A control circuit for led AC drive

A technology for driving control circuits and control circuits, which is applied in the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of reducing the power efficiency of lamps, low power consumption of power supply circuits, insufficient power supply current, etc., and achieves low cost and circuit. High efficiency and small temperature rise of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

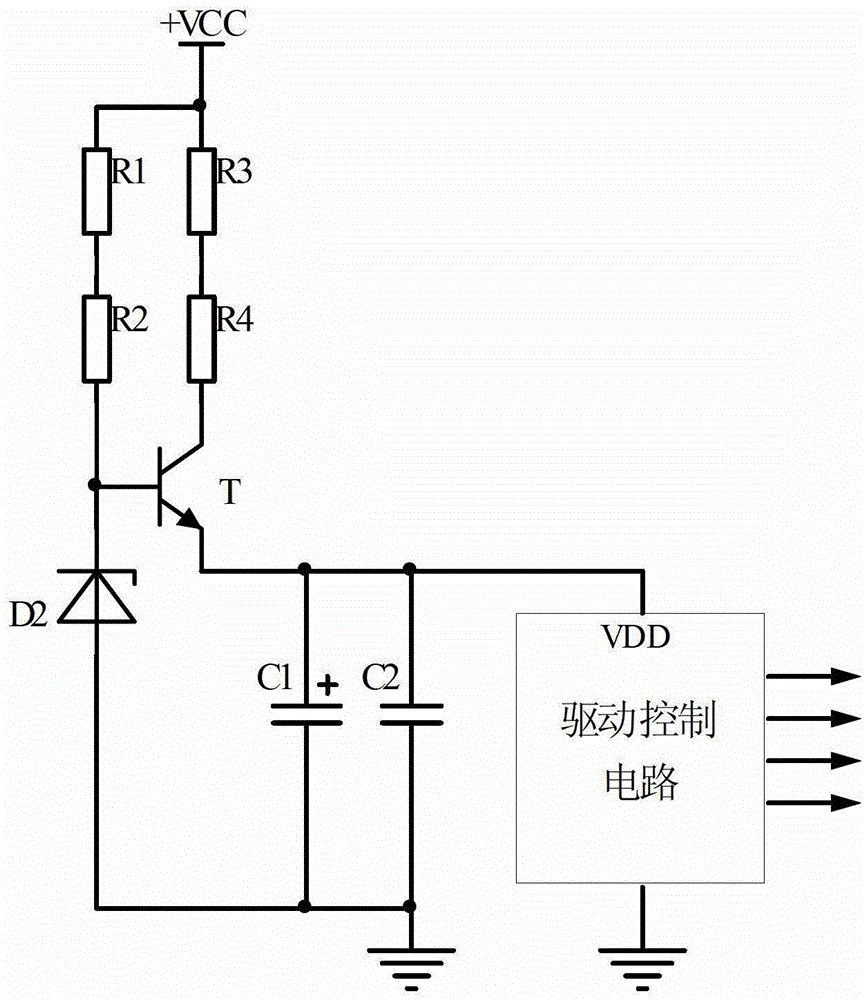

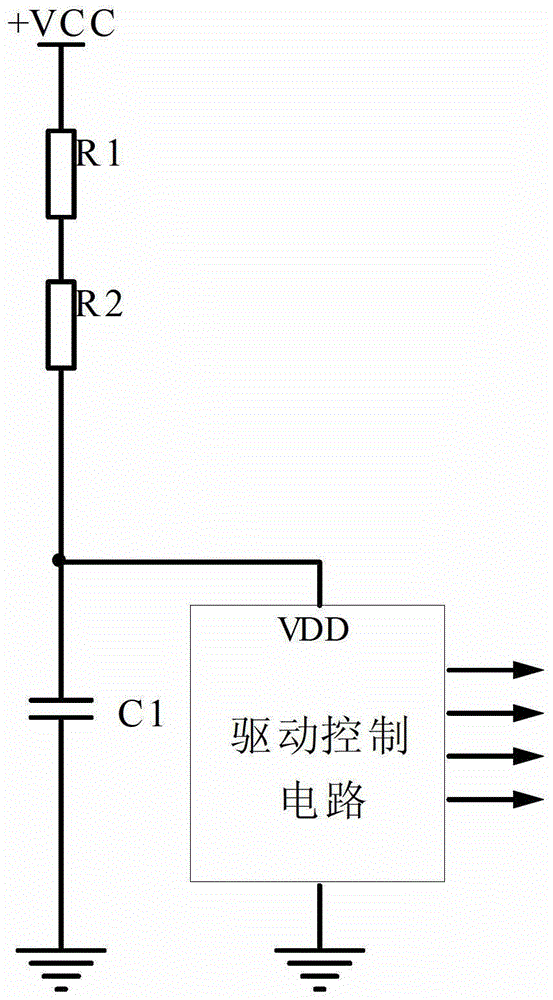

[0024] The structure diagram of the present invention is as Figure 4 As shown, the control circuit for LED AC drive of the present invention includes a power-taking circuit 1, a drive control circuit 2, an isolation circuit 3, and a filter / energy storage circuit 4, wherein the power-taking circuit 1 includes a first LED chip group 5, One pole of the isolation circuit 3 is connected to the positive pole of the first LED chipset 5, and the other pole is connected to the power supply terminal VDD of the drive control circuit 2; the filter / energy storage circuit 3 is connected in parallel to the power supply terminal VDD of the drive control circuit 2 and the common potential Between the reference point ground COM, the negative pole of the first LED chip group 5 is connected to the common potential reference point ground COM; the working power supply of the drive control circuit 2 is obtained by the forward voltage of the first LED chip group 5 through the isolation circuit 3 and ...

Embodiment 2

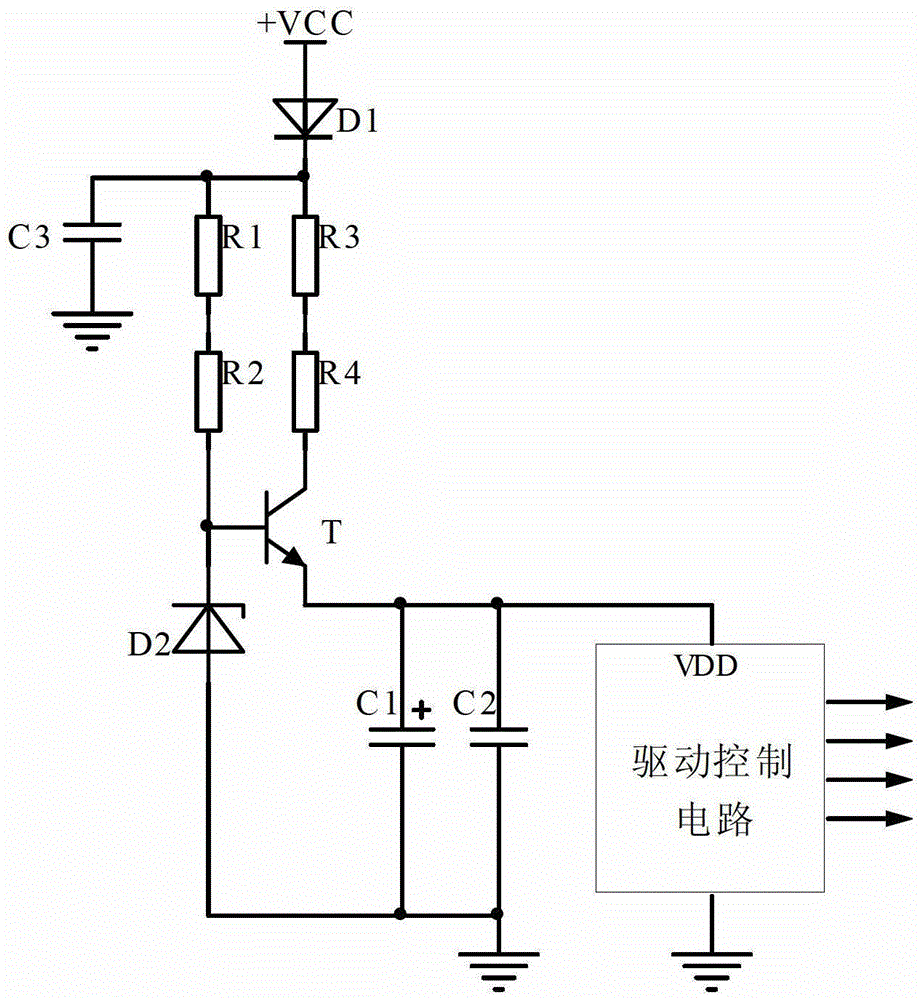

[0037] Figure 7It is the schematic diagram of the drive control circuit of the 30W non-electrolytic capacitor LED AC drive mode lamp. In this embodiment, the second LED chipset 6 includes several LED chips Di1, Di2, Di3, Di4...Dik, the first LED chipset 5 includes 3 LED chips D1, D2, D3 connected in series, the isolation circuit 3 is an isolation diode D, the working circuit of the first LED chipset 5 is 150mA, and the isolation diode D is a Schottky diode with low conduction voltage. The positive pole is connected to the positive pole of the first LED chipset 5, and the negative pole is connected to the power supply terminal VDD of the drive control circuit 2. The filter / energy storage circuit 4 is composed of three ceramic chip capacitors C1, C2, and C3 with a capacity of 22 μF and a withstand voltage of 16V. , the filter / energy storage capacitor C is connected in parallel between the power supply terminal VDD of the drive control circuit 2 and the common potential referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com