TSV wafer reverse side thinning control method and system based on vortex technology

A backside thinning and control method technology, applied in the field of microelectronics, can solve the inability to accurately obtain the distance from the bottom of the conductive metal pillar to the back of the wafer, the influence of etching and other processes, the depth of the hole and the depth of the deposition of the conductive metal pillar error and other problems, to achieve the effect of convenient installation, small measurement error and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

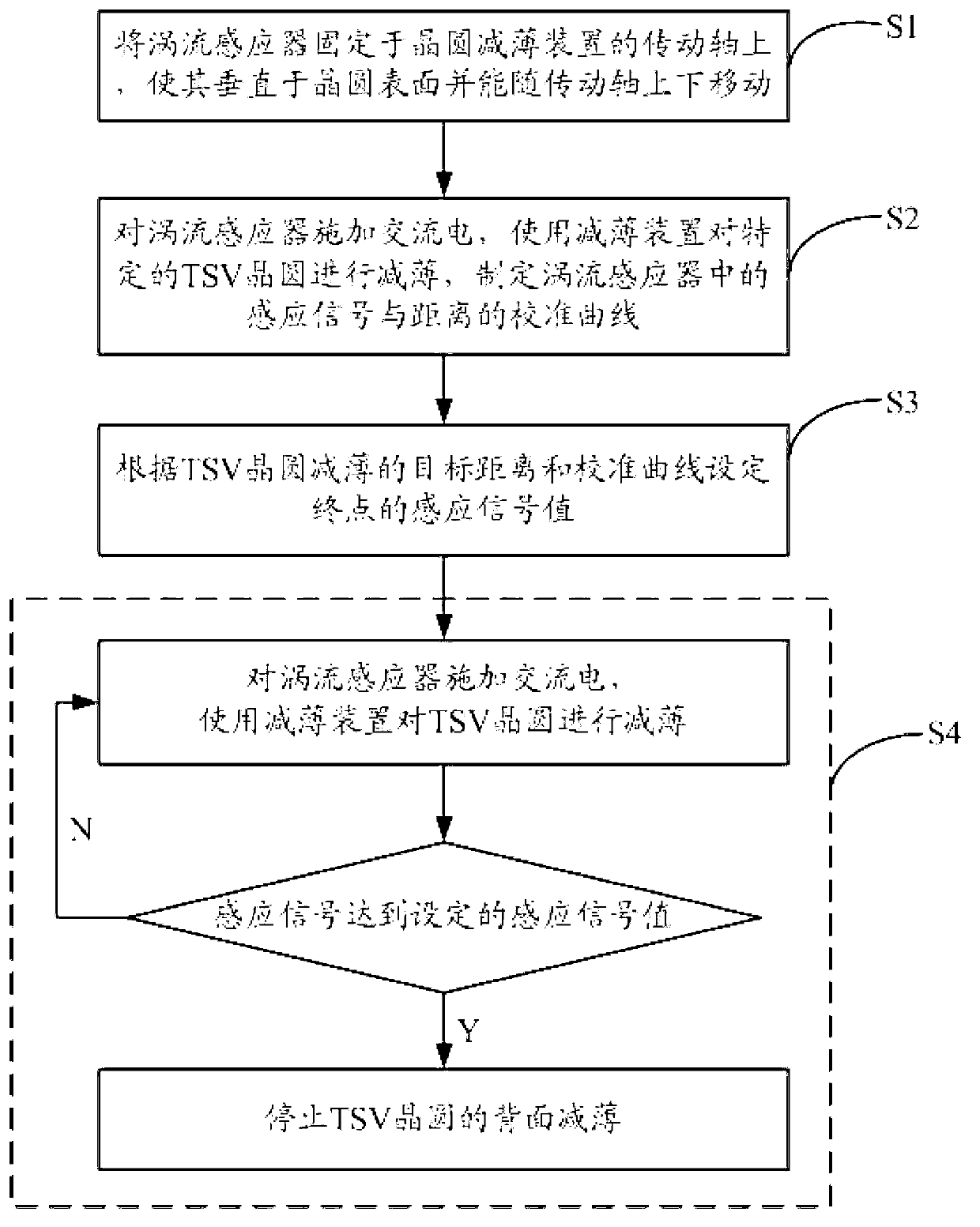

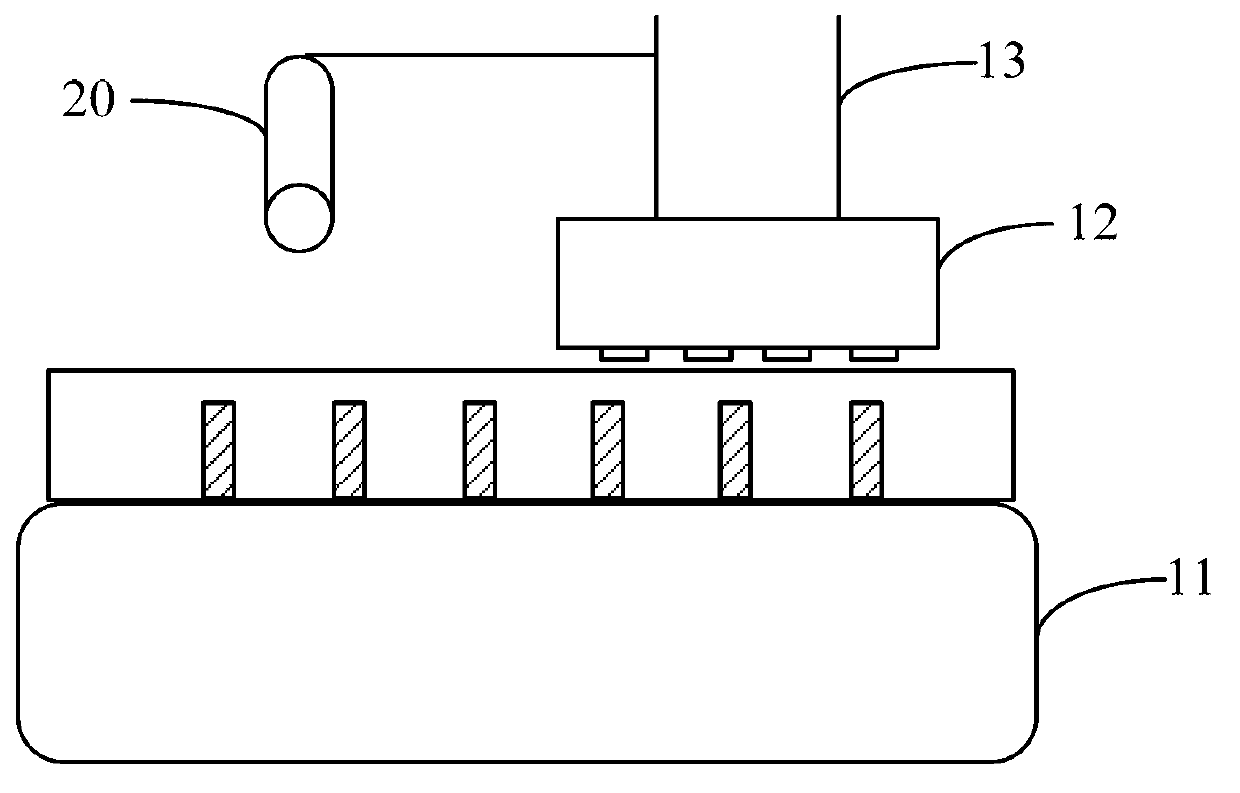

[0033] Such as figure 1 As shown, the TSV wafer backside thinning control method based on eddy current technology in a preferred embodiment of the present invention comprises the following steps:

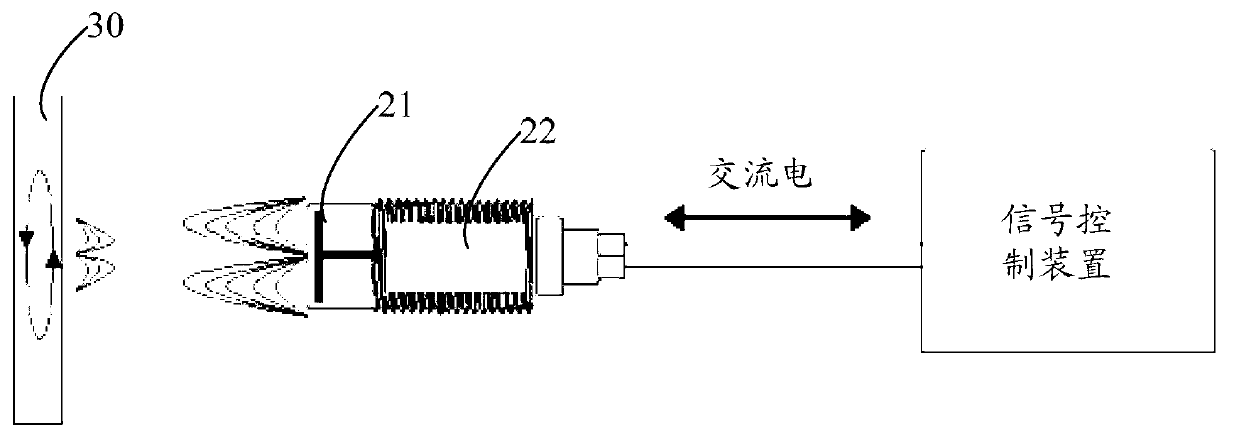

[0034] S1. Fix the eddy current sensor on the transmission shaft of the wafer thinning device, so that the eddy current sensor is perpendicular to the wafer surface and can move up and down with the transmission shaft;

[0035] S2. Apply alternating current to the eddy current sensor, use a thinning device to thin a specific TSV wafer, and formulate a calibration curve of the induction signal and distance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com