Method for preparing CIGS (copper indium gallium selenide) film with non-vacuum method

A non-vacuum, thin-film technology, applied in final product manufacturing, sustainable manufacturing/processing, coating, etc., can solve the problems of high investment cost and battery cost, difficult to control selenization process, low target utilization rate, etc. The effect of high utilization rate of raw materials, low production cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

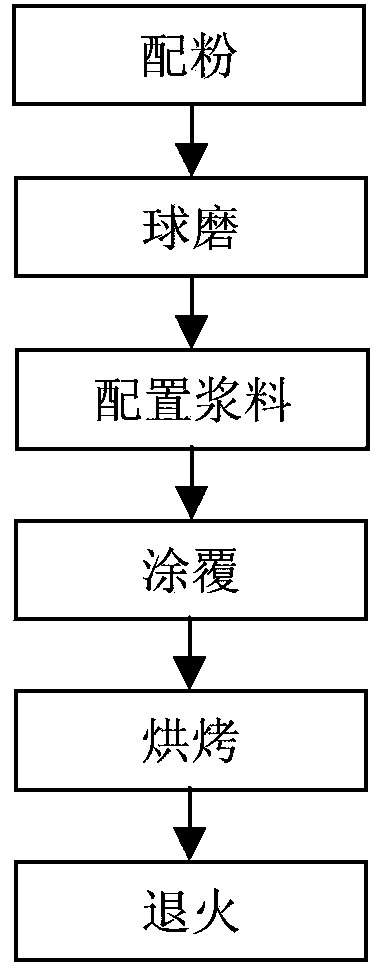

Method used

Image

Examples

Embodiment 1

[0036] (1) Mixing powder: cuprous selenide (Cu 2 Se), indium selenide (In 2 Se 3 ), gallium selenide (Ga 2 Se 3 ) three powders by CuIn 0.7 Ga 0.3 Se 2 Stoichiometric configuration as mixed powder

[0037] (2) Ball milling: the mixed powder is mixed with ZrO in a high-energy ball mill 2 Mill the balls in absolute ethanol until the average particle size of the powder is 0.6 μm, and use a laser particle size analyzer to measure the average particle size of the powder;

[0038] (3) Prepare the slurry: mix the ball-milled powder with ethanol to make a slurry;

[0039] (4) Coating: scrape the slurry on the surface of the glass substrate;

[0040] (5) Baking: Baking the substrate coated with the slurry at 100°C for 1 hour to remove the solvent to form a CIGS precursor film with a thickness of 1.5 μm;

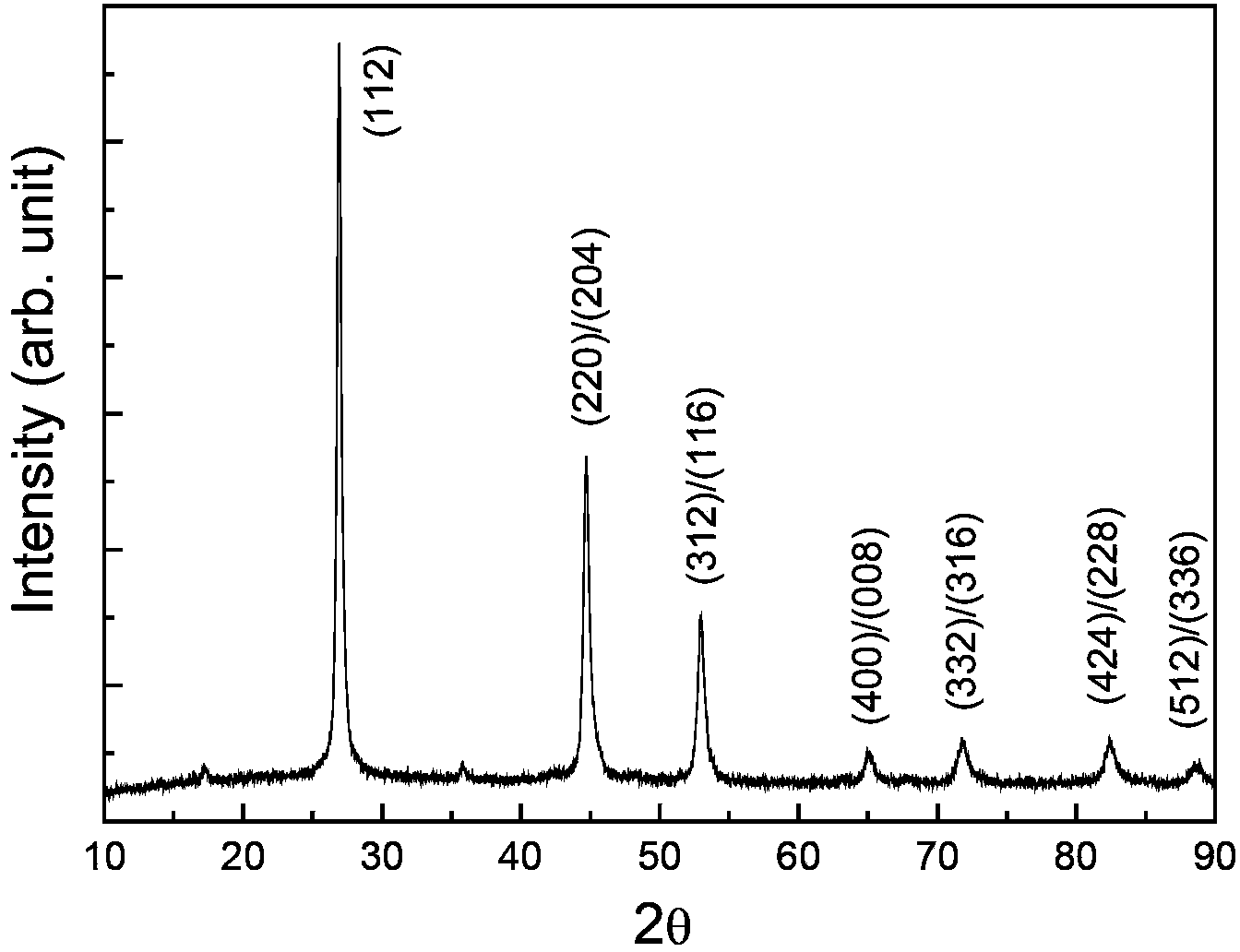

[0041] (6) Annealing: place the precursor film in H 2 Annealing treatment is carried out in Se+Ar mixed gas to form CIGS thin film. The annealing temperature is 550°C, the...

Embodiment 2

[0044] (1) Mixing powder: the purity of cuprous selenide (Cu 2 Se), indium selenide (In 2 Se 3 ), gallium selenide (Ga 2 Se 3) three powders by Cu 0.9 In 0.75 Ga 0.25 Se 1.95 The stoichiometric ratio is configured as a mixed powder;

[0045] (2) Ball milling: the mixed powder is ball-milled in absolute ethanol with agate balls in a high-energy ball mill until the average particle size of the powder is 1 μm, and the average particle size of the powder is measured by a laser particle size analyzer;

[0046] (3) Prepare slurry: mix the powder after ball milling with methanol to make slurry;

[0047] (4) Coating: Spin-coat the slurry on the surface of the stainless steel substrate;

[0048] (5) Baking: Baking the substrate coated with the slurry at 120°C for 0.5h to remove the solvent and form a CIGS precursor film with a thickness of 2 μm;

[0049] (6) Annealing: place the precursor film in solid selenium vapor and N 2 The annealing treatment is performed in a mixed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com