Test bench of comprehensive performance of air spring

A comprehensive performance and air spring technology, which is applied in the field of vehicle engineering, can solve the problems that the air spring cannot be tested vertically, laterally and torsionally, the working state of the air spring cannot be well simulated, and the dynamic analysis of the air spring is difficult. The data is true and reliable, the volume is continuously adjustable, and the test is convenient and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

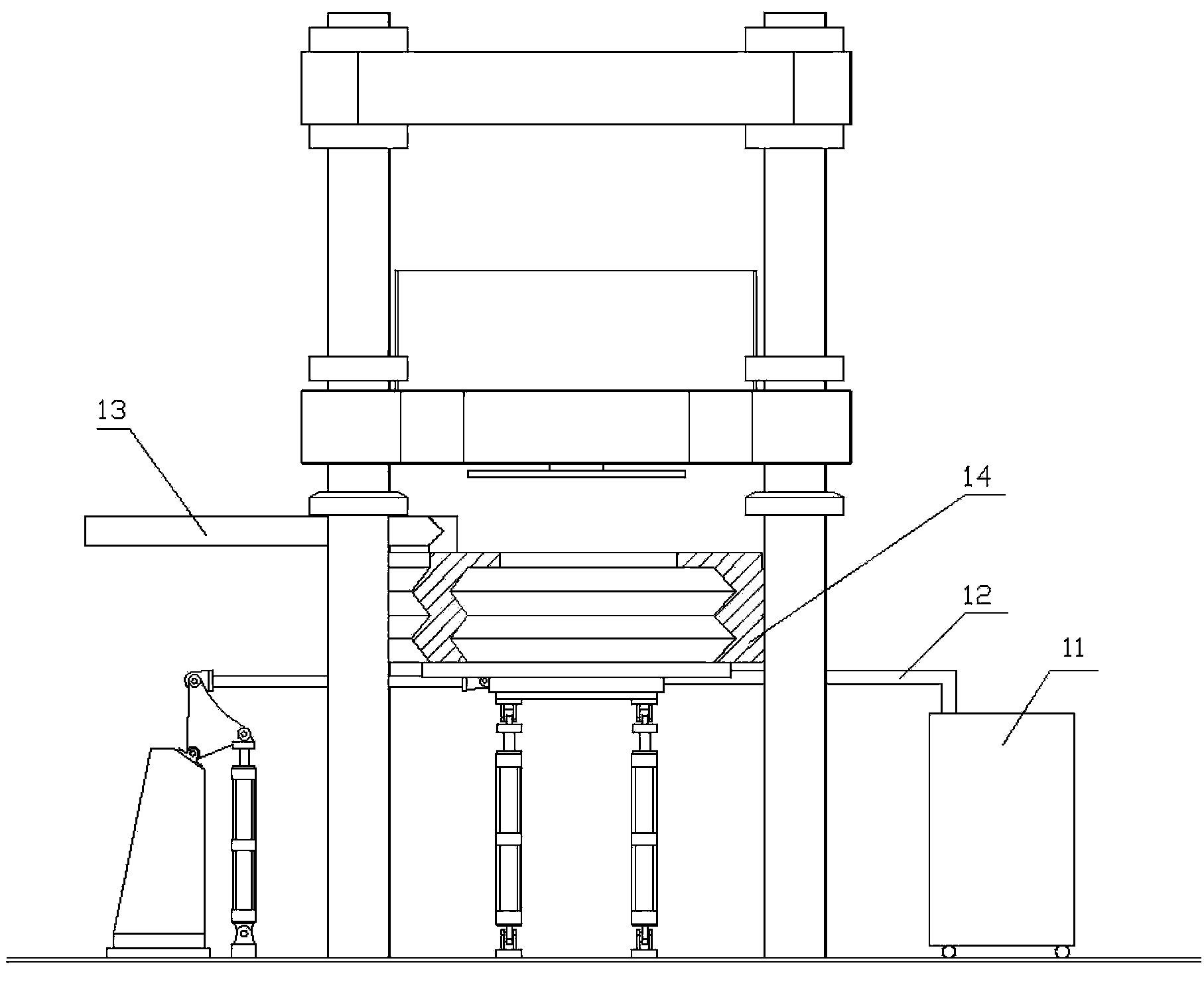

[0022] The present invention considers the influence of different physical parameters such as environmental temperature change and air spring capsule type, body volume, additional air chamber volume, orifice diameter, connecting pipeline length and diameter, excitation amplitude, and excitation frequency on the dynamic performance of the air spring. Impact.

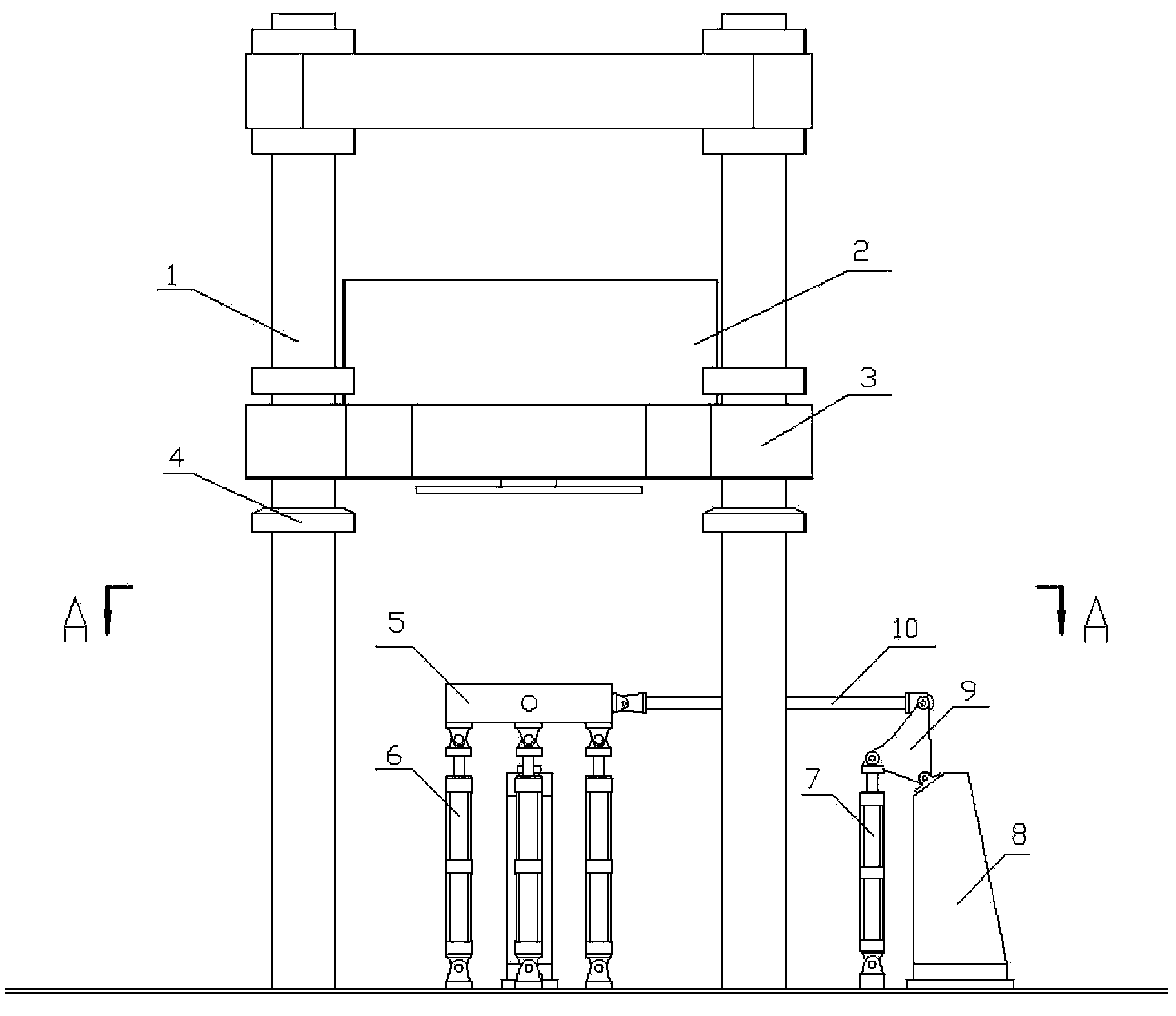

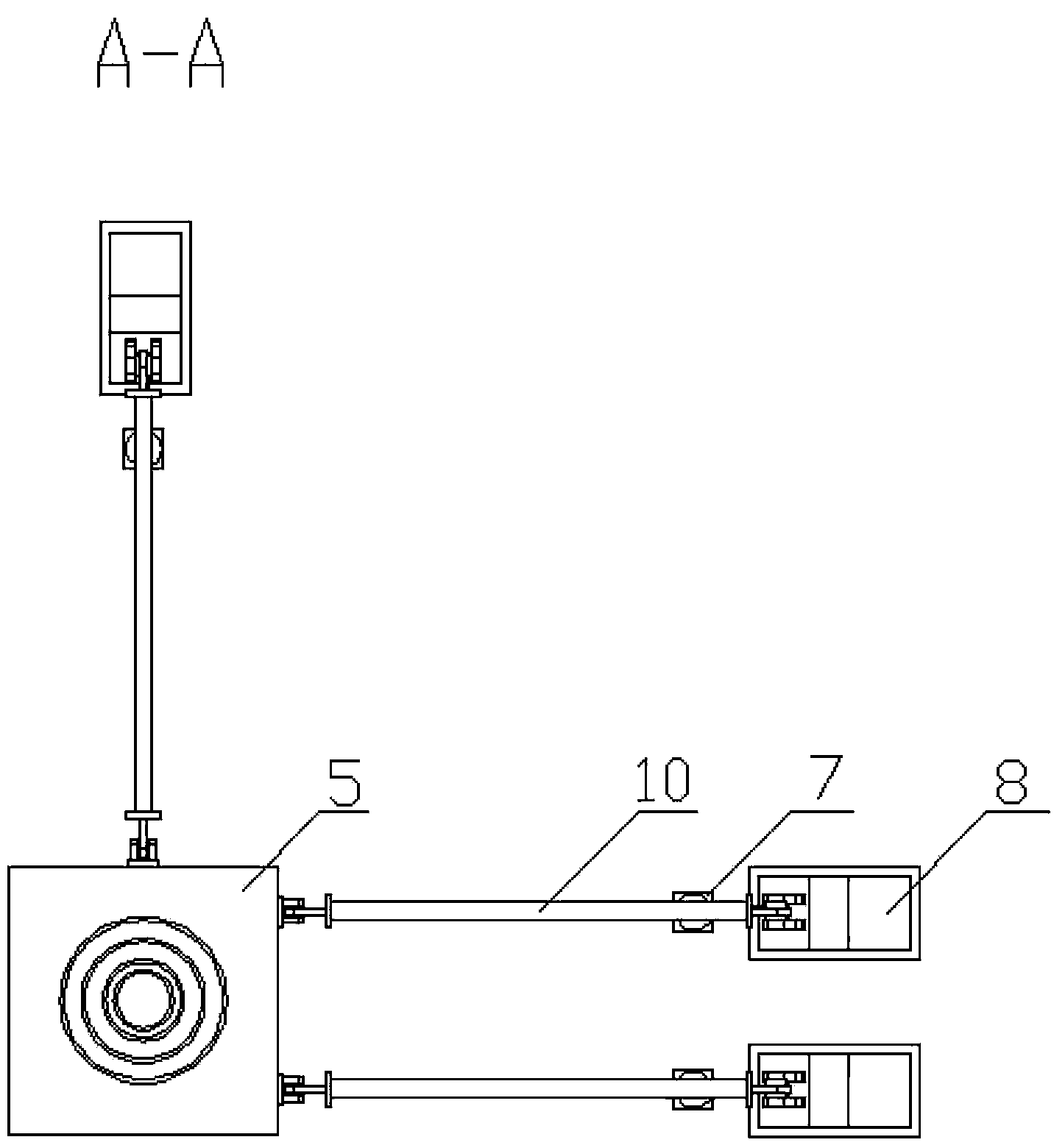

[0023] The present invention comprises a frame, an actuator, a hydraulic system, a high and low pressure gas storage tank and a compressor. The heavy device 2 is provided with a grid inside. The height value is marked on the column of the frame 1 and a tapered fixing nut 4 is provided. There is a taper between the upper surface of the fixing nut 4 and the lower surface of the bearing platform 3 and its mating surface; the upper surface of the workbench 5 has an annular groove , there are three double-spherical hinge vertical hydraulic actuators 6 arranged in a plane triangle below, and a double-hinge vertical hydraulic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com