Method for preparing thermo-responsive iron-based nano-enzyme by reflux precipitation polymerization

A temperature-responsive, precipitation polymerization technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. The device is complicated and other problems, to achieve the effect of reasonable method, high conversion efficiency, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

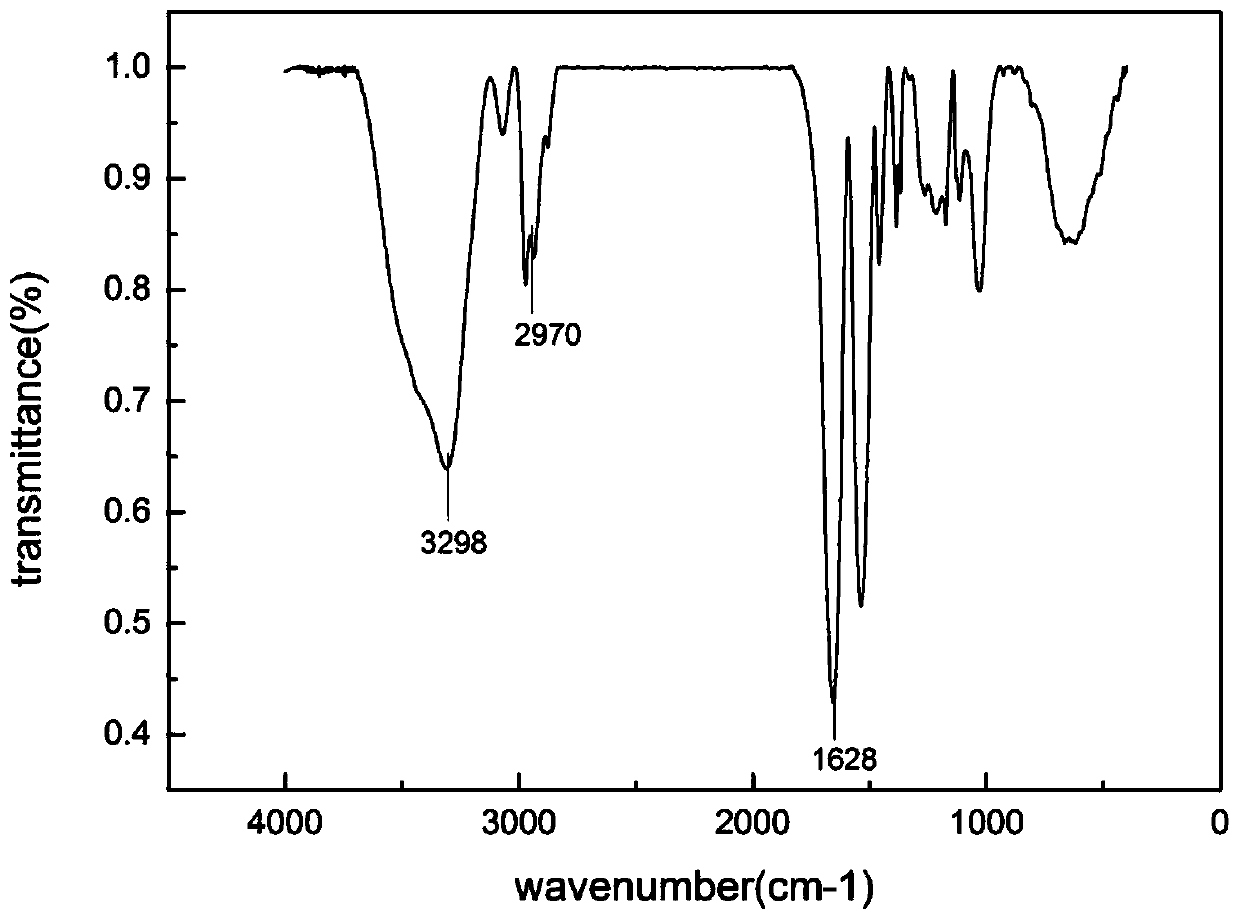

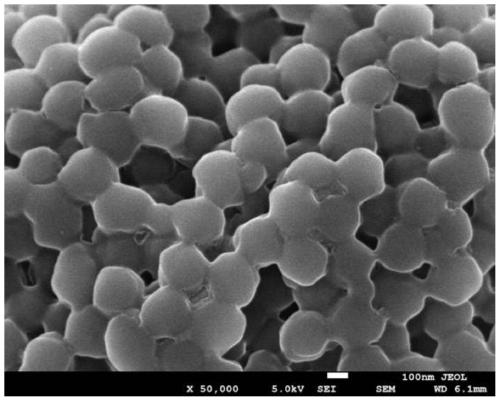

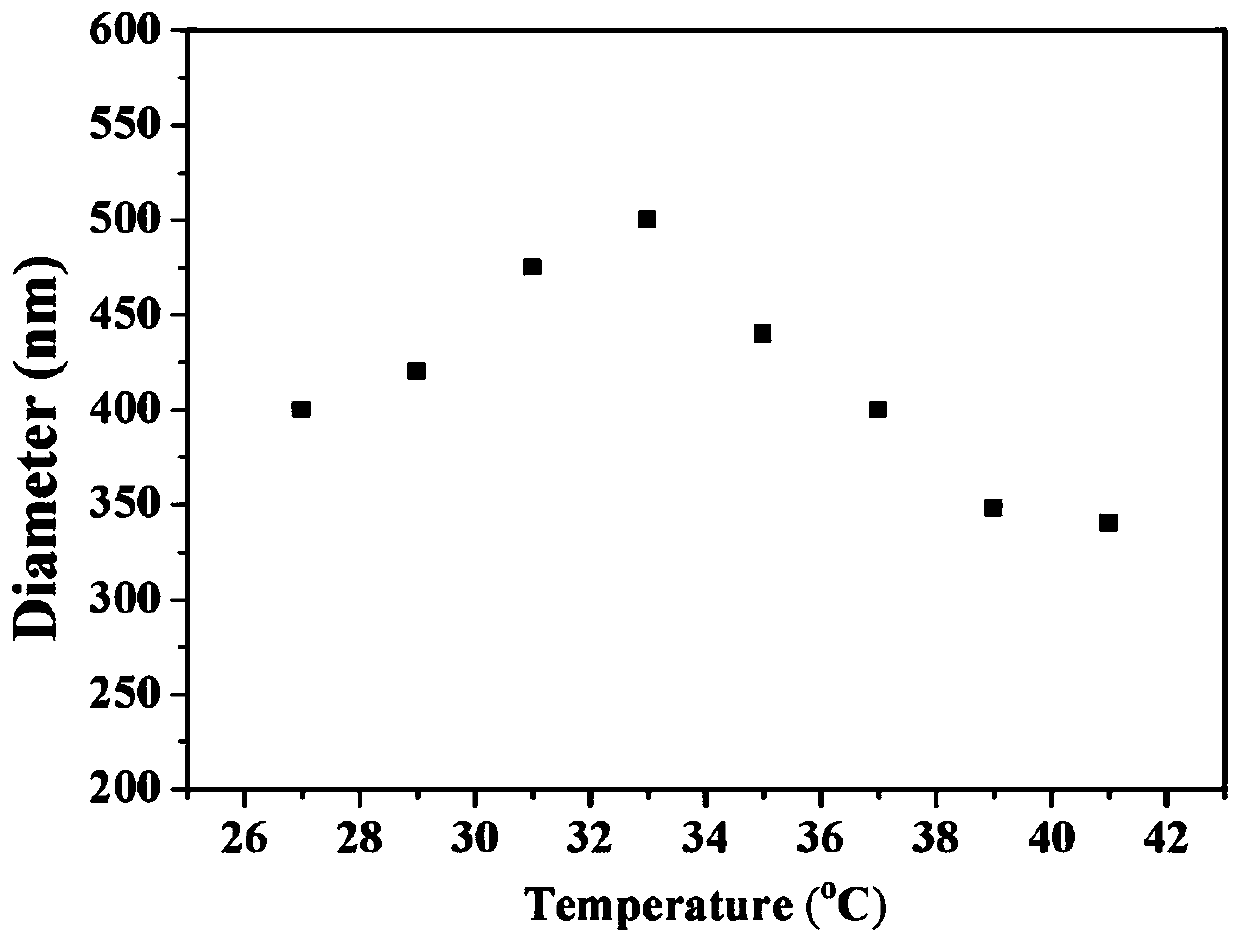

[0034] A method for preparing temperature-responsive iron-based nanozymes by reflux precipitation polymerization, comprising the following steps:

[0035] 1) Preparation of nano-microspheres:

[0036] Add 0.0303 g of N-methylolacrylamide (NHMA), 0.113 g of N-isopropylacrylamide (NIPAM), 0.022 g of N,N-methylenebisacrylamide into a 50 ml round bottom flask (MBA), 0.0044 g of azobisisobutyronitrile (AIBN) and 10 ml of acetonitrile solution, after the ultrasonic dispersion is uniform, put in the magnet, install the oil bath device, turn on the magnetic stirring, and heat the magnetic stirring at a stirring speed of 200 r / min, the temperature was raised to 85 °C to start the reaction, and the reaction was completed under constant temperature reflux for 2 h; the white emulsion was poured out, centrifuged at 4000 r / min for 10 min in a high-speed centrifuge, the upper layer solution was discarded, and the precipitate was washed with absolute ethanol Then carry out ultrasonic dispers...

Embodiment 2

[0042] A method for preparing temperature-responsive iron-based nanozymes by reflux precipitation polymerization, comprising the following steps:

[0043] 1) Preparation of nano-microspheres:

[0044] Add 0.202 g of N-methylolacrylamide (NHMA), 0.417 g of N-isopropylacrylamide (NIPAM), 0.264 g of N,N-methylenebisacrylamide into a 50 ml round bottom flask (MBA), 0.0220 g of azobisisobutyronitrile (AIBN) and 30 ml of acetonitrile solution, after the ultrasonic dispersion is uniform, put in the magnet, install the oil bath device, turn on the magnetic stirring, and heat the magnetic stirring at a stirring speed of 600 r / min, the temperature was raised to 90 °C to start the reaction, and the reaction was completed under constant temperature reflux for 2 h; the white emulsion was poured out and centrifuged at a speed of 4000 r / min for 10 min in a high-speed centrifuge, the upper layer solution was discarded, and the precipitate was washed with absolute ethanol Then carry out ultra...

Embodiment 3

[0050] A method for preparing temperature-responsive iron-based nanozymes by reflux precipitation polymerization, comprising the following steps:

[0051] 1) Preparation of nano-microspheres:

[0052] Add 0.1010 g of N-methylolacrylamide (NHMA), 0.3396 g of N-isopropylacrylamide (NIPAM), 0.1321 g of N,N-methylenebisacrylamide into a 50 ml round bottom flask (MBA), 0.0110 g of azobisisobutyronitrile (AIBN) and 20 ml of acetonitrile solution, after the ultrasonic dispersion is uniform, put in the magnet, install the oil bath device, turn on the magnetic stirring, and heat the magnetic stirring at a stirring speed of 300 r / min, the temperature was raised to 90 °C to start the reaction, and the reaction was completed under constant temperature reflux for 2 h; the white emulsion was poured out and centrifuged at a speed of 4000 r / min for 10 min in a high-speed centrifuge, the upper layer solution was discarded, and the precipitate was washed with absolute ethanol Then carry out ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com