Coating conductor superconducting film and preparation method thereof

A technology of coated conductors and superconducting films, applied in the manufacture/processing of superconductor devices, permanent superconductor devices, etc., can solve the problems of failure to achieve homoepitaxial growth of superconducting layers, failure to achieve overall pinning of superconducting layers, etc. Achieve the effect of increasing thickness, improving purity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

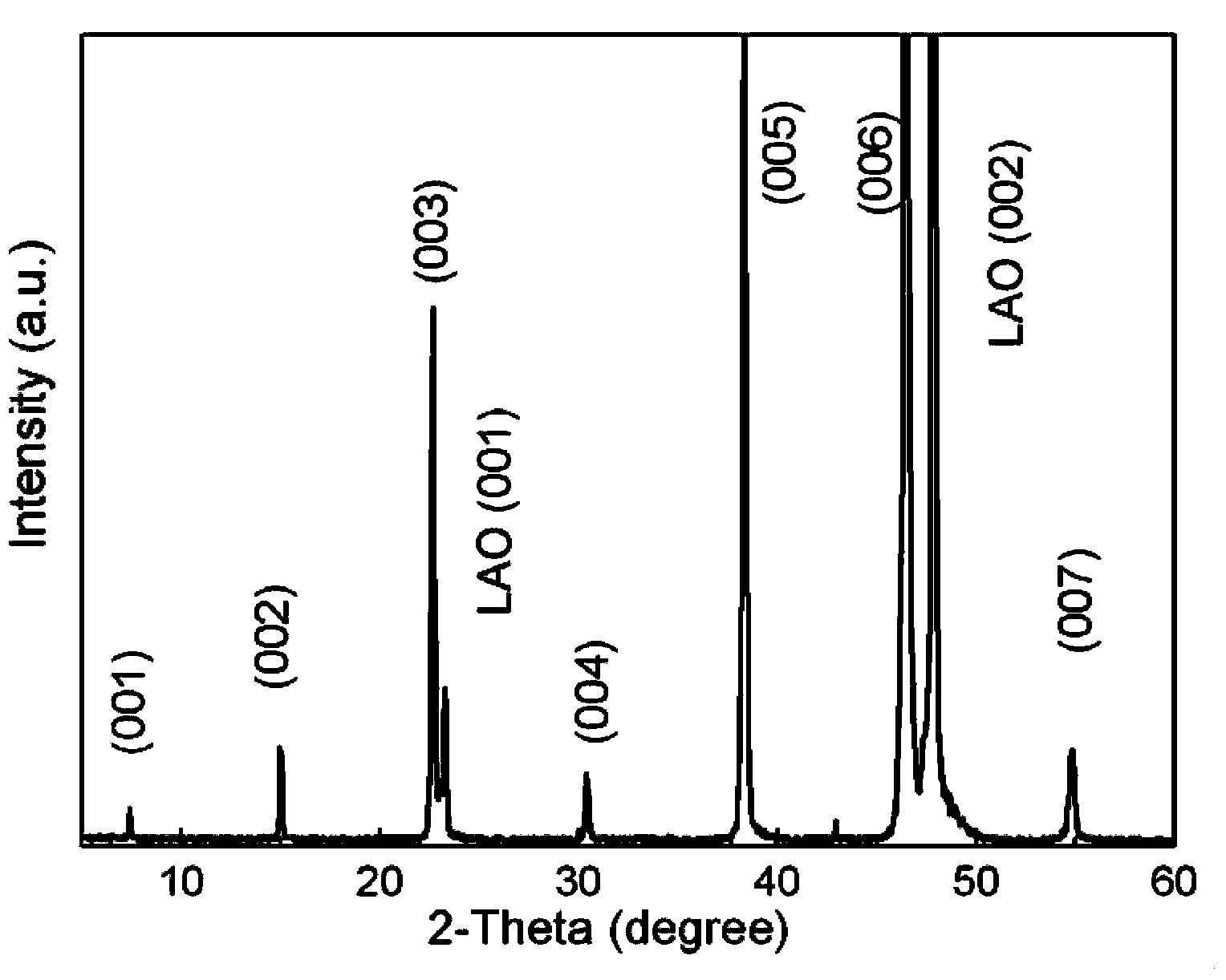

[0030] The superconducting film of this embodiment is made of YHf 0.02 Ba 2.02 Cu 3 o z superconducting layer and covered with YHf 0.02 Ba 2.02 Cu 3 o z Y on the surface of the superconducting layer 0.9 Gd 0.1 Ba 2 Cu 3 o y Film layer composition, where y is 6.8-7, z=y+0.06.

[0031] The preparation method of the coated conductor superconducting film of the present embodiment is:

[0032] Step 1. Combine YBCO powder with BaHfO 3 After the powders are mixed evenly, they are pressed under the condition of 8 MPa for 3 minutes to obtain a compact, and then the compact is sintered at a temperature of 900°C for 8 hours to obtain YBCO and BaHfO 3 The mixed target material, the atomic ratio of Y and Hf in the mixed target material is 1:0.02; then YBCO and BaHfO 3 The mixed target material is deposited on lanthanum aluminate (LAO) single crystal substrate (NiW / CeO can also be used 2 / YSZ / CeO 2 Buffer layer substrate) to obtain YHf with a thickness of 200nm 0.02 Ba 2.0...

Embodiment 2

[0039] The superconducting film of this embodiment is made of YHf 0.04 Ba 2.04 Cu 3 o z superconducting layer and covered with YHf 0.04 Ba 2.04 Cu 3 o z Y on the surface of the superconducting layer 0.9 Gd 0.1 Ba 2 Cu 3 o y Film layer composition, where y is 6.8-7, z=y+0.12.

[0040] The preparation method of the coated conductor superconducting film of the present embodiment is:

[0041] Step 1. Combine YBCO powder with BaHfO 3 After the powders are mixed evenly, they are pressed under the condition of 10MPa for 1min to obtain a compact, and then the compact is sintered at a temperature of 900°C for 10h to obtain YBCO and BaHfO 3 The mixed target material, the atomic ratio of Y and Hf in the mixed target material is 1:0.04; then YBCO and BaHfO 3 The mixed target material is deposited on lanthanum aluminate (LAO) single crystal substrate (NiW / CeO can also be used 2 / YSZ / CeO 2 buffer layer substrate) to obtain a thickness of 300nm YHf 0.04 Ba 2.04 Cu 3 o z S...

Embodiment 3

[0048] The superconducting film of this embodiment is made of YHf 0.035 Ba 2.035 Cu 3 o z superconducting layer and covered with YHf 0.035 Ba 2.035 Cu 3 o z Y on the surface of the superconducting layer 0.9 Gd 0.1 Ba 2 Cu 3 o y Film layer composition, where y is 6.8-7, z=y+0.105.

[0049] The preparation method of the coated conductor superconducting film of the present embodiment is:

[0050] Step 1. Combine YBCO powder with BaHfO 3 After the powders are mixed evenly, they are pressed under the condition of 7 MPa for 5 minutes to obtain a compact, and then the compact is sintered at a temperature of 900°C for 5 hours to obtain YBCO and BaHfO 3 The mixed target material, the atomic ratio of Y and Hf in the mixed target material is 1:0.035; then YBCO and BaHfO 3 Deposition of mixed targets onto NiW / CeO 2 / YSZ / CeO 2 On the buffer layer substrate (lanthanum aluminate single crystal substrate can also be used), a YHf with a thickness of 250nm 0.035 Ba 2.035 Cu 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com