Preparation method of antibacterial powders for antibacterial coating

The technology of antibacterial paint and antibacterial powder is applied in the field of preparation of antibacterial powder, which can solve the problems of short time and poor antibacterial effect of antibacterial paint, and achieve the effect of long antibacterial time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

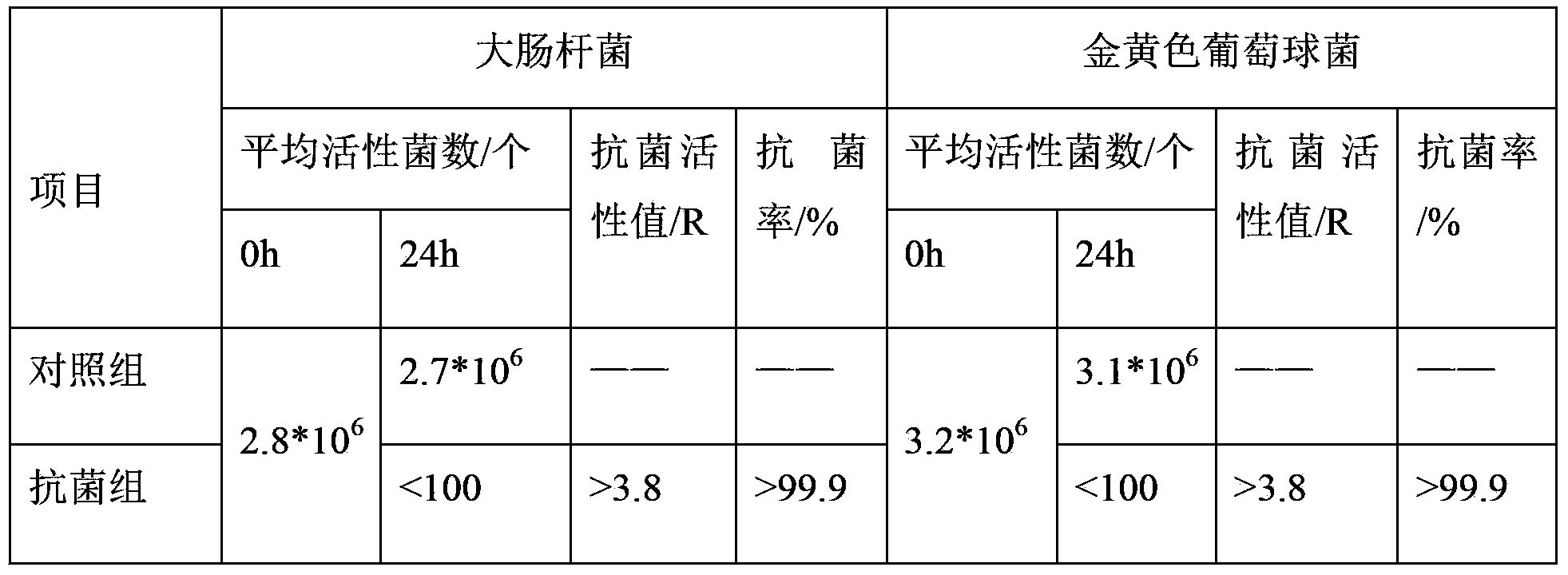

Examples

Embodiment 1

[0017] An antibacterial powder for antibacterial coatings, the components of which are prepared by parts by weight from the following components: 45 parts of a silver nitrate solution with a mass concentration of 70%, 15 parts of a copper nitrate solution with a mass concentration of 70%, and a mass concentration of 70% 15 parts of zinc nitrate solution, 8 parts of triethyl tin chloride, Na 3 PO 4 40 parts of gelatin solution.

[0018] Above-mentioned antibacterial powder, its preparation process comprises the following steps:

[0019] (1) Weighing: Weigh the above-mentioned raw materials in parts by weight:

[0020] (2) Na 3 PO 4 Pour the gelatin solution into the reaction kettle, then drop the silver nitrate solution, copper nitrate solution, and zinc nitrate solution into the reaction kettle, finish the dripping within 30 minutes, adjust the pH value between 6 and 7, and then add triethyl chloride Stir the tin to obtain a colloid;

[0021] (3) Sedimentation filtration...

Embodiment 2

[0027] An antibacterial powder for antibacterial coatings, the components of which are prepared by parts by weight from the following components: 40 parts of silver nitrate solution with a mass concentration of 70%, 25 parts of a copper nitrate solution with a mass concentration of 70%, and a mass concentration of 70% 25 parts of zinc nitrate solution, 8 parts of triethyl tin chloride, Na 3 PO 4 55 parts of gelatin solution.

[0028] Above-mentioned a kind of antibacterial powder that is used for antibacterial coating, its preparation process comprises the following steps:

[0029] (1) Weighing: Weigh the above-mentioned raw materials in parts by weight:

[0030] (2) Na 3 PO 4 Pour the gelatin solution into the reaction kettle, then drop the silver nitrate solution, copper nitrate solution, and zinc nitrate solution into the reaction kettle, finish the dripping within 30 minutes, adjust the pH value between 6 and 7, and then add triethyl chloride Stir the tin to obtain a ...

Embodiment 3

[0037] An antibacterial powder for antibacterial coatings, the components of which are prepared by parts by weight from the following components: 42 parts of a silver nitrate solution with a mass concentration of 70%, 18 parts of a copper nitrate solution with a mass concentration of 70%, and a mass concentration of 70% 18 parts of zinc nitrate solution, 11 parts of triethyl tin chloride, Na 3 PO 4 50 parts of gelatin solution.

[0038] Above-mentioned a kind of antibacterial powder that is used for antibacterial coating, its preparation process comprises the following steps:

[0039] (1) Weighing: Weigh the above-mentioned raw materials in parts by weight:

[0040] (2) Na 3 PO 4 Pour the gelatin solution into the reaction kettle, then drop the silver nitrate solution, copper nitrate solution, and zinc nitrate solution into the reaction kettle, finish the dripping within 30 minutes, adjust the pH value between 6 and 7, and then add triethyl chloride Stir the tin to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com