Magnetic composite photocatalyst, preparation method and special system and method

A photocatalyst and composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, water treatment parameter control, etc., can solve problems such as low efficiency, high cost, secondary pollution, etc., and achieve improved separation efficiency, iron Effect of magnetic enhancement and strong oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

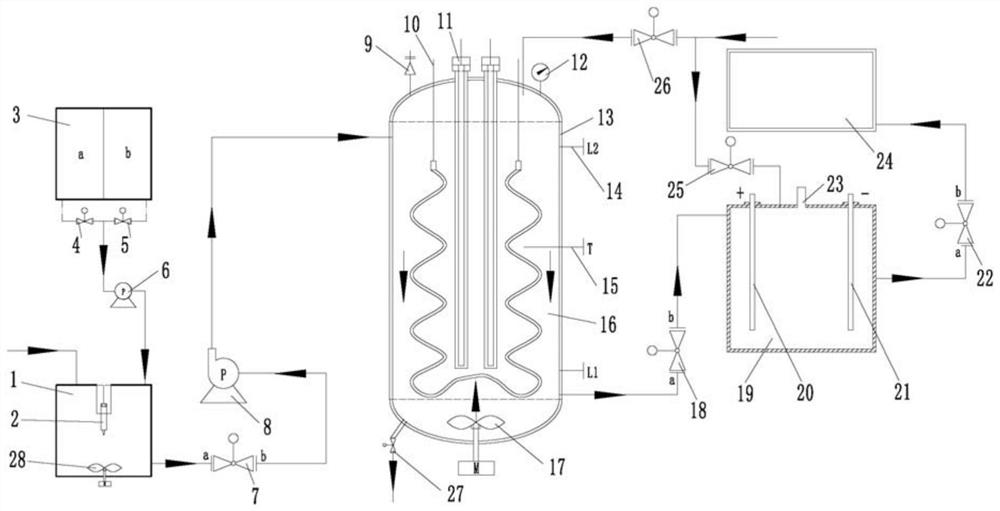

[0039] Such as figure 1 As shown, the special system for magnetic composite photocatalyst treatment of pharmaceutical intermediate wastewater includes a pH adjustment module, a photocatalytic reaction module, and a desalination module. Each module is connected by a pipeline, and a filter is installed in the pipeline. Wherein, the pH adjustment module includes a pH adjustment tank 1, an acid-base liquid storage tank 3 and a first metering pump 6. The pH adjustment tank 1 is provided with a pH sensor 2 at the top, and a first stirring paddle 28 is provided at the bottom, and the acid-base liquid storage tank 3 is divided into an acid solution area and an alkali solution area. An acid solution valve 4 is provided at the bottom of the acid solution area, and a lye solution valve 5 is provided in the lye solution area. The acid solution valve 4 and the lye solution valve 5 are adjusted with the pH by the first metering pump 6 Tank 1 is connected. The photocatalytic reaction module...

Embodiment 2

[0049] (1) Bi 5 Fe 0.9 Ni 0.1 Ti 2.7 co 0.3 o 15 preparation of

[0050] Weigh 3.64g of bismuth nitrate, 0.55g of iron nitrate, 0.05g of nickel nitrate, 0.13g of cobalt nitrate and 1.38g of tetrabutyl titanate in 20mL 4mol / L of In dilute nitric acid, stir magnetically for 0.5 h until the mixture is completely dissolved to obtain a mixed solution. Add 65mL of 1.4mol / L triethylenediamine solution dropwise into the mixed solution until the pH of the mixed solution reaches about 8, continue stirring for 1h to obtain liquid A, dissolve 1g of cetyltrimethylammonium bromide in 5mL of water to obtain Liquid B. Mix liquid A and liquid B under magnetic stirring for 1 h to obtain a cloudy liquid. This cloudy solution was transferred to a Teflon-lined autoclave to 80% of the autoclave volume. Continue to carry out thermal reaction in the blast drying oven, the reaction temperature is 180°C, and the reaction time is 48h. After the reaction, the precipitate was centrifuged, washed...

Embodiment 3

[0056] (1) Bi 5 Fe 0.5 Ni 0.5 Ti 2.1 co 0.9 o 15 preparation of

[0057] Weigh 3.4g of bismuth nitrate, 0.28g of iron nitrate, 0.21g of nickel nitrate, 0.37g of cobalt nitrate and 1g of tetrabutyl titanate in 20mL of 4mol / L diluted In nitric acid, stir magnetically for 0.5 h until the mixture is completely dissolved. Add 74mL of 1.6mol / L tetramethylammonium hydroxide solution dropwise into the mixed solution until the pH of the solution reaches about 8, continue stirring for 1h to obtain liquid A, and dissolve 5.25g of polyvinyl alcohol in 5mL of water to obtain liquid B. Mix liquid A and liquid B under magnetic stirring for 0.75 h to obtain a cloudy liquid. This cloudy solution was transferred to a Teflon-lined autoclave to 80% of the autoclave volume. Continue to carry out thermal reaction in the blast drying oven, the reaction temperature is 220°C, and the reaction time is 24h. After the reaction, the precipitate was centrifuged, washed three times with water, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com