Method for generating mesoporous molecular sieves through self-assembling in wood

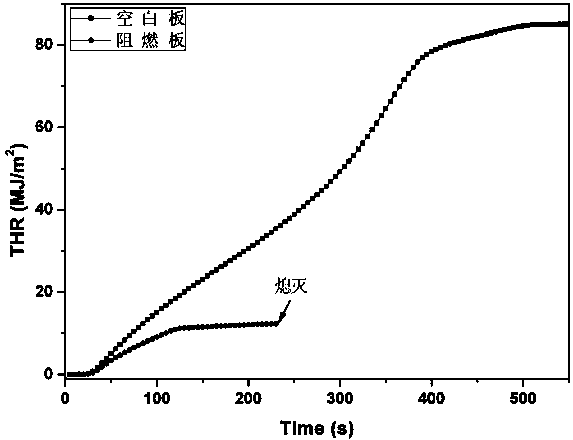

A mesoporous molecular sieve and self-assembly technology, applied in the fields of wood material property improvement, flame retardant and anti-corrosion, can solve the problems of easy loss, poor flame retardant effect of wood, short anti-corrosion aging, etc. Fungal, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Sol preparation: Dissolve 16 grams of F127 in 120 grams of ethanol and 10 grams of 0.2 mol / kg hydrochloric acid mixed solution at 30°C, stir for 1 hour, then add 20.8 grams of tetraethyl orthosilicate, and continue stirring for 1 hour Hours, a transparent precursor sol was obtained.

[0025] (2) Impregnation process: Put 20×20×10mm poplar sapwood in a sealed impregnation tank, vacuumize to 0.095Mpa, then inject the sol prepared in step (1), completely soak the wood for 3 hours; slowly empty , and then pressurize the dipping tank to 1.5 MPa, and continue soaking at 30° C. for 4 hours.

[0026] (3) Volatile self-assembly: the wood treated in step (2) was naturally volatilized at 40°C to remove the solvent, and then aged for 4 hours.

[0027] (4) Hydrothermal treatment: Transfer the poplar wood treated in step (3) to a sealed tank, heat-treat it in a water bath at 100°C for 24 hours, and then dry it to obtain a kind of mesopore that self-assembles in the porous struct...

Embodiment 2

[0029] (1) Sol preparation: Dissolve 10 grams of P123 in 115 grams of ethanol and 6 grams of 0.5 mol / kg hydrochloric acid mixed solution at 30°C, stir for 1 hour, then add 20.8 grams of ethyl tetramethoxysilicate, Stirring was continued for 2 hours to obtain a transparent precursor sol.

[0030] (2) Impregnation process: put a 100×100×10mm poplar board in a sealed dipping tank, vacuum to 0.001Mpa, then inject the sol prepared in step (1), and completely soak the poplar board for 2 hours; slowly empty, Next, pressurize 1 MPa to the dipping tank, and continue soaking at 40° C. for 6 hours.

[0031] (3) Volatile self-assembly: the poplar boards treated in step (2) were naturally volatilized at 40°C to remove the solvent, and then aged for 6 hours.

[0032] (4) Hydrothermal treatment: transfer the poplar board treated in step (3) into a sealed tank, heat-treat it in a water bath at 100°C for 36 hours, and then dry it to obtain a kind of mesopore that self-assembles in the porous ...

Embodiment 3

[0034] (1) Sol preparation: Dissolve 10 grams of P123 in 100 grams of ethanol and 10 grams of 0.2 mol / kg hydrochloric acid mixed solution at 30°C, stir for 2 hours, then add 20.8 grams of tetraethyl orthosilicate, and continue stirring for 1 Hours, a transparent precursor sol was obtained.

[0035] (2) Impregnation process: Put a 100×100×10mm poplar veneer in a sealed impregnation tank, evacuate to below 0.09Mpa, then inject the sol prepared in step (1), and completely soak the wood for 1 hour; slowly Empty, then pressurize the dipping tank to 0.5 MPa, and continue soaking at 30°C for 2 hours.

[0036] (3) Volatile self-assembly: the wood treated in step (2) was naturally volatilized at 30°C to remove the solvent, and then aged for 8 hours.

[0037](4) Hydrothermal treatment: Transfer the wood treated in step (3) to a sealed tank, heat it in a water bath at 80°C for 48 hours, and then dry it to obtain a mesoporous molecular sieve that self-assembles in the porous structure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com