MEMS vibration energy collector based on PZT piezoelectric beam array

A technology of vibration energy collection and piezoelectric beams, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve large rectification loss, low output voltage, difficult Load power supply and other issues, to achieve the effect of reducing air damping, high output voltage, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

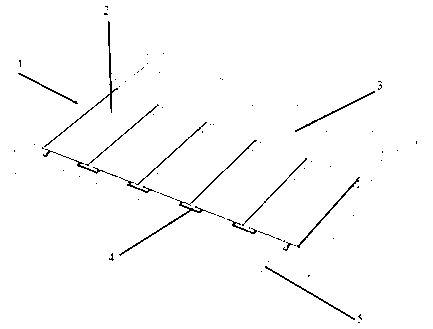

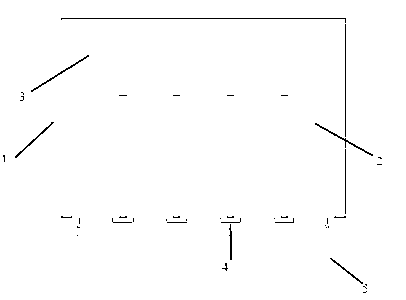

[0029] see figure 1 and figure 2 The MEMS vibration energy harvester based on the PZT piezoelectric beam array proposed by the present invention is composed of a plurality of PZT piezoelectric beams 2 , a quality block 3 and a silicon-based outer frame 1 . One end of these piezoelectric beams 2 is fixed on the silicon-based outer frame 1 and arranged in a row along the width direction to form an array, and there is a certain gap between each beam to form an array. The other ends of these PZT piezoelectric beams 2 share a mass block 3 . The PZT piezoelectric cantilever beams 2 are connected in series through metal wires 4 , and the current is output by connecting wires 5 at two welding points.

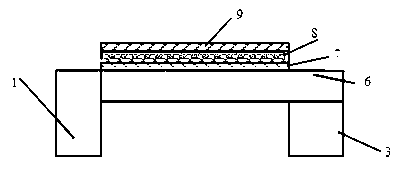

[0030] see Figure 4 , PZT piezoelectric beams are made of silicon substrate 6, SiO 2 Buried layer 10, Ti / Pt electrode 7, LNO layer 11, Al electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com