No-tillage water-saving cotton seeding method

A cotton and pre-sowing technology, applied in the field of cotton no-tillage and water-saving sowing, can solve the problems of cotton seeds not emerging normally, low water use efficiency, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 No-tillage water-saving cotton sowing method

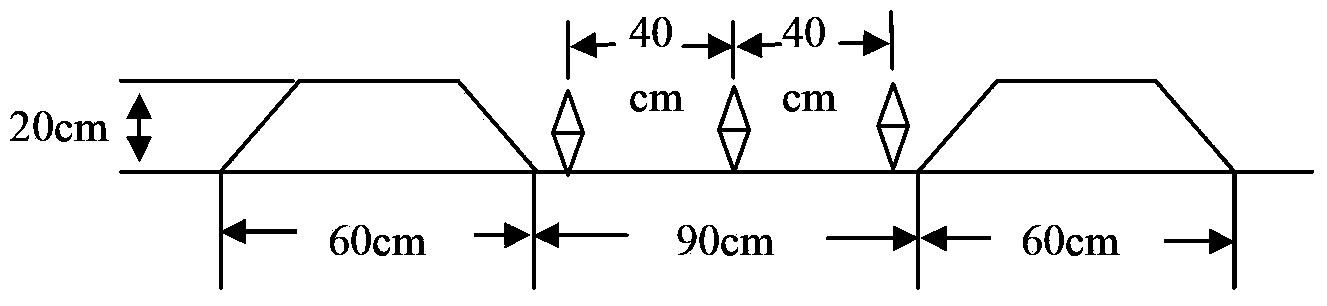

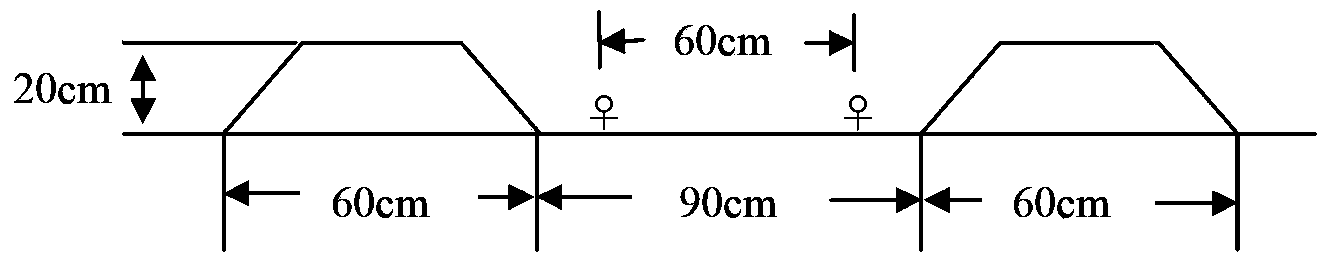

[0022] 1. Selection and arrangement of plots. On April 3, 2011, in Dongwei Village, Cheng'an Town, Cheng'an County, Hebei Province, a plot of 30 mu with flat terrain was selected. After simply leveling the plot, use a tractor to ridge and fertilize under the ridge. The fertilization under the ridge is carried out according to the row spacing of 40cm, a total of 3 rows, the ridge width is 60cm, and the ridge spacing is 90cm. The mechanical cost is about 60 yuan / mu, which is 120 yuan / mu less than the common sowing method.

[0023] 2. Watering. On April 11, 2011, the pumped well was used to pump groundwater for irrigation, and the water was irrigated under the ridge. The total pumped water was about 1,000 tons, which saved more than 50% of water compared with flood irrigation.

[0024] 3. Spraying herbicides and laying mulch. When the water under the ridge seeps into the ground and there is no clear water, use...

Embodiment 2

[0028] Influence of substrate on emergence rate under the condition of no-tillage and water-saving sowing of embodiment 2

[0029] In 2010, a test of the impact of substrate dosage on the emergence rate was carried out at the Cotton Research Institute of the Chinese Academy of Agricultural Sciences in 2010. The no-tillage and water-saving seeding method provided by the present invention was used to set up 2 factors and 4 levels of random block experiments, 2 row blocks 3 repetitions, Residential Area 20m 2 ,The diameter of the sowing hole is 2.5CM, and the sowing depth is 2, 2.5, 3, and 4cm. , 2.5 times four levels, the standard is that the upper surface of the substrate is flush with the surrounding plastic film, and the cotyledon is flat (every 8 days after sowing) to investigate the emergence rate. The test results are as follows:

[0030]

2cm

2.5cm

3cm

4cm

1 times

82.1

83.4

83.1

85.4

1.5 times

88.6

98.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com