Humidity optimization control method for waste heat drying system

A drying system and optimized control technology, applied in the information field, can solve problems such as poor drying effect, waste of gas, and inconformity with energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

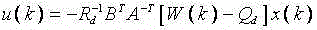

[0069] Humidity optimization control method of waste heat drying system, in the early stage of drying, the combination of feedforward-feedback control method and model predictive control method (MAC, model algorithm control) is used to control the valve opening of gas two-way valve and cold distribution air two-way valve and feed flow control. The specific implementation method is as follows:

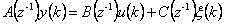

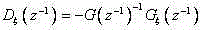

[0070] 1) Determine the prediction model The value of each parameter matrix in

[0071] The least squares identification method of the multi-input-multi-output system is used to identify the system parameters, and the system parameters are

[0072] , ,

[0073] in , , is the number of sampling points, , , The estimated value of can be given by the formula An unbiased estimate of is obtained, where the measured parameter matrix and a matrix of measured output values The specific calculation is as follows

[0074]

[0075]

[0076] in is the sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com