Porous cellulose acetate composite micro/nano fiber membrane, centrifugal spinning preparation method and application of membrane in adsorbing heavy metal ions

A technology of cellulose acetate and nanofiber membranes, which is applied to artificial filaments made of cellulose derivatives, fiber treatment, chemical instruments and methods, etc., can solve the problems of low production efficiency and large amount of consumables, and achieve the preparation method Simple, high porosity, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Construction of Porous Cellulose Acetate Micro / Nanofibrous Membranes by Centrifugal Spinning

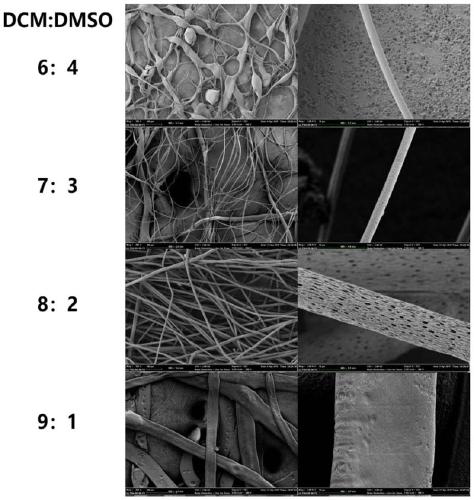

[0045] (1) Accurately weigh four parts of 1.3g cellulose acetate (CA) (wherein the molar mass M=100000g / mol of CA) with an analytical balance and place them in four 20ml sample bottles respectively, then pipette into the four sample bottles respectively. Take 5.22g DCM and 3.48g DMSO (mass ratio is 6:4), 6.09g DCM and 2.61g DMSO (mass ratio is 7:3), 6.96g DCM and 1.74gDMSO (mass ratio 8:2), 7.83g DCM and 0.87g DMSO (mass ratio: 9:1), seal the sample bottle with plastic wrap, raw tape and parafilm, heat to 35°C and stir for more than 12 hours to finally obtain a centrifugal spinning solution with evenly dispersed CA.

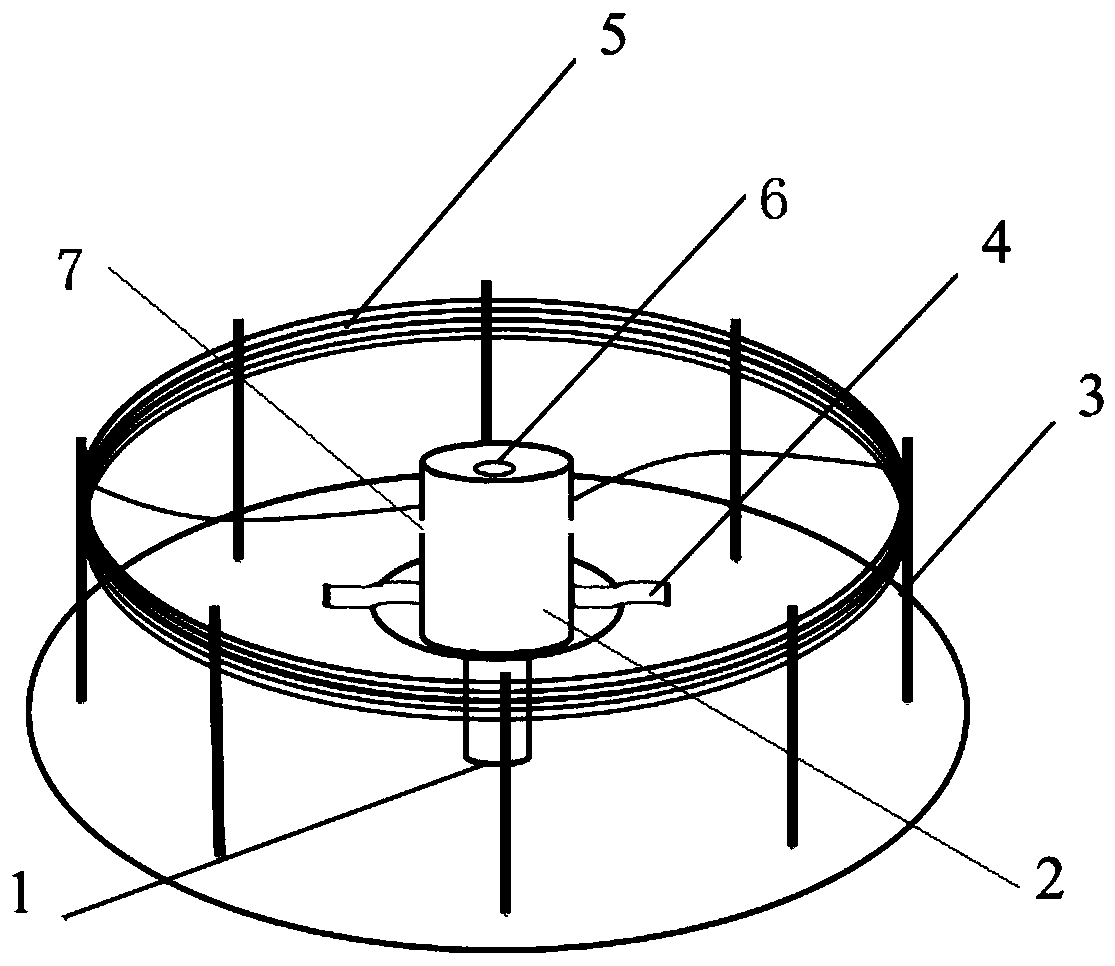

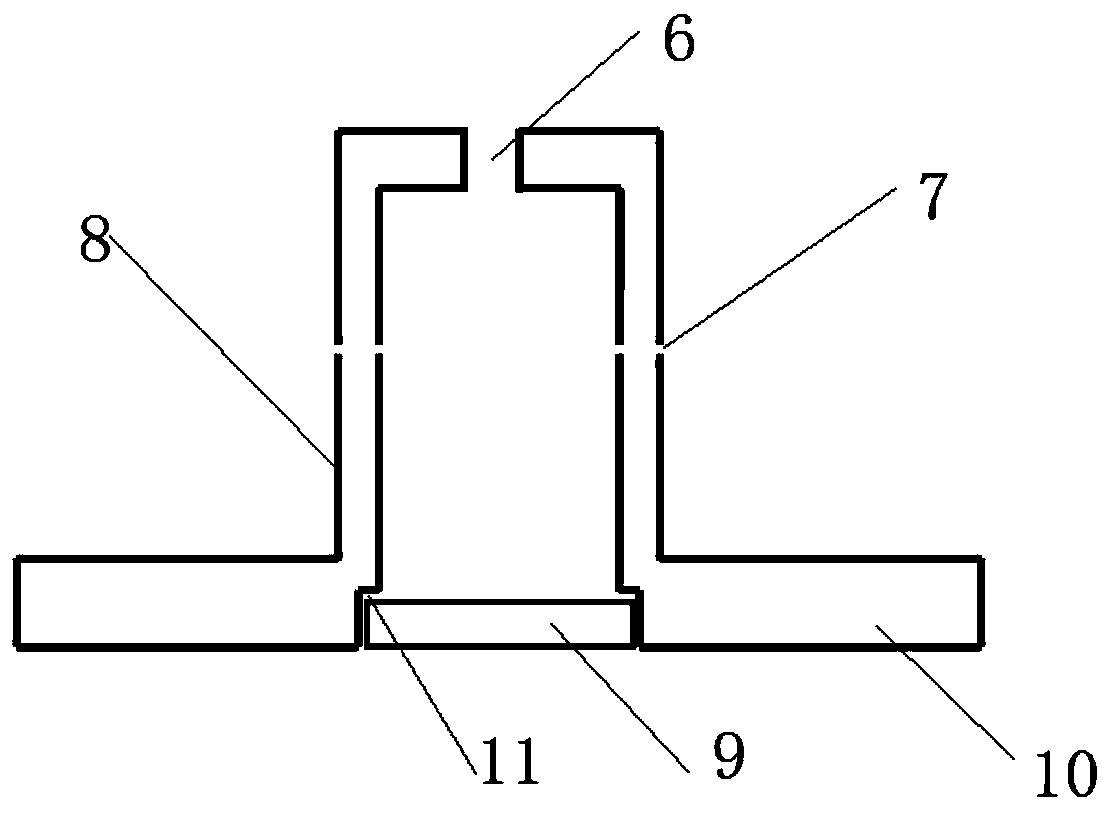

[0046] (2) adopt figure 1 The centrifugal spinning device shown is used for centrifugal spinning, the set speed is 8000rpm / min, the distance between the collecting rods is 10cm, and the diameter of the spinneret holes is 0.4mm. Take 5ml of the spinning solution ...

Embodiment 2

[0048] A kind of centrifugal spinning preparation method of porous cellulose acetate composite micro / nano fiber membrane, the specific steps of the method are as follows:

[0049] (1) Accurately weigh 1.3g CA, 0.05g (0.5%) MMT (placed in a 20ml sample bottle, pipette 6.92g DCM and 1.73g DMSO (mass ratio 8:2) into the sample bottle with an analytical balance. The sample bottle was sealed with plastic wrap, raw material tape and parafilm, heated to 35°C and stirred for more than 12 hours to finally obtain a centrifugal spinning solution with evenly dispersed CA.

[0050] (2) adopt figure 1 The centrifugal spinning device shown is used for centrifugal spinning, the set speed is 8000rpm / min, the distance between the collecting rods is 10cm, and the diameter of the spinneret holes is 0.4mm. Take 5ml of the spinning solution sample in the spinning head, turn on the motor, and pass through the collecting rods. A porous CA composite micro / nanofibrous membrane was obtained.

Embodiment 3

[0052] A kind of centrifugal spinning preparation method of porous cellulose acetate composite micro / nano fiber membrane, the specific steps of the method are as follows:

[0053] (1) Accurately weigh 1.3g CA and 0.1g (1%) MMT with an analytical balance and place it in a 20ml sample bottle, pipette 6.88g DCM and 1.72g DMSO (mass ratio 8:2) into the sample bottle, and the sample The bottle is sealed with a plastic wrap, a raw material tape and a sealing film, heated to 35° C. and stirred for more than 12 hours to obtain a centrifugal spinning solution.

[0054] (2) adopt figure 1 The centrifugal spinning device shown is used for centrifugal spinning, the set speed is 8000rpm / min, the distance between the collecting rods is 10cm, and the diameter of the spinneret holes is 0.4mm. Take 5ml of the spinning solution sample in the spinning head, turn on the motor, and pass through the collecting rods. A porous CA composite micro / nanofibrous membrane was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com