Resin composition for sealing an optical semiconductor and optical semiconductor device using said resin composition

A technology for optical semiconductor devices and resin compositions, which is applied to semiconductor devices, semiconductor/solid-state device parts, epoxy resin adhesives, etc. Small fluctuation, excellent brightness stability, high heat resistance and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

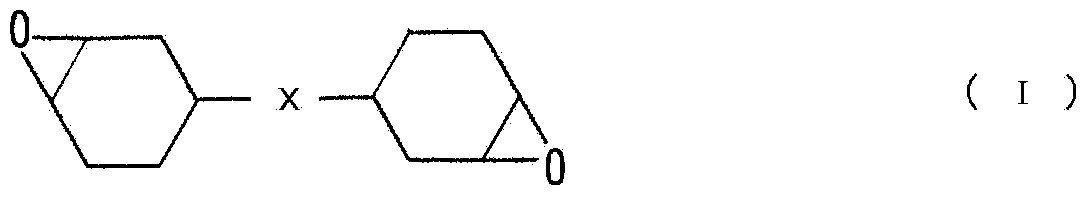

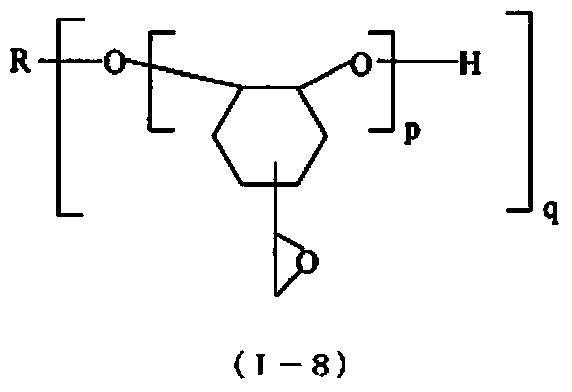

[0105] As the cycloaliphatic epoxy resin, 50 parts by weight of "CELLOXIDE 2021P" (trade name) manufactured by Daicel Chemical Industries, Ltd., and 50 parts by weight of "EHPE3150CE" (trade name) manufactured by Daicel Chemical Industries, Ltd. were used.

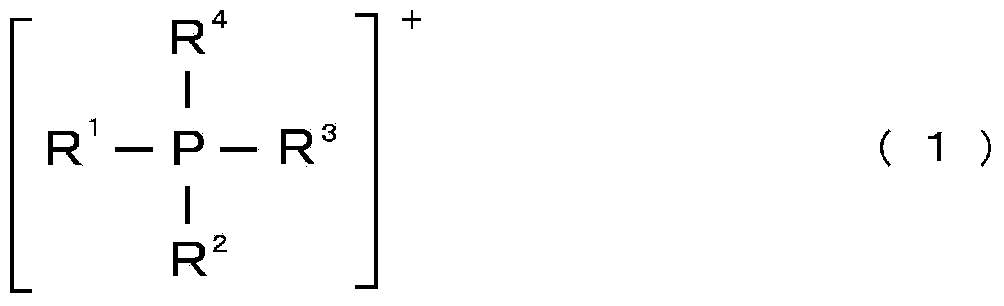

[0106] As a curing agent, 100 parts by weight of methylhexahydrophthalic anhydride (manufactured by Shinnippon Chemical Co., Ltd., trade name "Rikacid MH-700") was used, and as a curing accelerator, tetraphenyl bromide (manufactured by Wako Pure Chemical Industries, Ltd.) 1 part by weight. In addition, 1.5 parts by weight of ethylene glycol (manufactured by Wako Pure Chemical Industries, Ltd.) was used.

[0107] The above-mentioned components were uniformly mixed (2000 rpm, 5 minutes) using "a defoaming stirrer" manufactured by Thinky Co., Ltd., to obtain a resin composition for encapsulating an optical semiconductor.

Embodiment 2

[0109] In addition to the use of ethyl triphenyl iodide (Wako Pure Chemical Industries Co., Ltd.) 0.5 parts by weight and triphenylphosphine (Kishida Chemical Co., Ltd.) 0.5 parts by weight were used as curing accelerators, and a resin combination for optical semiconductor sealing was obtained in the same manner as in Example 1. things.

Embodiment 3

[0111] As the epoxy resin, 70 parts by weight of "EHPE3150CE" (trade name) manufactured by Daicel Chemical Industry Co., Ltd. and 30 parts by weight of "YD-128" (trade name) manufactured by Tohto Chemical Co., Ltd. were used, except In addition, the resin composition for optical semiconductor sealing was obtained by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com