A kind of high-strength magnesium-aluminum-manganese-strontium alloy and its preparation method

A high-strength, alloy technology, which is applied in the field of high-strength magnesium-aluminum-manganese-strontium magnesium alloys and their preparation, can solve the problems of expensive Zr elements, which cannot meet industrial applications, and limit widespread use, and achieve low prices, Low cost, effect of suppressing grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

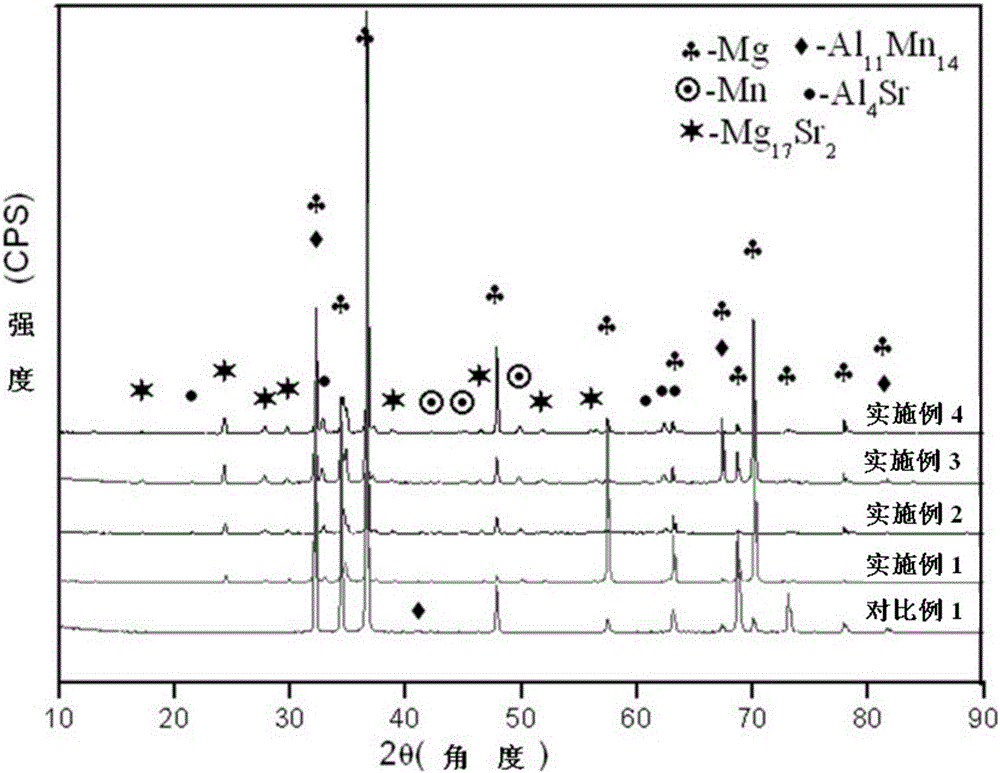

Examples

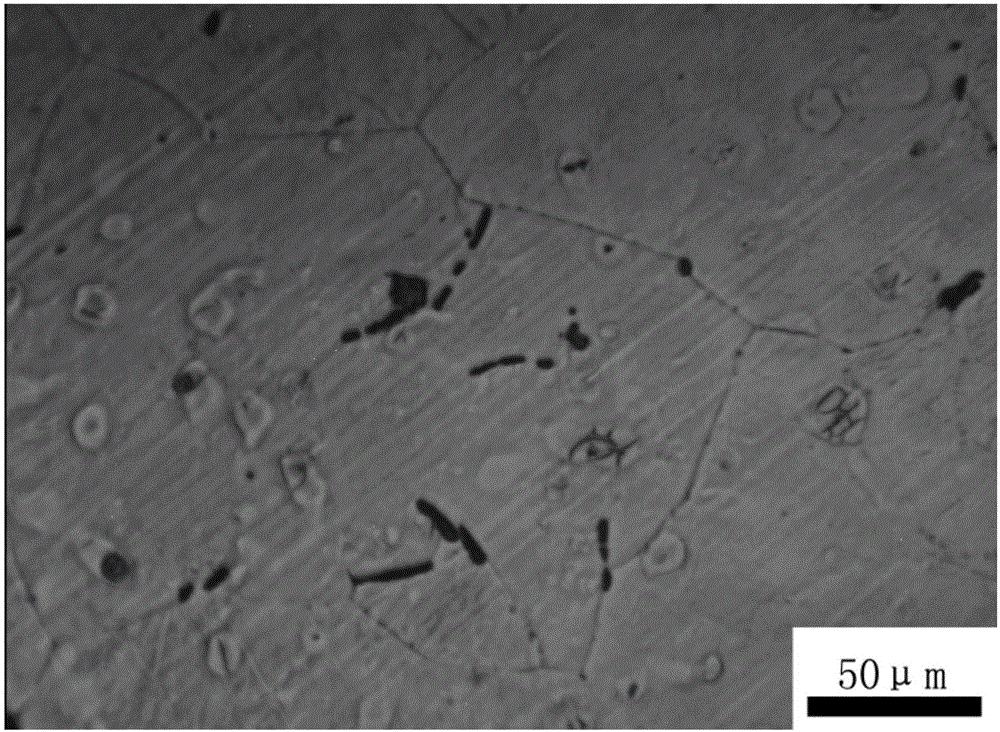

Embodiment 1

[0041] The method for preparing high-strength magnesium-aluminum-manganese-strontium alloy in this embodiment comprises the following steps:

[0042] 1) smelting: at first select raw material according to the formula of table 1 embodiment 1, wherein raw material is industrial pure magnesium ingot, industrial pure aluminum, Mg-5%Mn master alloy and Mg-5%Sr master alloy; Then raw material is put into filling Melt in a vacuum induction furnace with argon, stir for 2-5 minutes after all melted to make the ingredients uniform; finally close the induction furnace, take out the crucible and cool it with water cooling.

[0043] 2) Machining: turning to remove the oxide layer on the surface of the alloy obtained in step 1), and making the size of the processed magnesium alloy suitable for extrusion processing;

[0044] 3) Homogenization treatment: heat the alloy obtained in step 2) to 420°C with the furnace, and keep at this temperature for 10 hours for homogenization annealing;

[00...

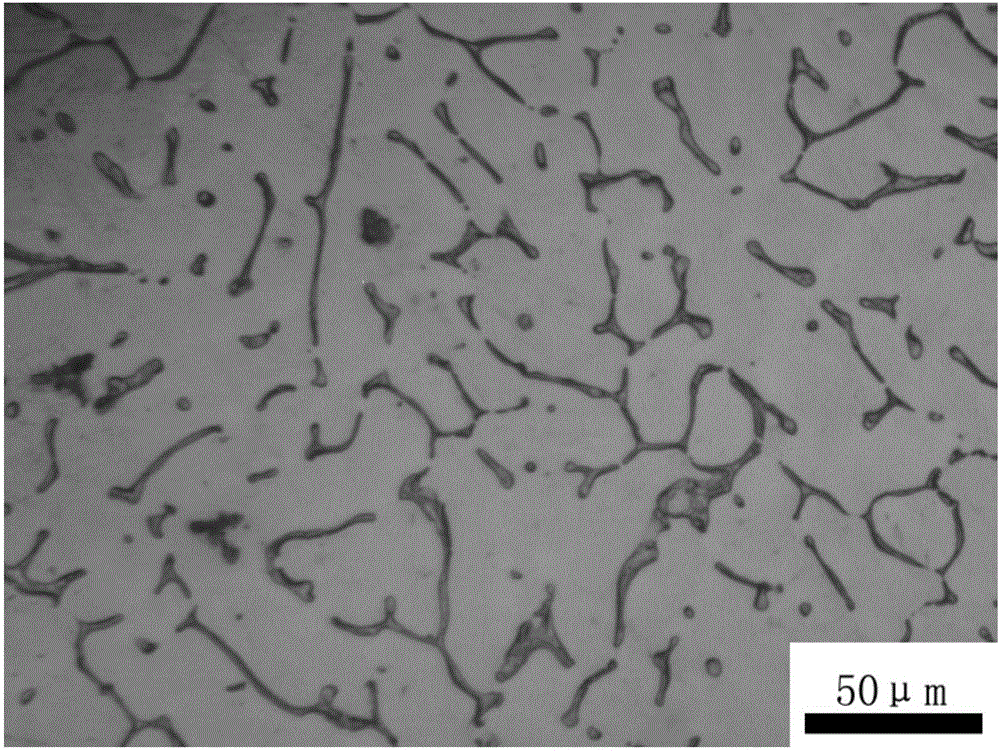

Embodiment 2

[0047] The difference between this example and Example 1 is that this example selects raw materials according to the formula of Example 2 in Table 1.

Embodiment 3

[0049] The difference between this example and Example 1 is that this example selects raw materials according to the formula of Example 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com