Safety blocking remover for oilfield fractured well

An oilfield fracturing and plugging removal agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as unsafe oilfields, hidden dangers, and poor results, and achieve small equipment damage, thorough plugging removal, and Improve water quality and prevent blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

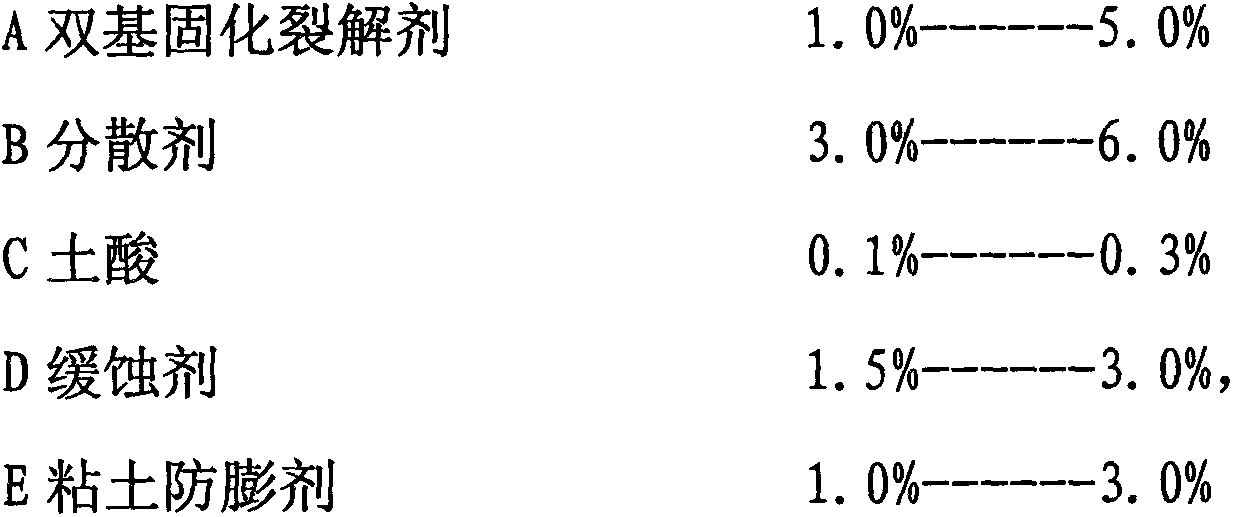

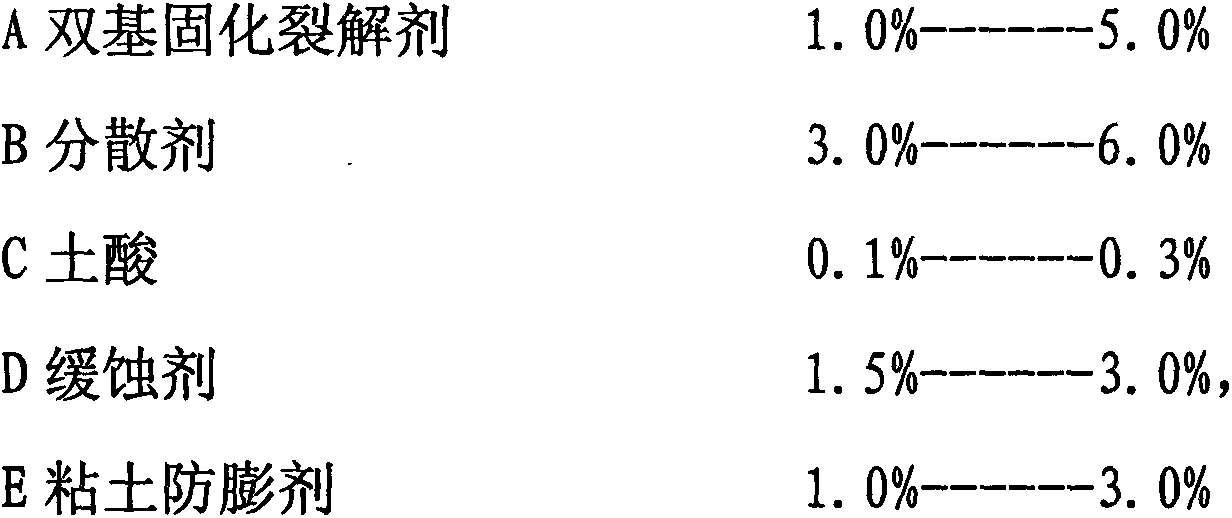

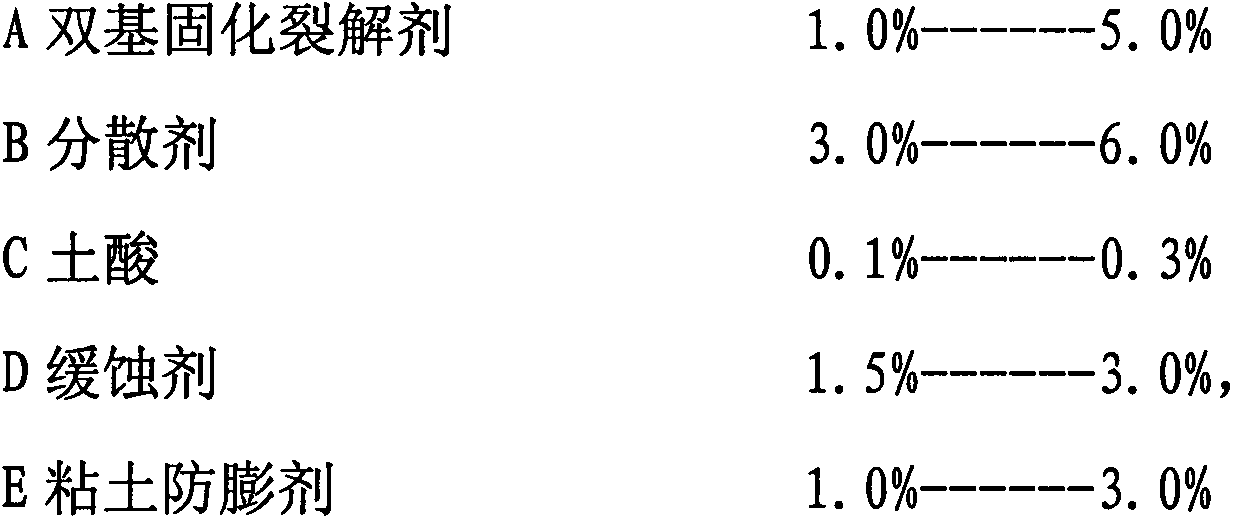

[0007] Oil field fracturing well safety plugging remover, composed of the following components in volume percentage:

[0008]

[0009] Wherein the double base curing cracking agent is compounded by H chemical substances and complexes, said H chemical substances refer to chemical substances that can generate oxygen free radicals after decomposition, and said H chemical substances Contains Calcium Peroxide, Potassium Persulfate, Complexes Contains Diphenylthiourea, EDTA. The double-base curing cracking agent is a synthetic product of at least one of the above-mentioned H chemicals and at least one of the above-mentioned complexes. The dispersant is triethylhexyl phosphoric acid, methyl amyl alcohol, one of polyacrylamide, the earth acid is a mixed acid of hydrofluoric acid and hydrochloric acid, and the corrosion inhibitor is composed of quinoline, Halogenated hydrocarbon, dehydrated alcohol, alkyl polyoxyethylene ether with a molecular weight of 826, hydrochloric acid and m...

Embodiment 2

[0011] Oil field fracturing well safety plugging remover, composed of 1.0% double-base solidification cracking agent, 3.0% dispersant, 0.1% earth acid, 1.5% corrosion inhibitor, 1.0% clay anti-swelling agent, and other components are water:

[0012] Wherein the double-base curing cracking agent is compounded by H chemical substances and complexes, the H chemical substances are calcium peroxide, and the complexes are diphenylthiourea. The double-base curing cracking agent is a synthetic product of calcium peroxide and diphenylthiourea. The dispersant is triethylhexyl phosphoric acid, the earth acid is a mixed acid of hydrofluoric acid and hydrochloric acid, and the corrosion inhibitor is composed of quinoline, halogenated hydrocarbon, dehydrated alcohol, and an alkane with a molecular weight of 826. The product synthesized by base polyoxyethylene ether, hydrochloric acid and methanol, and the clay stabilizer is potassium chloride solution. Earth acid is a mixed acid of hydrofl...

Embodiment 3

[0014] Oil field fracturing well safety plugging remover, composed of 3.0% double-base curing cracking agent, 4.5% dispersant, 0.2% earth acid, 2.25% corrosion inhibitor, 2.0% clay anti-swelling agent, and other components are water:

[0015] Wherein the double base curing cracking agent is compounded by H chemical substances and complexes, the H chemical substances are potassium persulfate, and the complexes are ethylenediaminetetraacetic acid. The double-base curing cracking agent is a synthetic product of potassium persulfate and ethylenediaminetetraacetic acid. The dispersant is methyl amyl alcohol, the earth acid is a mixed acid of hydrofluoric acid and hydrochloric acid, and the corrosion inhibitor is made of quinoline, halogenated hydrocarbon, dehydrated alcohol, and an alkyl group with a molecular weight of 826. Polyoxyethylene ether, hydrochloric acid and methanol synthesis product, described clay stabilizer is potassium chloride solution. Earth acid is a mixed acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com