Cationic flocculant and preparation method thereof

A cationic flocculant and catalyst technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of instability, high viscosity, release of harmful formaldehyde gas, etc., to achieve good stability, good flocculation effect, pH resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

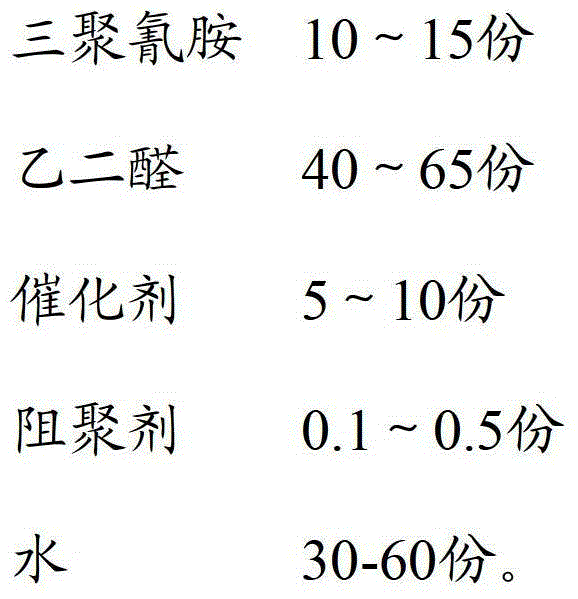

[0030] A cationic flocculant prepared by the following method:

[0031] 1) Add 30 parts of water into the reaction kettle, adjust the pH value to 9, then add 40 parts of glyoxal, stir and heat up to 30°C;

[0032] 2) Add 10 parts of melamine to the above reaction kettle, stir while adding, then add 5 parts of catalyst, stir, heat up to 65°C and react for 2 hours;

[0033] 3) Control the temperature in step 2) to remain unchanged, add 0.1 part of polymerization inhibitor, and stir for 1 hour until the reaction is complete;

[0034] 4) Cool to room temperature.

Embodiment 2

[0036] A cationic flocculant prepared by the following method:

[0037] 1) Add 30 parts of water into the reaction kettle, adjust the pH value to 9, then add 50 parts of glyoxal, stir and heat up to 30°C;

[0038] 2) Add 12 parts of melamine to the above reaction kettle, stir while adding, then add 5 parts of catalyst, stir, heat up to 60°C and react for 4 hours;

[0039] 3) Control the temperature in step 2) to remain unchanged, add 0.3 parts of polymerization inhibitor, and stir for 1 hour until the reaction is complete;

[0040] 4) Cool to room temperature.

Embodiment 3

[0042] A cationic flocculant prepared by the following method:

[0043] 1) Add 60 parts of water into the reaction kettle, adjust the pH value to 10, then add 65 parts of glyoxal, stir and raise the temperature to 40°C;

[0044] 2) Add 15 parts of melamine to the above reaction kettle, stir while adding, then add 10 parts of catalyst, stir, heat up to 65°C to react, and react for 2 hours;

[0045] 3) Control the temperature in step 2) to remain unchanged, add 0.1 part of polymerization inhibitor, and stir for 1 hour until the reaction is complete;

[0046] 4) Cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com