A solar cell module

A technology for solar cells and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as low power and large internal resistance, and achieve the effects of easy commercial application, increased power, and improved photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This example details the solar module.

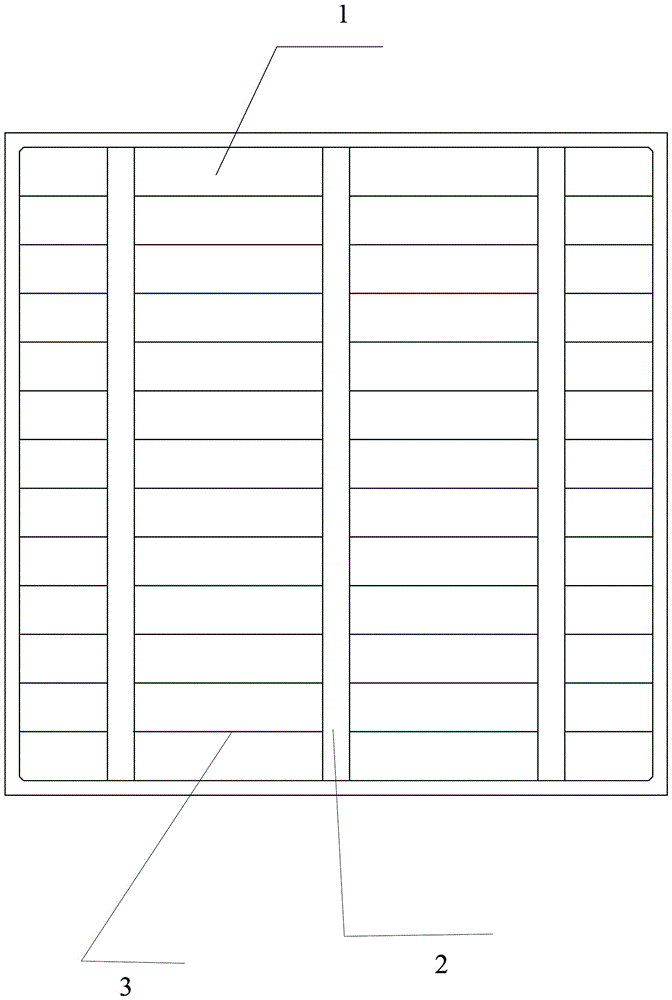

[0065] The electrode on the light-receiving surface refers to the current-leading electrode on the side that receives solar light, which is generally the negative electrode. figure 1 The light-receiving surface electrode is generally realized by printing several light-receiving surface electrode busbars 2 on the light-receiving surface of the solar cell 1, such as two or three light-receiving surface electrode busbars 2, and the light-receiving surface electrode busbar The line 2 is generally made by coating silver conductive paste and sintering. The current generated on the front of the solar cell can be collected on the main grid line 2 of the light-receiving surface electrode through a plurality of small sub-grid lines 3 connected to the light-receiving surface electrode. Lead out on gate line 2.

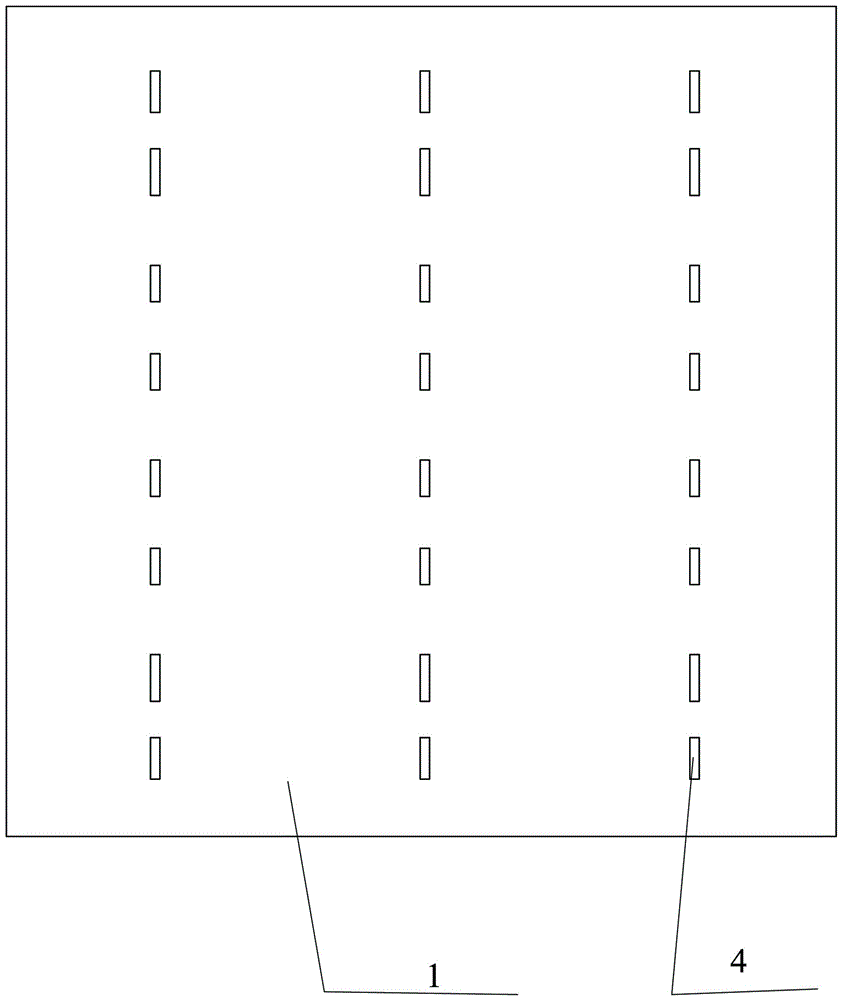

[0066] The backlight electrode is the current extraction electrode on the side coated with the back electric field, generally the...

Embodiment 60

[0074] Such as Figure 6 As shown, taking the series connection of two solar cells as an example, the two adjacent solar cells are defined as the first solar cell 11 and the second solar cell 12 respectively. In this way, each solar cell is welded with a ribbon, for example Figure 6 After the ribbon is welded on the first solar cell 11, the other half of the ribbon, i.e. the rectangle, is welded to the back electrode of the second solar cell 12, and then the operation is repeated to arrange the solar cells on the mold. In a row, in this way, a group of solar cell groups connected in series is completed, and then multiple groups of solar cell groups are connected in series to form a solar cell array. Or weld a triangular end of a ribbon on the light-receiving surface electrode of each solar cell, and then turn over each solar cell containing the ribbon, and weld the other end of the ribbon to the adjacent back electrode In this way, the string welding of solar cells is compl...

Embodiment 2

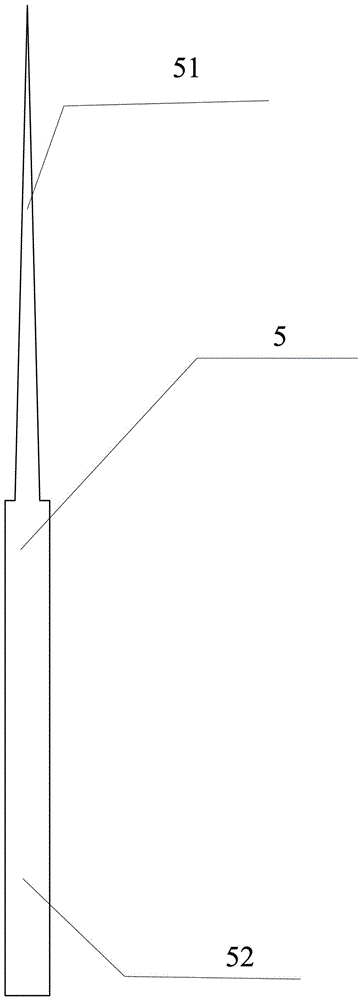

[0076] Adopt the same shape and size of the solar cell sheet as in embodiment 1, the electrode grid line printed on it is the same, adopt the conductive strip 5 of the same shape as in embodiment 1 to connect two adjacent solar cell sheets, the difference is that the isosceles triangle first The width of the widest part of the conductive strip connecting portion 51 , that is, the length of the base of the isosceles triangle is 2.5 mm, and the width of the rectangular second conductive strip connecting portion 52 is 4 mm. The size and number of solar cells 1 are the same as in Example 1, and the preparation method, the total length of the conductive strip 5 and the position and method of welding are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com