High-entropy amorphous alloy material and preparation method thereof

An amorphous alloy and high-entropy technology, applied in the field of high-entropy amorphous alloy materials and their preparation, can solve problems such as difficulties and achieve the effects of high wear resistance, corrosion resistance, and high thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: prepare Ti 20 Zr 20 Ni 20 Cu 20 be 20 High entropy bulk amorphous alloy

[0041] First, batching is carried out according to the chemical composition ratio, and then the master alloy ingot is made by repeated melting in a vacuum electric arc furnace. Under the condition of Ar gas protection after vacuum extraction, the master alloy is placed in the induction furnace of the rapid solidification device to be melted, and after melting, it is suction-cast into a copper mold with a cavity diameter of 3 mm, and cooled to obtain the Ti 20 Zr 20 Ni 20 Cu20 be 20 High-entropy bulk amorphous alloy rods, and their microstructure, thermal properties and mechanical properties were tested by XRD, DSC and compression experiments.

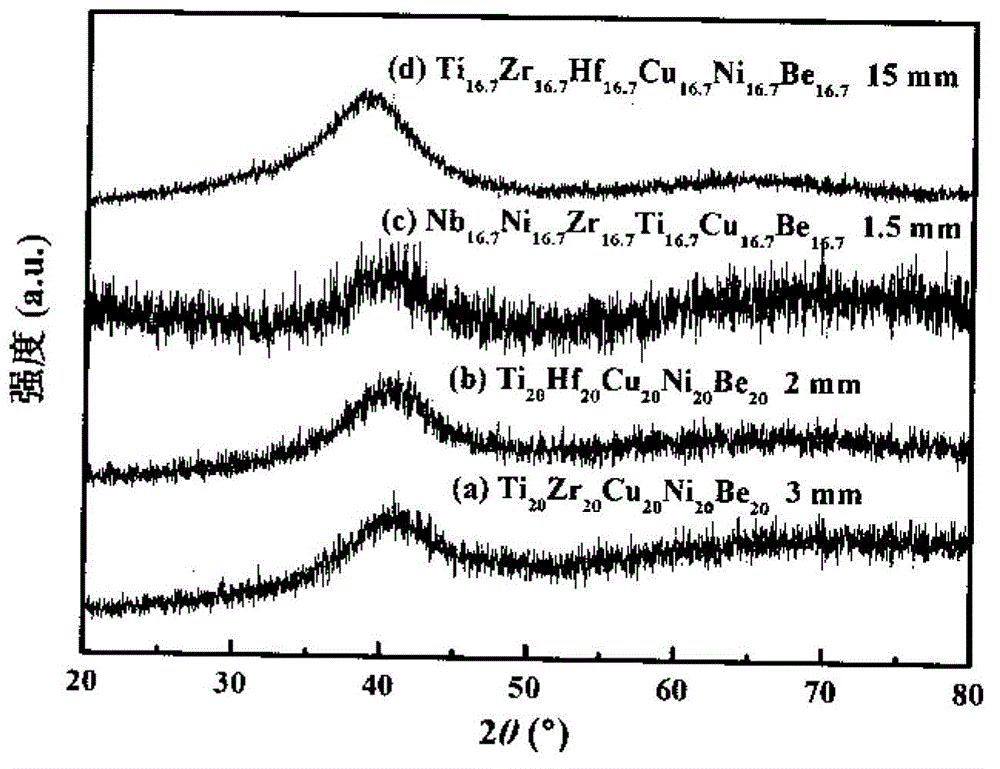

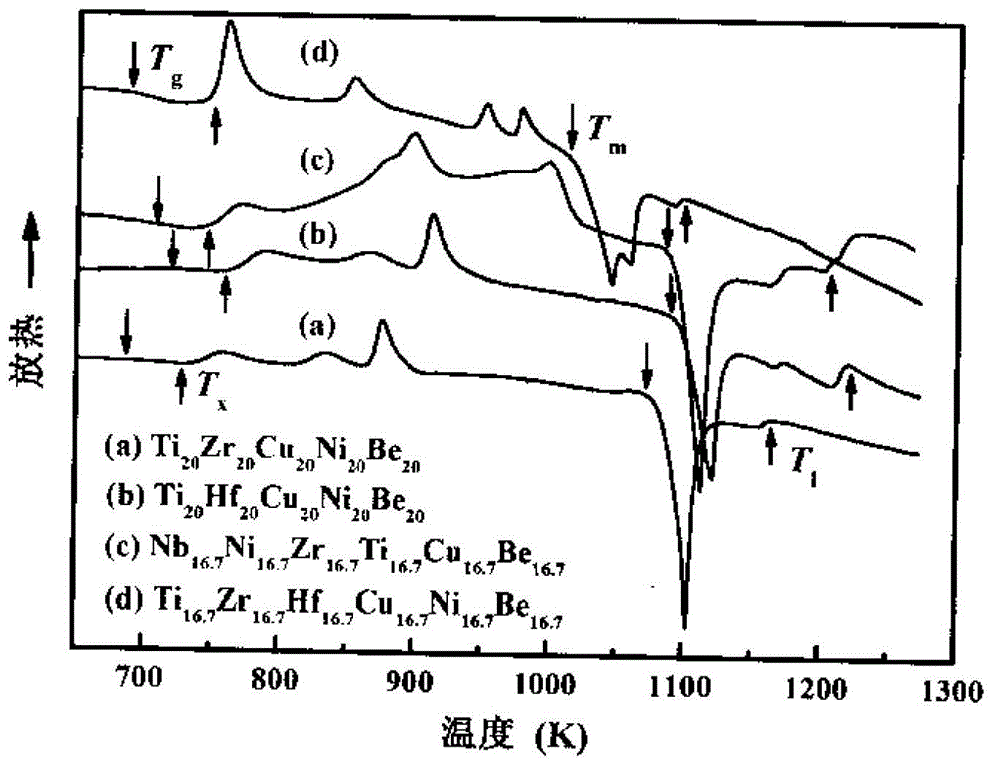

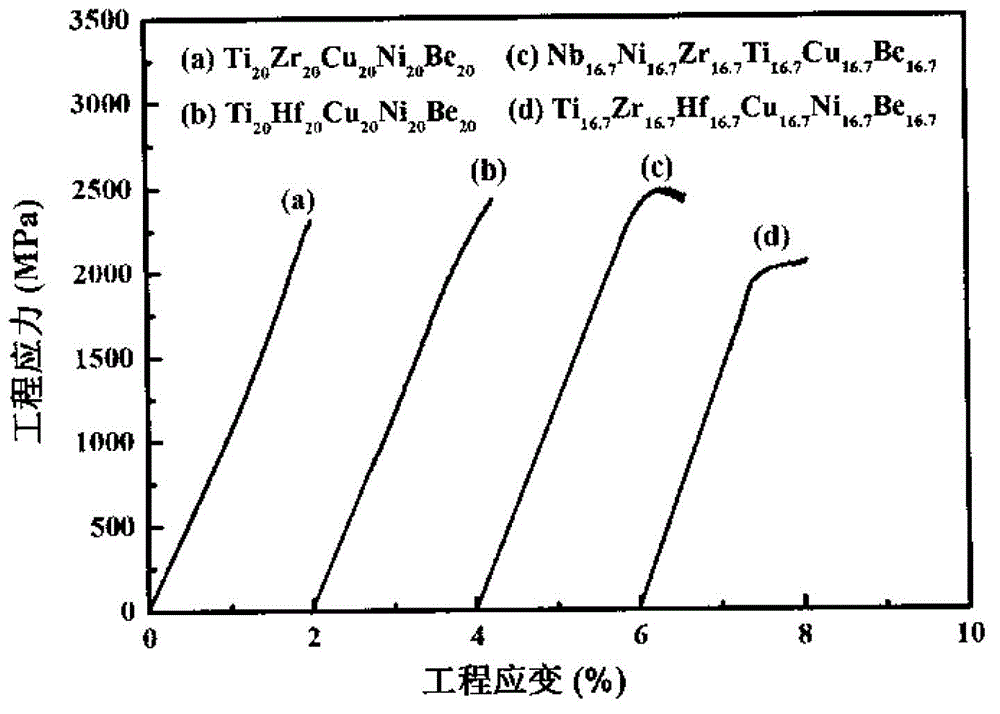

[0042] figure 1 (a) is Ti in embodiment 1 20 Zr 20 Ni 20 Cu 20 be 20 The high-entropy bulk amorphous alloy obtained the X-ray diffraction pattern of Φ3mm rod by copper mold casting method. In the pattern, there are only diffuse s...

Embodiment 2

[0043] Embodiment 2: prepare Ti 20 f 20 Ni 20 Cu 20 be 20 High entropy bulk amorphous alloy

[0044] First, batching is carried out according to the chemical composition ratio, and then the master alloy ingot is made by repeated melting in a vacuum electric arc furnace. Under the condition of Ar gas protection after vacuum extraction, the master alloy is placed in the induction furnace of the rapid solidification device to be melted, and after melting, it is suction-cast into a copper mold with a cavity diameter of 2 mm, and cooled to obtain the Ti 20 f 20 Ni 20 Cu 20 be 20 High-entropy bulk amorphous alloy rods, and their microstructure, thermal properties and mechanical properties were tested by XRD, DSC and compression experiments.

[0045] figure 1 (b) is that composition is Ti in embodiment 2 20 f 20 Ni 20 Cu 20 be 20 The high-entropy bulk amorphous alloy obtained the X-ray diffraction spectrum of the Φ2mm rod by copper mold casting method. In the spectrum,...

Embodiment 3

[0046] Embodiment 3: Preparation of Nb 16.7 Ni 16.7 Zr 16.7 Ti 16.7 Cu 16.7 be 16.7 High entropy bulk amorphous alloy

[0047] First, batching is carried out according to the chemical composition ratio, and then the master alloy ingot is made by repeated melting in a vacuum electric arc furnace. Under the condition of Ar gas protection after vacuum extraction, the master alloy is placed in the electric arc furnace of the rapid solidification device to melt it, and then sucked into copper molds with different cavity diameters, and cooled to obtain the Nb 16.7 Ni 16.7 Zr 16.7 Ti 16.7 Cu 16.7 be 16.7 High-entropy bulk alloy rods (the subscript 16.7 is an approximate value obtained from 100 / 6), and its structure, thermal properties and mechanical properties were tested by XRD, DSC and compression experiments.

[0048] figure 1 (c) is that composition is Nb in embodiment 3 16.7 Ni 16.7 Zr 16.7 Ti 16.7 Cu 16.7 be 16.7 The X-ray diffraction spectrum of the Φ1.5mm ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Onset crystallization temperature | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com