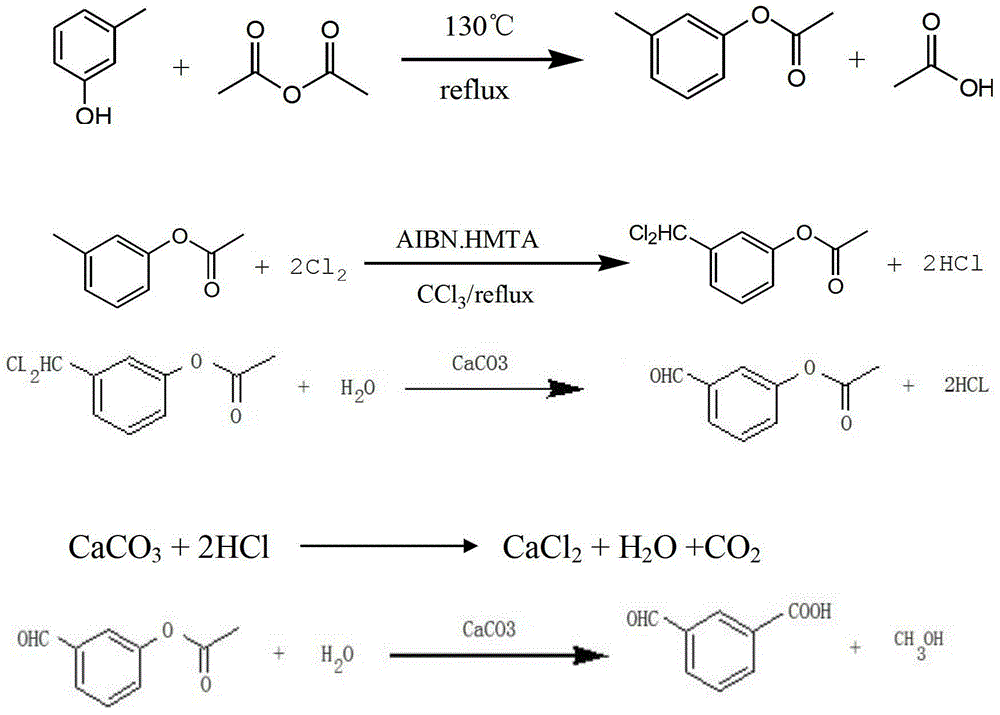

[0022] The preparation method of m-hydroxybenzaldehyde comprises an esterification section, a chlorination section, a distillation section, a hydrolysis section, a refining section and a drying section, and the specific steps are as follows:

[0023] (1) Esterification section

[0024] Put 400kg of m-cresol and 460kg of acetic anhydride into a 2000L glass-lined reactor by weight, and slowly raise the temperature. When the temperature in the pot reaches 130°C, heat preservation is started, and the temperature is kept at 130°C for 4 hours; At the end, atmospheric pressure distillation is carried out to collect the by-product acetic acid, and the acetic acid is put into storage after passing the analysis; then the open cooling is lowered to 90°C, the crude ester is pumped into the esterification distillation pot to be distilled, the mechanical vacuum pump is turned on, and the vent valve is closed to make the whole The distillation system is in a vacuum state, open the pumping va...

Embodiment 2

[0037] The preparation method of m-hydroxybenzaldehyde comprises an esterification section, a chlorination section, a distillation section, a hydrolysis section, a refining section and a drying section, and the specific steps are as follows:

[0038] (1) Esterification section

[0039]Put 500kg of m-cresol and 480kg of acetic anhydride into a 2000L glass-lined reactor by weight, and slowly raise the temperature. When the temperature in the pot reaches 130°C, heat preservation is started, and the temperature is kept at 135°C for 4.5 hours. At the end, carry out atmospheric distillation to collect the by-product acetic acid, and store the acetic acid after passing the analysis; then turn the cooling down to 95°C, pump the crude ester into the esterification distillation pot to be distilled, turn on the mechanical vacuum pump, close the vent valve, and make the whole The distillation system is in a vacuum state, open the pumping valve, pump the crude ester into the distillation p...

Embodiment 3

[0051] The preparation method of m-hydroxybenzaldehyde comprises an esterification section, a chlorination section, a distillation section, a hydrolysis section, a refining section and a drying section, and the specific steps are as follows:

[0052] (1) Esterification section

[0053] Put 600kg of m-cresol and 500kg of acetic anhydride into a 2000L glass-lined reactor by weight, and slowly raise the temperature. When the temperature in the pot reaches 130°C, heat preservation is started, and the temperature is kept at 140°C for 5 hours; At the end, atmospheric pressure distillation is carried out to collect the by-product acetic acid, and the acetic acid is put into storage after the analysis is qualified; then the open cooling is lowered to 100°C, the crude ester is pumped into the esterification distillation pot to be distilled, the mechanical vacuum pump is turned on, and the vent valve is closed to make the whole The distillation system is in a vacuum state, open the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com