Preparation method of micron gamma aluminum oxide with controllable morphology and mesoporous structure

A γ-alumina, mesoporous structure technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of many influencing factors, difficult to effectively control the morphology, structure and performance of alumina, and achieve simple preparation process operation. , safety cost, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

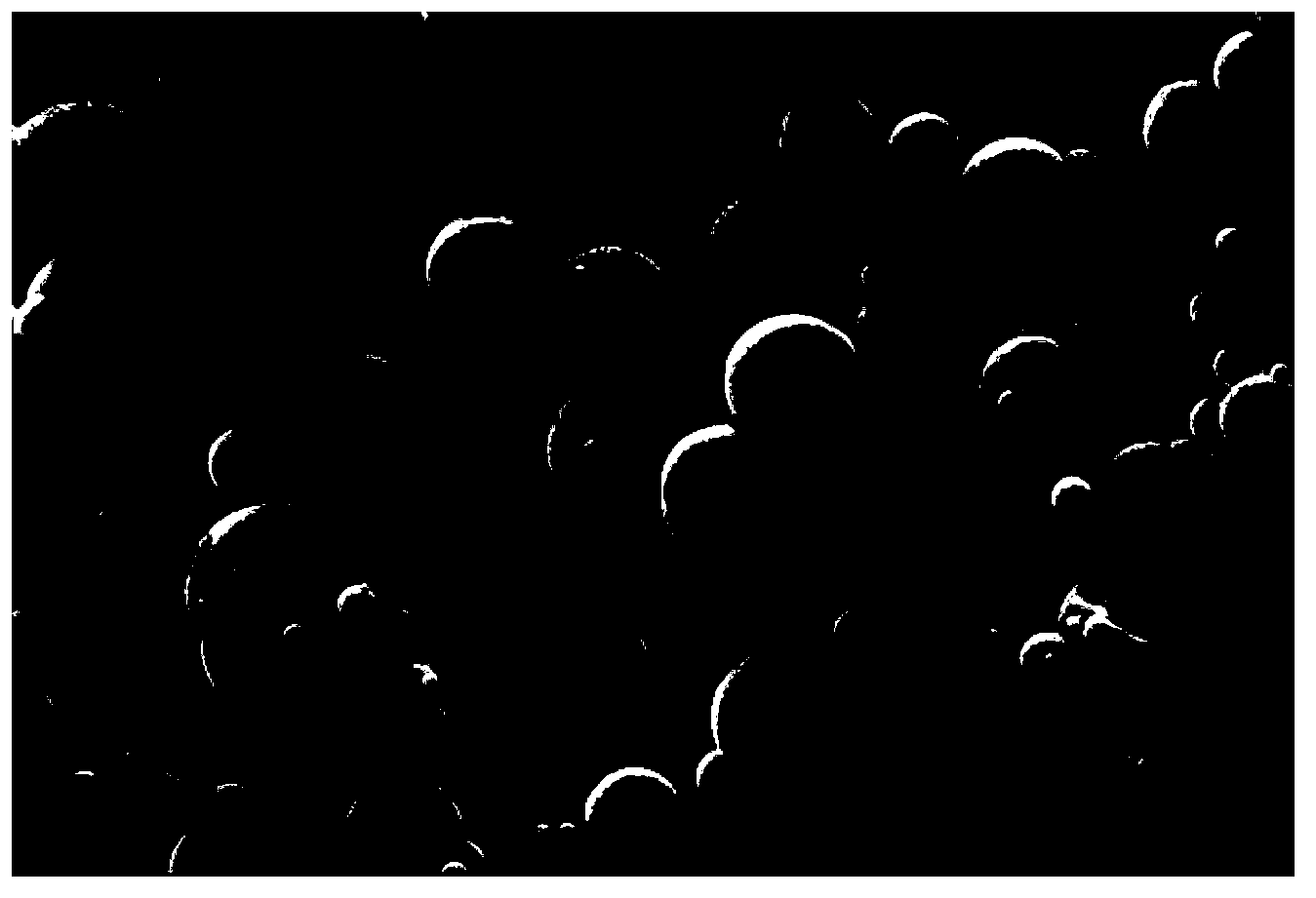

Embodiment 1

[0025] Take 0.35g of polyethylene glycol, 3.4g of aluminum trichloride hexahydrate, 2.52g of urea and 70mL of deionized water and magnetically stir and dissolve until uniform. The stirring speed is 200rpm and the time is 1.5 hours to obtain a mixed solution, which is the mother liquor. Then the mixed solution was transferred to a polytetrafluoroethylene liner and sealed in a hydrothermal kettle, and the hydrothermal kettle was subjected to microwave hydrothermal reaction at 80° C. for 6 hours. After natural cooling, a mixed solution of white precipitate and mother liquor was obtained, and then passed Centrifuge solid-liquid separation at a centrifugation speed of 4000 rpm for 3 minutes. Then wash with water and absolute ethanol 4 times each, wash the white precipitate, and dry it in an oven at 60°C for 12 hours to obtain the γ-alumina precursor, and finally the γ-alumina precursor is heated from room temperature to 10°C / min. 800°C, and at the same time keep at 800°C for 2 hour...

Embodiment 2

[0027] Take 5g of polyethylene glycol, 19.3g of aluminum trichloride hexahydrate, 50g of urea and 80mL of deionized water and magnetically stir and dissolve until uniform. The stirring speed is 300rpm and the time is 2 hours to obtain a mixed solution, which is the mother liquor. Then the mixed solution is transferred to a polytetrafluoroethylene liner and sealed in a hydrothermal kettle, and the hydrothermal kettle is subjected to a microwave hydrothermal reaction at 100° C. for 10 hours. After natural cooling, a mixed solution of white precipitate and mother liquor is obtained, and then passed Centrifuge solid-liquid separation at a centrifugation speed of 4000 rpm for 3 minutes. Then wash with water and absolute ethanol 5 times each, wash the white precipitate, and dry it in an oven at 80°C for 12 hours to obtain the γ-alumina precursor, and finally the γ-alumina precursor is heated from room temperature to 10°C / min. 820°C, at the same time, keep it at 820°C for 4 hours and...

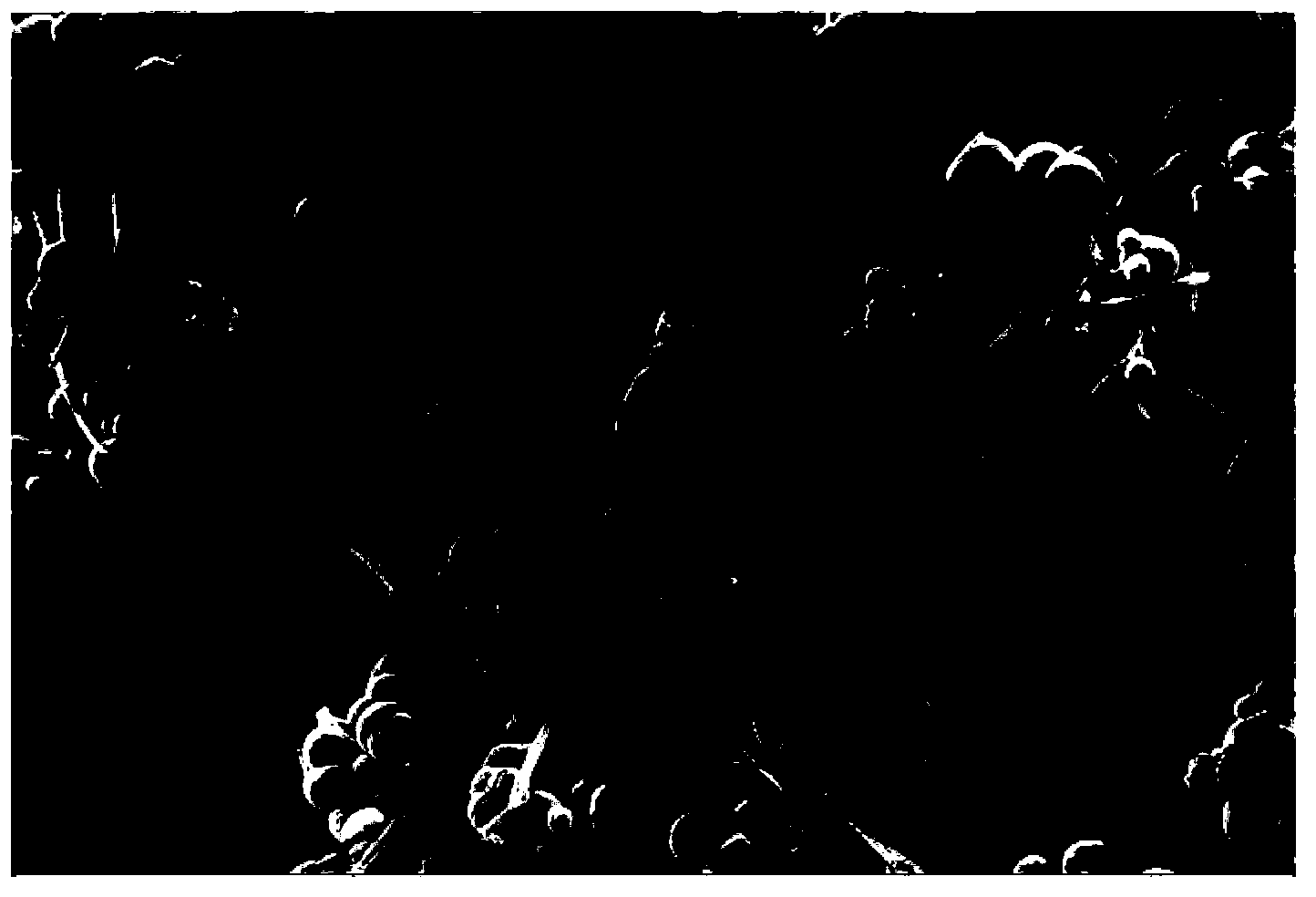

Embodiment 3

[0029] Take 4.4g of ammonium citrate, 10.5g of aluminum chloride hexahydrate, 55g of urea and 90mL of deionized water and magnetically stir and dissolve until uniform. The stirring speed is 400rpm and the time is 2.5 hours to obtain a mixed solution, that is, the mother liquor. Then the mixed solution is transferred to the polytetrafluoroethylene liner and sealed in the hydrothermal kettle, and the hydrothermal kettle was subjected to microwave hydrothermal reaction at 120° C. for 15 hours. After natural cooling, the mixed solution of white precipitate and mother liquor was obtained, and then Solid-liquid separation by centrifugation at a centrifugation speed of 4000 rpm for 3 minutes. Then wash with water and absolute ethanol 6 times each, wash the white precipitate, and dry it in an oven at 80°C for 12 hours to obtain a γ-alumina precursor. Finally, the γ-alumina precursor is heated from room temperature to 15°C / min. 840°C, and at the same time keep at 840°C for 6 hours and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com