Laundry liquid using gel to stably disperse microcapsule essence and preparation technology thereof

A technology of microcapsule essence and laundry liquid, applied in the directions of detergent compounding agent, detergent composition, detergent composition fragrance, etc., to achieve the effects of improving rheology, short production cycle and unique physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw materials: see Table 1

[0024] Table 1

[0025] raw material name

Mass percentage%

AEO-7

1.5

AES

10

K-12

1.5

Ethylenediaminedimethyltetramine

2

sodium benzoate

0.1

Microcapsule flavor

0.5

Gel suspension concentrate 1% aqueous solution

84.4

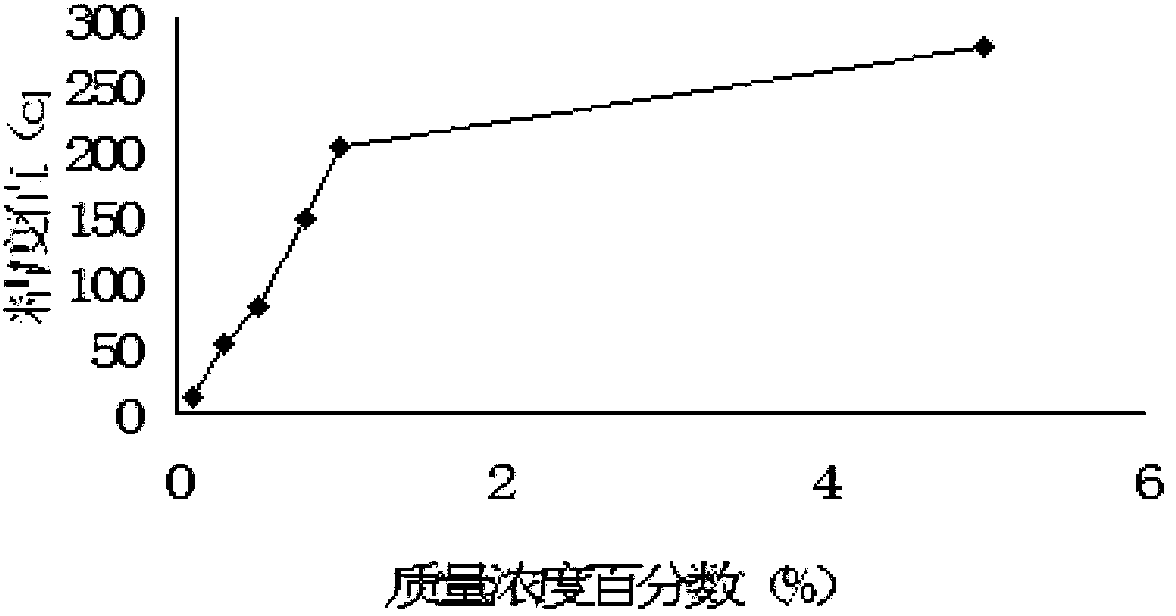

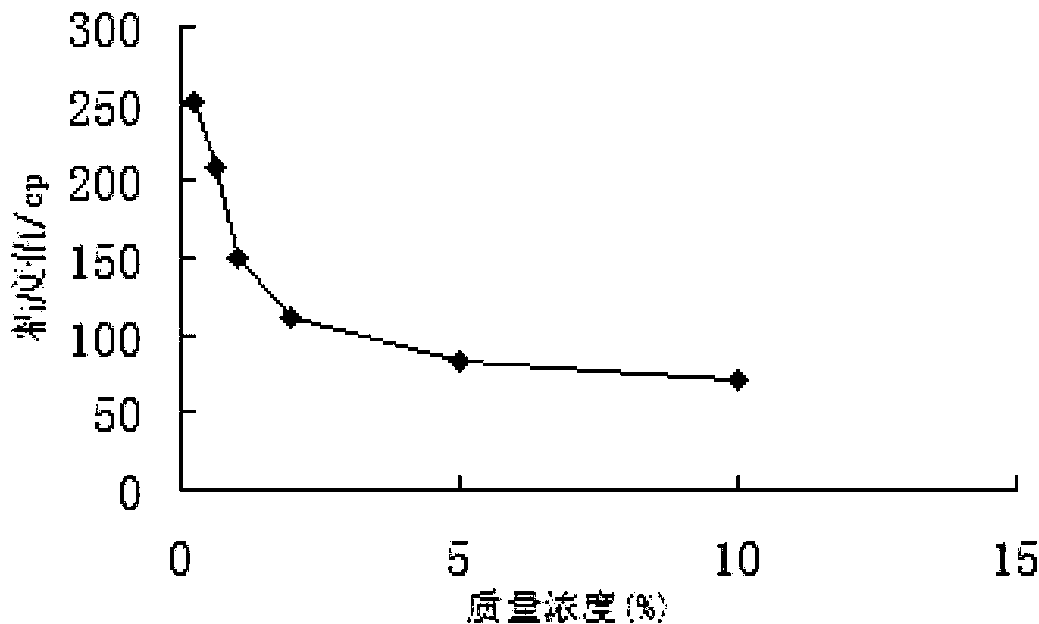

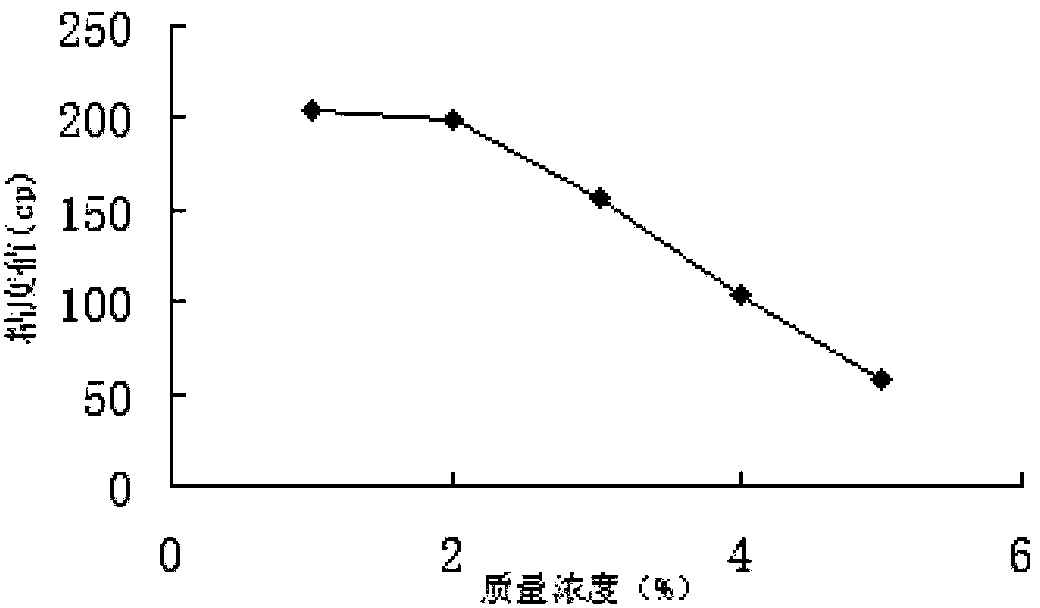

[0026] The determination of the above-mentioned raw materials is obtained through comparative experiments in several groups, wherein the gel suspending agent can be selected from one of low acyl gellan gum or high acyl gellan gum molecules or carboxymethylcellulose CMC or xanthan gum or Various, choose gellan gum to carry out experiment in the present embodiment, as Figures 1 to 4 As shown, comparing its influence on the viscosity of gellan gum solution, carboxymethylcellulose CMC or xanthan gum are also applicable:

[0027] a. The viscosity of gellan gum solution is affected by concentration, salt, sodium citrate, surfactant a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com