Gallium nitride based light emitting diode chip and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the decline of luminous efficiency of LED chips, and achieve the effect of solving the decline of luminous efficiency, reducing the number of cycles, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Step 1, Substrate Formation and Handling

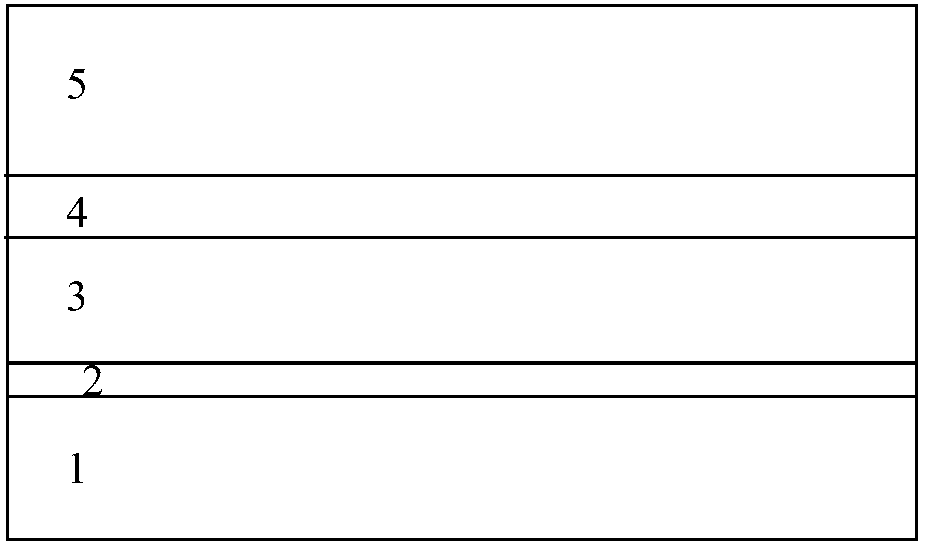

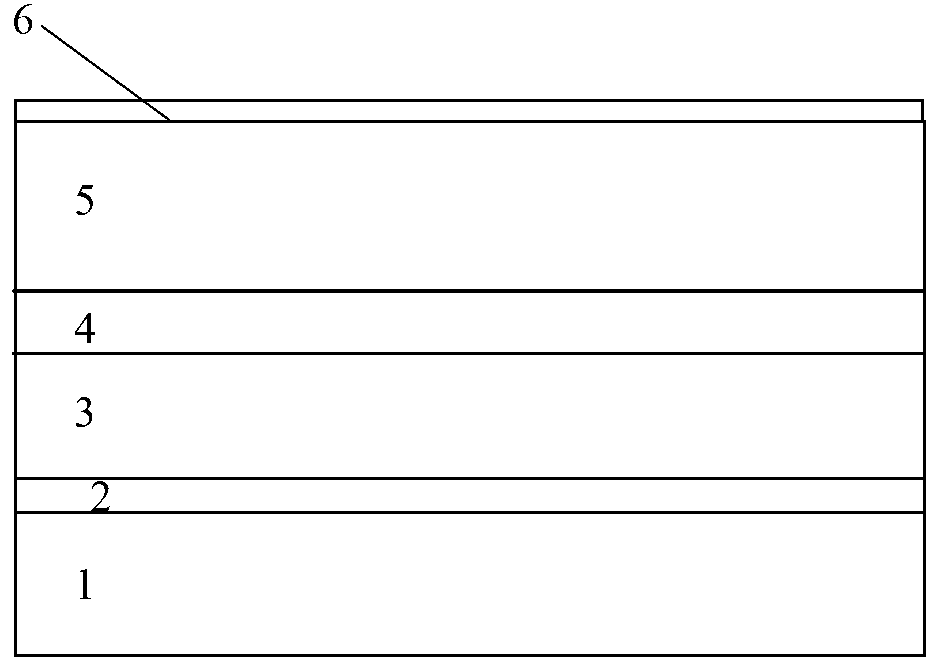

[0051] The epitaxial wafer with LED epitaxial structure grown by MOCVD on a 2-inch sapphire substrate is used as the substrate. The composition of the substrate from bottom to top is: sapphire substrate 1, GaN buffer layer 2, Si-doped n-GaN Layer 3, InGaN / GaN multi-quantum well active region 4 and Mg-doped p-type GaN layer 5, the above substrate was heated at 700°C 2 In a rapid annealing furnace in an ambient atmosphere, a heat treatment process is performed for 60 s to activate the Mg in the Mg-doped p-type GaN layer 5. The substrate obtained by this treatment is soaked in acetone and isopropanol in sequence and then rinsed with deionized water. to remove surface organic contaminants, and then put it into HCl:H 2 Soak in the solution of O=1:5 for 5 minutes, then flush with deionized water for 5 minutes, heat at 80°C in N 2 Dry for 10 minutes until the metal ions attached to the surface are removed;

[0052] The second step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com