Preparation method of ZSM-5 molecular sieve with multi-level pore channel structure

A ZSM-5, pore structure technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the complicated operation, the need for reasonable control to remove the template agent, the difficult to control the pore size, etc. problems, to achieve the effect of improving propylene yield and propylene selectivity, good structure and acid stability, and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

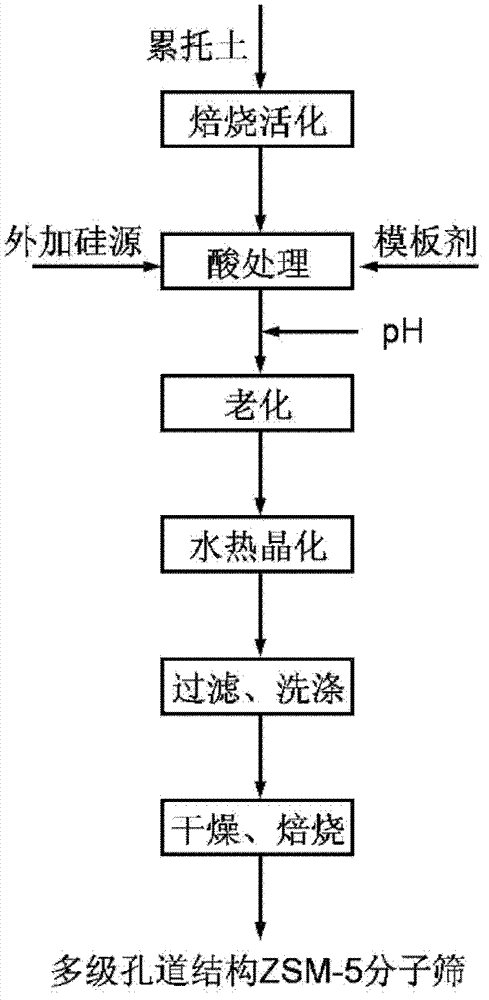

[0039] This embodiment provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the method comprising the following steps, the specific process is as follows figure 1 Shown:

[0040] Will commercially available rectorite (Hubei Mingliu rectorite Co., Ltd. production, its main component is: SiO 2 content of 43.2wt.%, Al2O3 content of 36.7wt.%, hereinafter the same) at 800 ° C for activation for 2 hours, set aside;

[0041] Add 5 g of activated retort earth to 400 g of 0.2 M hydrochloric acid solution, place in a water bath at 70°C and stir rapidly for 4 hours to obtain a mixture;

[0042] Add 129g of water glass, 8.9g of TPABr and 170g of deionized water to the above mixture in turn, and stir rapidly for 5min;

[0043] Adjust the pH value of the mixture to 10 with a sulfuric acid solution until it becomes a gel state to obtain a reactant gel;

[0044] Then the temperature of the water bath was raised to 80°C, and the gel was aged for ...

Embodiment 2

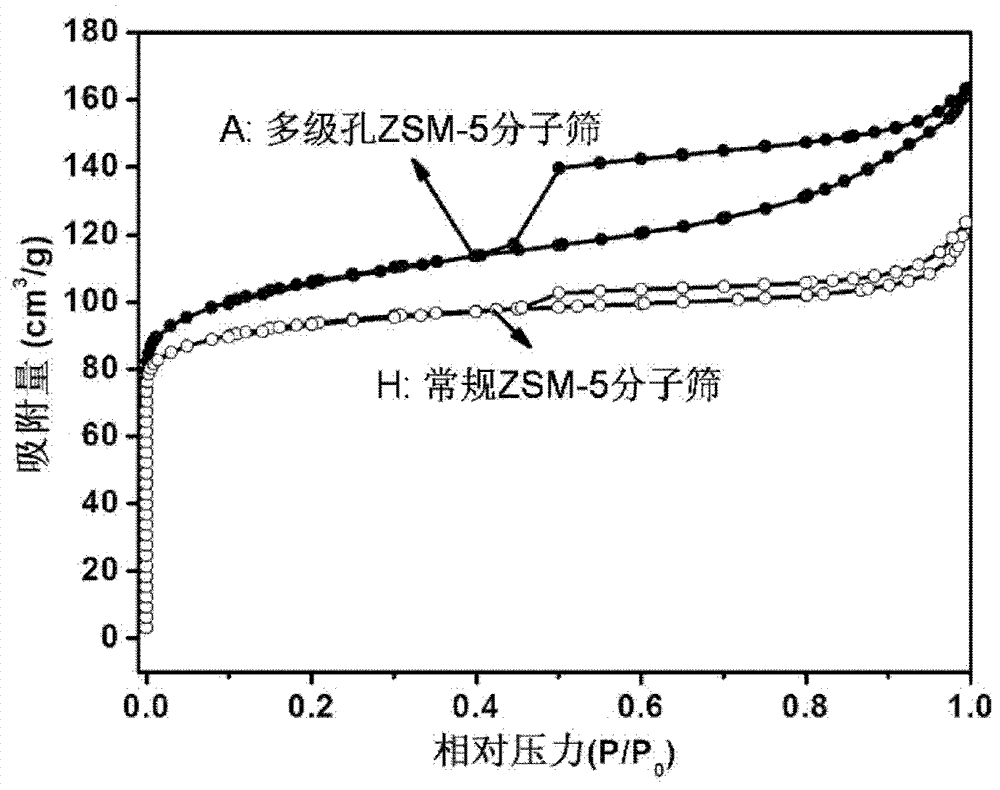

[0051] This example provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the method in Example 1, the difference is that in this example, the aging temperature of the gel is 70°C, and the aging time is 16h, and the obtained The product is denoted as B, and its mesopore volume is 0.17cm 3 / g, the micropore volume is 0.085cm 3 / g, the mesopore volume is twice that of the micropore volume, and the mesopore diameter is between 5-25nm.

Embodiment 3

[0053] This example provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the method of Example 1, the difference is that in this example, the amount of retort earth is 9g, the concentration of hydrochloric acid is 0.4M, deionized The amount of water is 519g, the amount of template agent is 26.6g, and the amount of water glass is 232g. The resulting product is denoted as C, and its mesopore volume is 0.15cm 3 / g, the micropore volume is 0.081cm 3 / g, the mesopore volume is 1.85 times that of the micropore volume, and the mesopore diameter is between 5-28nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com