Preparation method of soft white mould cheese

A technology for soft cheese and white mold is applied in the field of preparation of soft cheese with white mold, which can solve the problems such as non-conformity and achieve the effects of fine texture, good flavor and shortening of maturation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

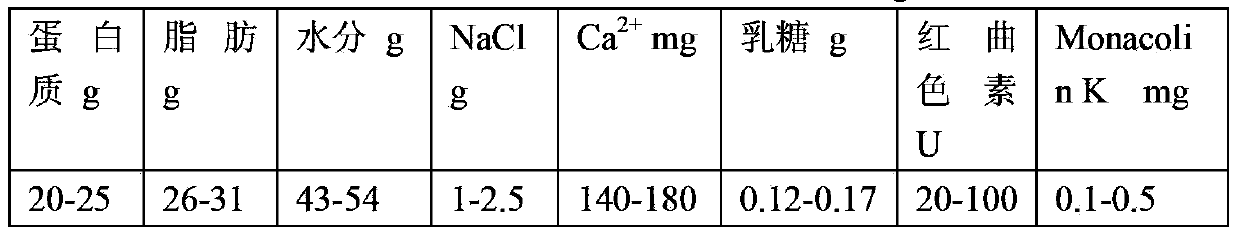

[0020] Standardization: The raw milk that has passed the inspection is standardized so that the ratio of protein to fat is 0.8 (w / w) to obtain raw milk;

[0021] Pasteurization: The sterilization condition is 72°C for 15s.

[0022] Acidification fermentation: Cool the pasteurized raw milk and keep the temperature of the milk at 32°C, add lactic acid bacteria starter 100U / 1000L for acidification fermentation; when the pH of the milk drops to 6.5, add red yeast rice powder 0.01% (w / v ), stir well;

[0023] Rennet curd milk: add rennet 2% (w / v), and curd the milk for 50 minutes after stirring;

[0024] Drain the whey: cut the curd into 1cm 3 Stir slowly for 15 minutes to discharge 30% of the whey. When the pH value drops to 5.5, the whey is drained.

[0025] Mold forming: Add 2% salt (w / w) to the whey-drained curd cubes, put them into molds, and turn them over regularly.

[0026] Inoculation: the curd block is taken out from the mould, cut into cheese slices with a thickness ...

Embodiment 2

[0030] Standardization: Raw milk that has passed the inspection is standardized so that the ratio of protein to fat is 0.85 (w / w) to obtain raw milk.

[0031] Pasteurization: The sterilization condition is 72°C for 15s.

[0032] Acidification fermentation: Cool the pasteurized raw milk and keep the milk temperature at 34°C, add 150U / 1000L of lactic acid bacteria starter to carry out acidification fermentation;

[0033] When the pH of the milk drops to 6.5, add 0.04% (w / v) of red yeast rice flour and stir thoroughly;

[0034] Add red yeast rice flour: add rennet 2% (w / v), stir and curd for 40 minutes;

[0035] Drain the whey: cut the curd into 1cm 3 Small pieces, stirred slowly for 50 minutes, discharged 30% whey, when the pH value dropped to 5.8, the whey was discharged.

[0036] Mold forming: add salt 2.5% (w / w) to the whey-drained curd cubes, put them into molds, and turn them over regularly;

[0037] Inoculation: The curd block is taken out from the mould, cut into chee...

Embodiment 3

[0041] Standardization: The qualified raw milk is standardized so that the ratio of protein to fat is 0.9 (w / w);

[0042] Pasteurization: The sterilization condition is 72°C for 15s.

[0043] Acidification fermentation: After cooling, keep the milk temperature at 36°C, add lactic acid bacteria starter 200U / 1000L, and carry out acidification fermentation;

[0044] Add red yeast rice flour: when the pH of the milk drops to 6.5, add 0.08% (w / v) red yeast rice flour and stir thoroughly;

[0045] Rennet curd milk: Add 2% rennet (w / v), and curd the milk for 30 minutes after stirring.

[0046] Drain the whey: cut the curd into 1cm 3 Small pieces, stirred slowly for 100min, discharged 30% whey, when the pH value dropped to 6.0, the whey was discharged.

[0047] Mold forming: add 3% salt, put into the mold, and turn over regularly.

[0048] Inoculation: Take the curd block out of the mould, cut it into cheese blocks with a thickness of 5cm, spray the mixed bacterial solution of Pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com