Supporting and construction method of steel sheet pile under soft foundation of high flow plastic deep layer

A construction method, steel sheet pile technology, applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of difficult disassembly and reuse, uneconomical construction, and large amount of consumables, so as to prevent piping and make the construction process simple and easy , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

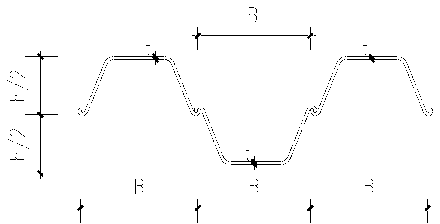

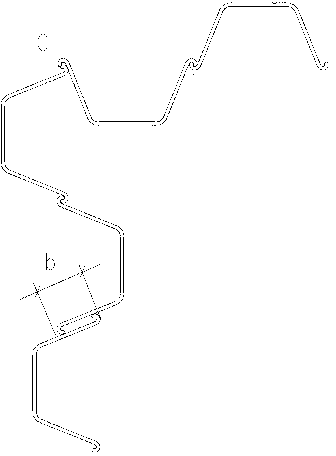

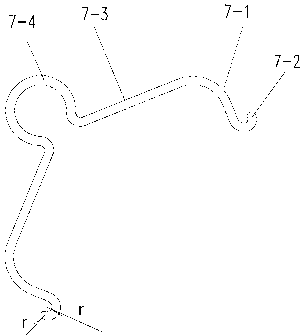

[0031] The steel sheet pile support construction under the deep soft foundation in this embodiment goes through the following steps (mainly refer to Figure 4 ):

[0032] The first step, construction preparation - build drainage ditches 1 around the foundation pit, and arrange drainage wells at the four corners of the pit to pump out the groundwater; evenly coat the locks of the steel sheet piles with mixed oil, and the volume ratio of the mixed oil is butter: dry bentonite: Dry saw foam = 5:4-6:2-4, this kind of mixed oil has low cost and good waterproof and sealing effect; if necessary, the surface of the steel sheet pile is painted with anti-corrosion paint, and the lock of the steel sheet pile is coated with a water-stop sealant to ensure anti-corrosion , Sealing effect.

[0033] The second step is to build the guide purlin——weld the rectangular guide purlin 3 of the frame structure according to the inner profile of the foundation pit, and after forming a circle, fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com