LED ceramic baseplate and preparation method thereof

A technology of ceramic substrate and organic solvent, applied in the field of high thermal conductivity, high reflection ceramic substrate and its preparation, can solve the problem of not considering optical requirements and the like, and achieve the effects of simple preparation method, prolonged service life and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

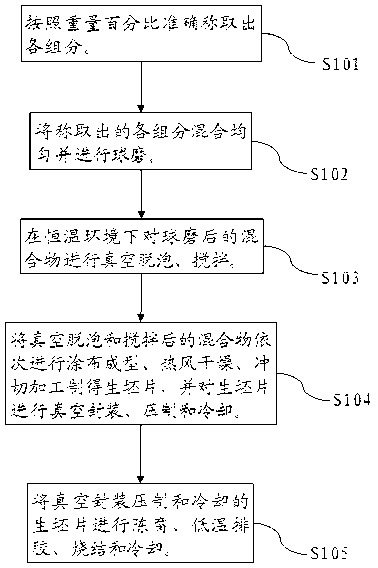

[0046] A preparation method based on the aforementioned LED ceramic substrate described in the embodiment of the present invention includes the following steps:

[0047] Step S101. Accurately weigh and take out each component according to the weight percentage;

[0048] Step S102. Mix the weighed components uniformly and perform ball milling;

[0049] Step S103. Vacuum defoaming and stirring the ball-milled mixture in a constant temperature environment;

[0050] Step S104. The mixture after vacuum defoaming and stirring is sequentially subjected to coating molding, hot air drying, and punching to obtain a green sheet, and vacuum packaging, pressing and cooling the green sheet;

[0051] Step S105. The vacuum-encapsulated pressed and cooled green sheet is subjected to staling, low-temperature debinding, sintering and cooling.

[0052] Wherein, the said components that are weighed out are mixed uniformly and ball milled, which may specifically be: firstly, alumina, oxidation ad...

Embodiment 1

[0063] A LED ceramic substrate described in the embodiment of the present invention is made of the following components and their weight percentages: 60% aluminum oxide, 0.5% rare earth oxide, 30% organic solvent, 1.2% surfactant, and 3% adhesive , 2.5% plasticizer and 2.8% oxide additive; during preparation, according to the components and weight percentages and through the preparation method of the present invention, high heat dissipation, high surface finish, low roughness, and enhanced The reflectivity of light improves the light efficiency, reduces light decay, and prolongs the service life of LED lamps. Ceramic substrates for LED packaging.

Embodiment 2

[0065] An LED ceramic substrate described in the embodiment of the present invention is made of the following components and their weight percentages: 65% aluminum oxide, 0.4% rare earth oxide, 20% organic solvent, 0.8% surfactant, and 4.5% adhesive , 5.3% plasticizer and 4% oxide additive; during preparation, according to the composition and weight percentage and through the preparation method of the present invention, high heat dissipation, high surface finish, low roughness, and enhanced The reflectivity of light improves the light efficiency, reduces light decay, and prolongs the service life of LED lamps. Ceramic substrates for LED packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com