Silicate inorganic aqueous binder

A water-based adhesive and silicate technology, which is applied in the direction of inorganic adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of harmful gas emissions, high price, poor water resistance, etc., and achieve improved water resistance , Optimize the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

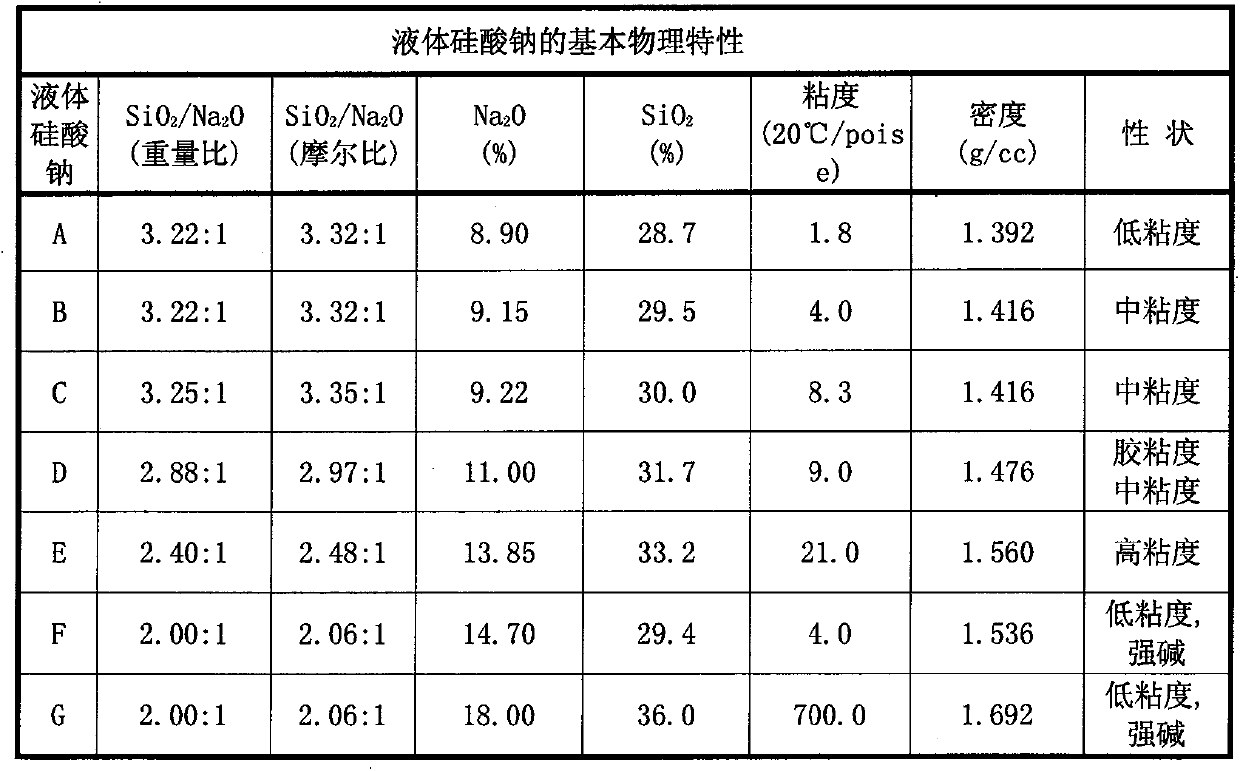

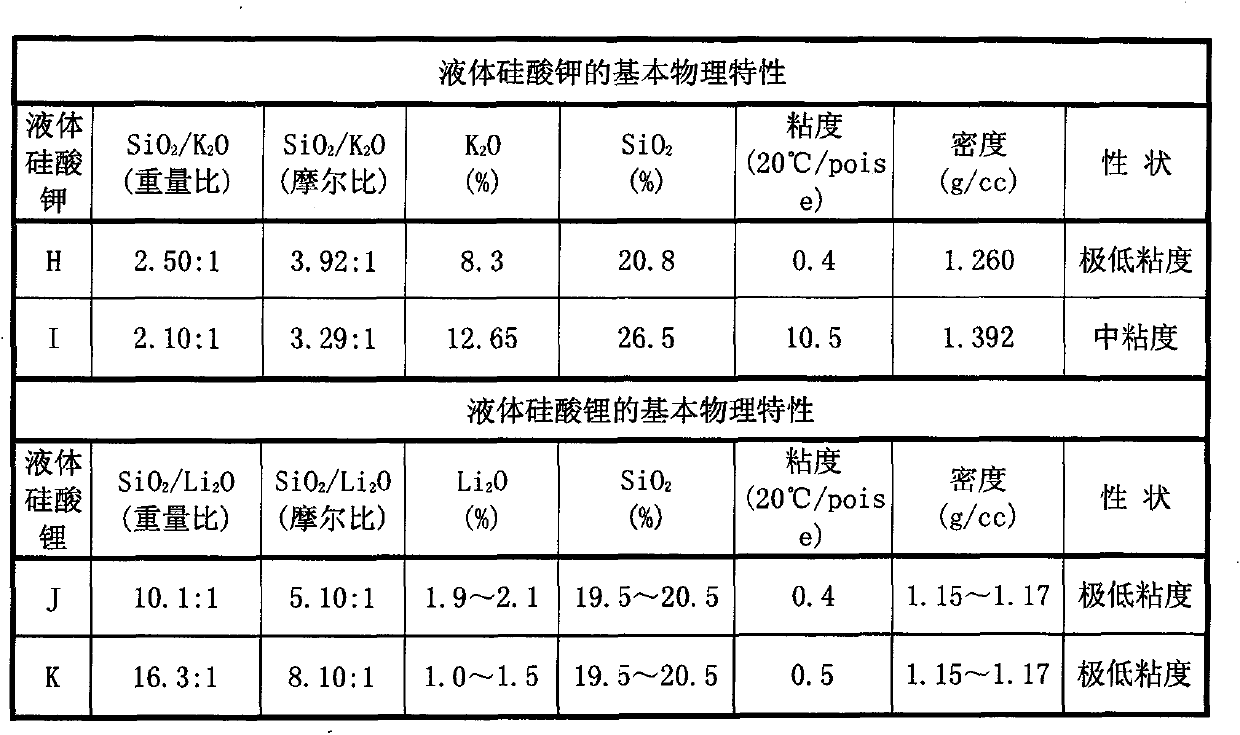

[0054] Get liquid sodium silicate 37g (SiO 2 / Na 2 The molar ratio of O is 3.20), liquid potassium silicate 9g (SiO 2 / K 2 The molar ratio of O is 3.22), liquid lithium silicate 7g (SiO 2 / Li 2 The molar ratio of O is 5.1) and 2.5 g of deionized water added for improving the intercommunication between silicates, 6 g of silica sol (30% content of SiO 2 , average particle size 10nm). Put these substances into a mixer with a scraper and stir for more than 30 minutes to achieve uniform stirring. Slowly add 6.5 grams of 10% phosphoric acid aqueous solution with a powder-liquid funnel within 60 minutes, stir while adding, and then add 2 grams of ore The material fibers were stirred for 30 minutes to fully disperse to obtain an inorganic water-based adhesive. The mineral fiber used in this example is Lapinus702K2-Roxull000 (Lapinus Fibers, Netherlands).

Embodiment 2

[0056] Manufactured according to the preparation method of Example 1, the phosphoric acid aqueous solution in the acid hardening process is replaced by the formic acid water solvent diluted by 10%, and the other is unchanged, and the inorganic water-based adhesive is obtained.

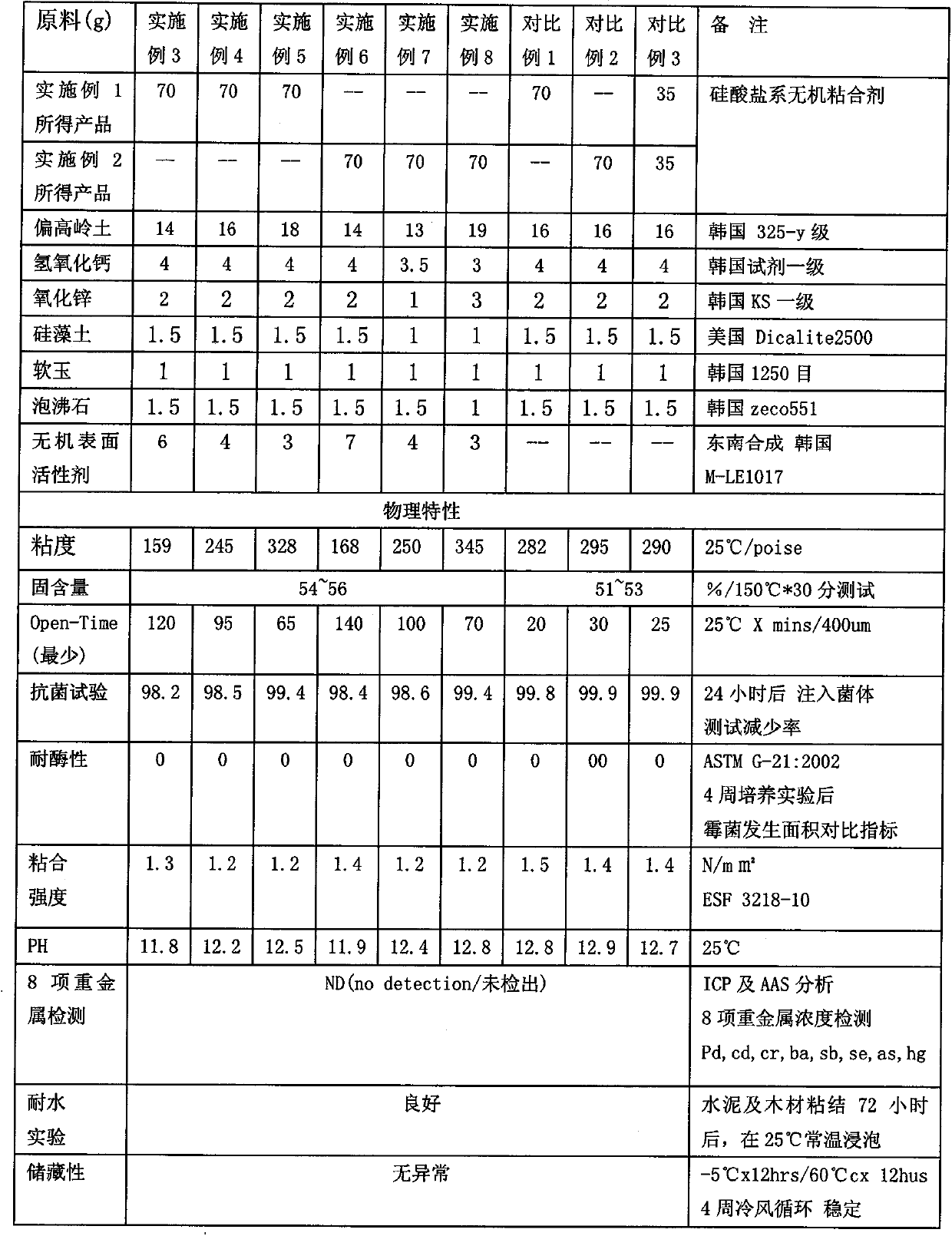

[0057] Other embodiments and comparative examples are shown in Table 3.

[0058] Table 3 other embodiments and comparative examples

[0059]

[0060] As shown in Table 3, inorganic water-based adhesives using inorganic surfactants do not affect antibacterial and antifungal functions. The functional mineral raw materials used and the structure hardened by hydration reaction improve (ensure) the water resistance of the adhesive. The adhesive of the invention has heat-resistant stability, which is different from the existing water-based adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com