Device and method for exhaust steam waste heat recovery and pollution abatement in aluminum oxide production

A waste heat recovery and alumina technology, which is applied in cleaning heat transfer devices, alumina/aluminum hydroxide, chemical industry, etc., can solve problems such as affecting waste heat recovery and utilization efficiency, scaling of waste heat recovery devices, and scrapping of waste heat recovery devices. , to achieve the effect of light weight, saving floor space and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

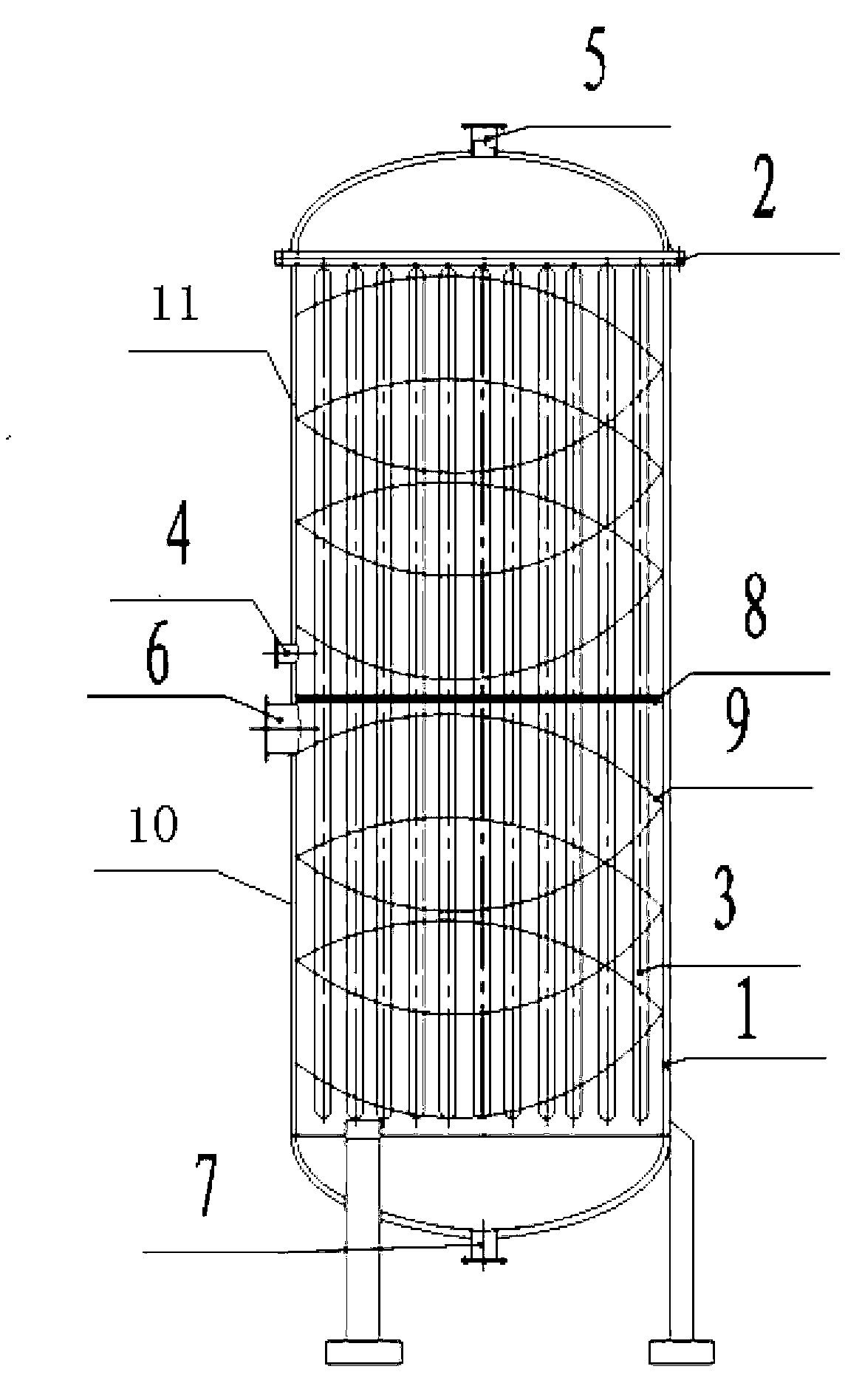

[0051] The present invention will be further described below in conjunction with the accompanying drawings and the example of red mud water in the alumina production process heated by waste heat of high-temperature steam evacuated during high-pressure leaching of recovered alumina.

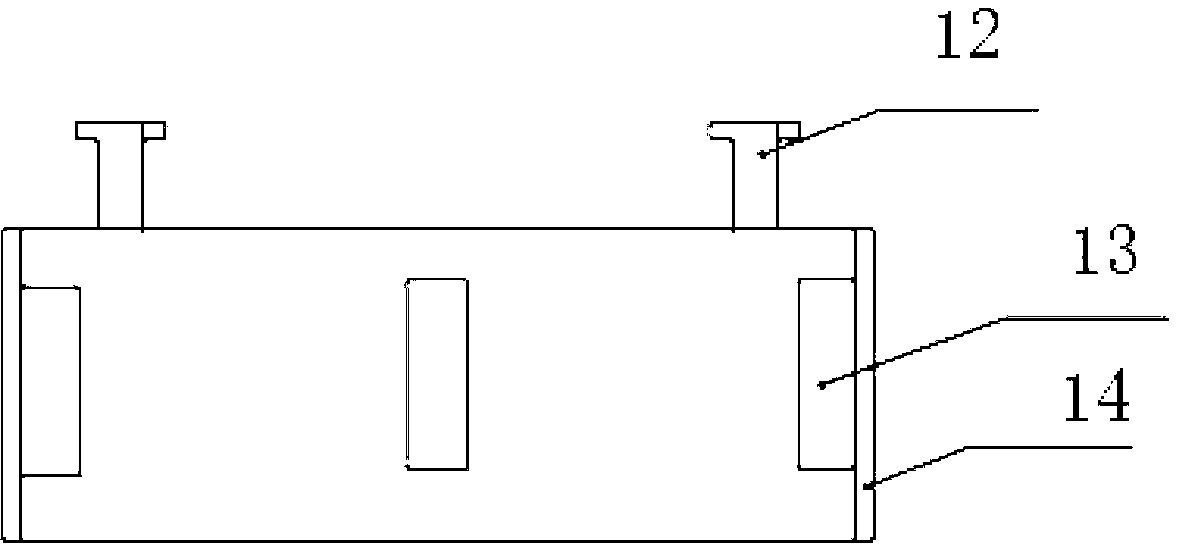

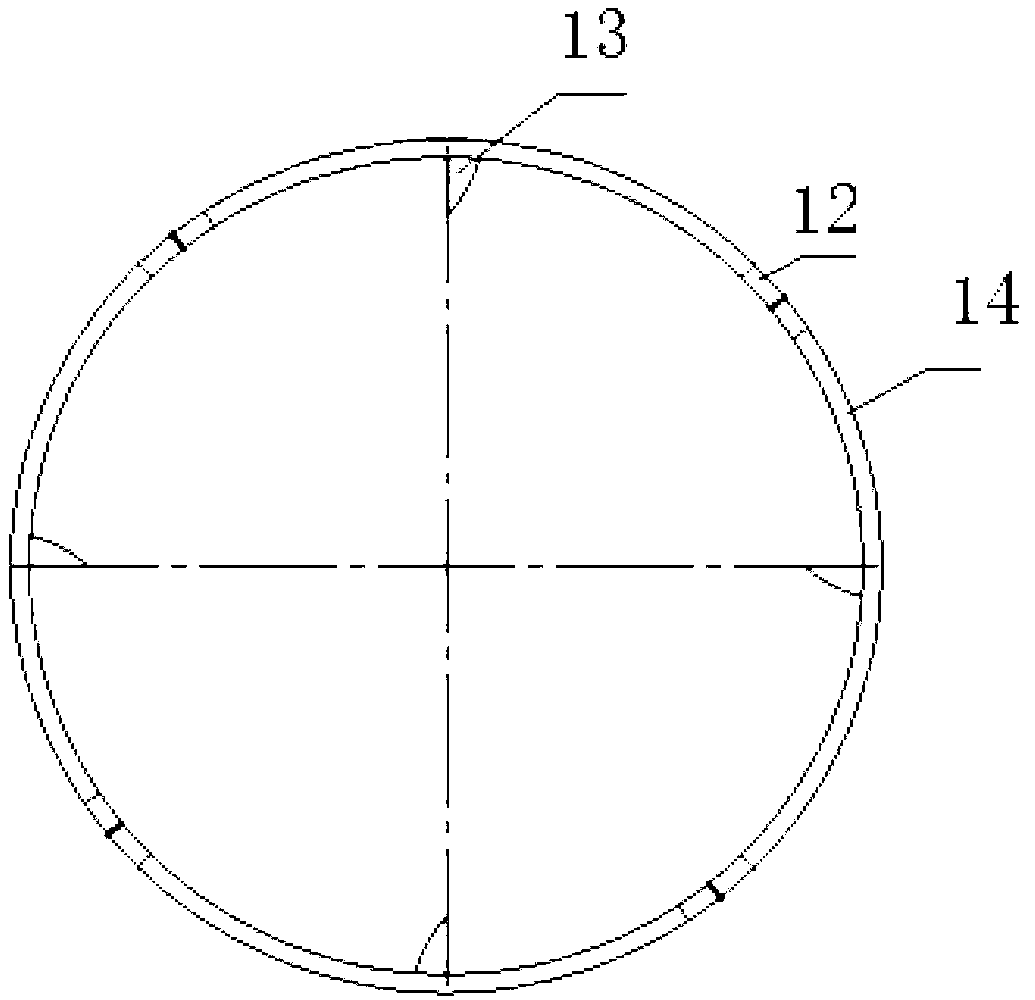

[0052] Such as Figure 1-Figure 4As shown, the present invention includes a metal cylinder 1, the metal cylinder 1 is separated by a metal partition 8 in the middle, the low temperature medium chamber 11 is above the partition 8, and the high temperature medium chamber 10 is below the partition 8, and The low-temperature medium chamber 11 and the high-temperature medium chamber 10 are provided with heat pipes 3 penetrating through the partition 8, and each of the heat pipes 3 works independently.

[0053] A water inlet 4 is provided on the outer wall of the low-temperature medium chamber 11 , and an air inlet 6 is provided on the outer wall of the high-temperature medium chamber 10 .

[0054] A w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com