Method for producing maleic acid methyl ester

A technology of dimethyl maleate and monomethyl maleate, applied in the production field of dimethyl maleate, can solve the problems of uneven catalyst distribution, frequent catalyst replacement, serious catalyst loss and the like, and saves catalysts , the effect of reducing the number of replacements and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

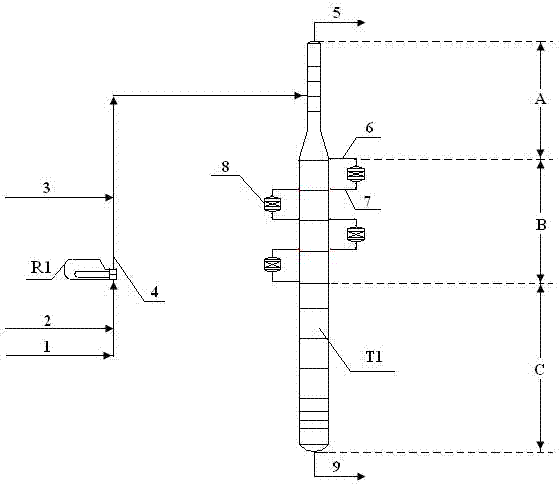

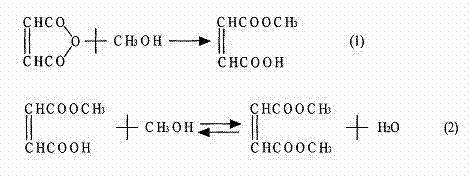

[0023] use figure 1 In the process shown, the total number of trays of the double esterification catalytic distillation tower is 30, of which there are 8 trays in the upper section, 9 trays in the middle section, and 13 trays in the lower section. No catalyst is loaded on the last 4 trays in the upper section, middle section and lower section. Four fixed-bed reactors are installed between adjacent trays in the middle section, and a total of 16 fixed-bed reactors are installed in the middle section of the entire catalytic distillation tower. The maleic anhydride stream 1 and the first methanol stream 2 enter the monoesterification reactor R1 to react to obtain a stream 4 containing monomethyl maleate. The stream 4 and the second methanol stream 3 enter the upper section of the double esterification catalytic distillation tower T1 from the side line to obtain the methanol-containing tower overhead stream 5 and the upper rectification effluent stream 6 . Stream 6 enters the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com