Method for simultaneously extracting and separating solanesol and nicotine from tobacco

A technology for solanesol and nicotine, which is applied in the field of simultaneous extraction and separation of solanesol and nicotine, can solve the problems of large amount of waste water, single extraction type, low product purity, etc., and achieves less waste liquid discharge and more extraction products. , the effect of simplifying the extraction step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

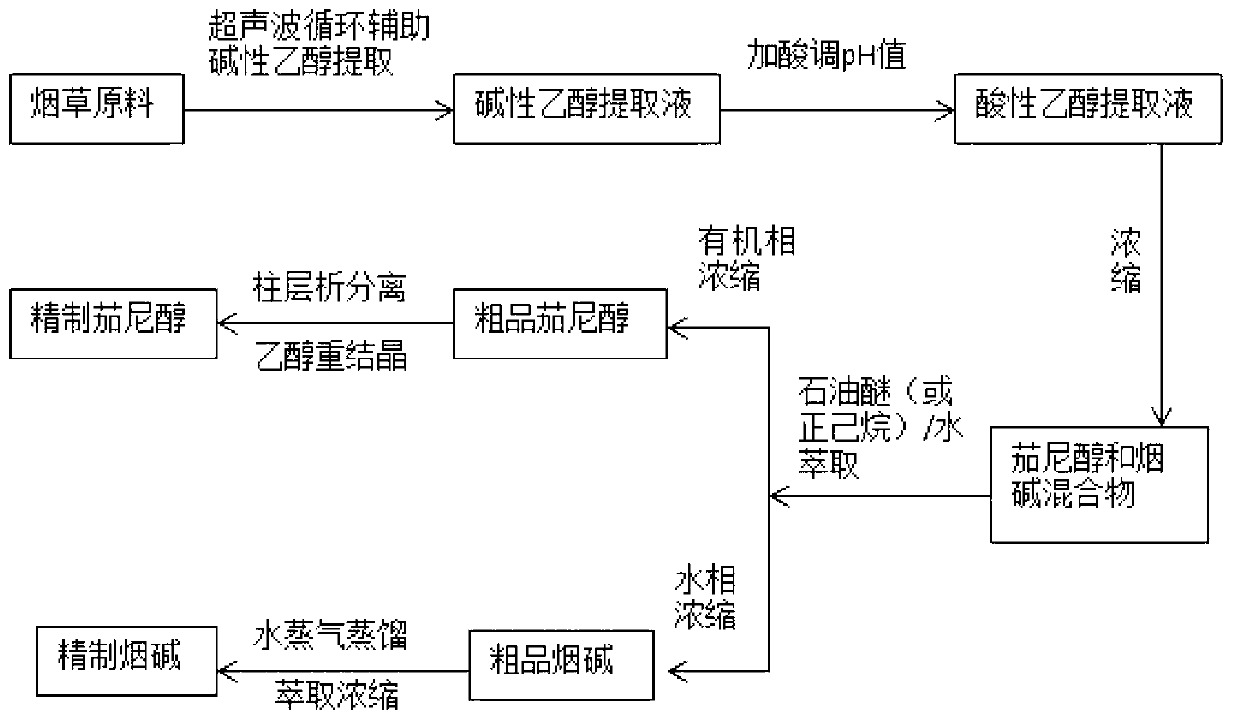

[0037] (1) Simultaneous extraction of solanesol and nicotine: After 50g of tobacco raw material is dried and pulverized (about 20 mesh), it is added to a circulating ultrasonic extractor, and then 500g of 0.1mol / L NaOH ethanol solution is added, and the ultrasonic power is 100W. Under the condition of temperature 50°C, ultrasonic circulation extraction was carried out for 30 minutes.

[0038] (2) Extraction and separation: After the ultrasonic extraction is completed, the ethanol extract is released, and the tobacco filter residue is removed by filtration. The filtrate is adjusted to pH 2 by hydrochloric acid solution, and then the ethanol is removed by vacuum concentration to obtain a crude solanesol nicotine mixture. The crude product mixture was separated by liquid-liquid two-phase extraction with 300 mL petroleum ether / 300 mL water. The product enriched in the petroleum ether layer is crude solanesol, and the product enriched in the water layer is crude nicotine.

[0039]...

Embodiment 2

[0042](1) Simultaneous extraction of solanesol and nicotine: After 100g of tobacco raw material is dried and pulverized (about 20 mesh), it is added to a circular ultrasonic extractor, and then 1200g of 0.1mol / L NaOH ethanol solution is added, and the ultrasonic power is 200W. Under the condition of temperature 60°C, ultrasonic circulation extraction was carried out for 50 minutes.

[0043] (2) Extraction and separation: After the ultrasonic extraction is completed, the ethanol extract is released, and the tobacco filter residue is removed by filtration. The filtrate is adjusted to pH 3 by hydrochloric acid solution, and then the ethanol is removed by vacuum concentration to obtain a crude solanesol nicotine mixture. The crude product mixture was separated by liquid-liquid two-phase extraction with 500 mL petroleum ether / 500 mL water. The product enriched in the petroleum ether layer is crude solanesol, and the product enriched in the water layer is crude nicotine.

[0044] (...

Embodiment 3

[0047] (1) Simultaneous extraction of solanesol and nicotine: After 100g of tobacco raw material is dried and pulverized (about 20 mesh), it is added to a circulating ultrasonic extractor, and then 1500g of 0.1mol / L NaOH ethanol solution is added, and the ultrasonic power is 300W. Under the condition of temperature 60°C, ultrasonic circulation extraction was carried out for 60 min.

[0048] (2) Extraction and separation: After the ultrasonic extraction is completed, the ethanol extract is released, and the tobacco filter residue is removed by filtration. The filtrate is adjusted to pH 4 by hydrochloric acid solution, and then the ethanol is removed by vacuum concentration to obtain a crude solanesol nicotine mixture. The crude product mixture was separated by liquid-liquid two-phase extraction with 500 mL petroleum ether / 500 mL water. The product enriched in the petroleum ether layer is crude solanesol, and the product enriched in the water layer is crude nicotine.

[0049] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com