Method for treating reverse osmosis concentrate

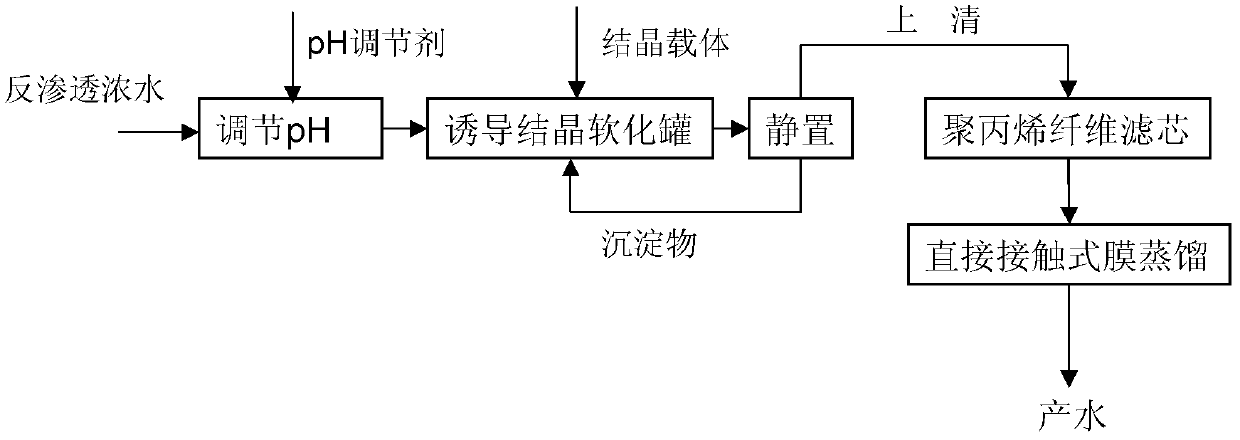

A technology of reverse osmosis concentrated water and treatment method, applied in the field of industrial water treatment, can solve the problems of increased operating pressure and serious membrane fouling, and achieve the effects of improving efficiency, reducing membrane fouling and high production water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

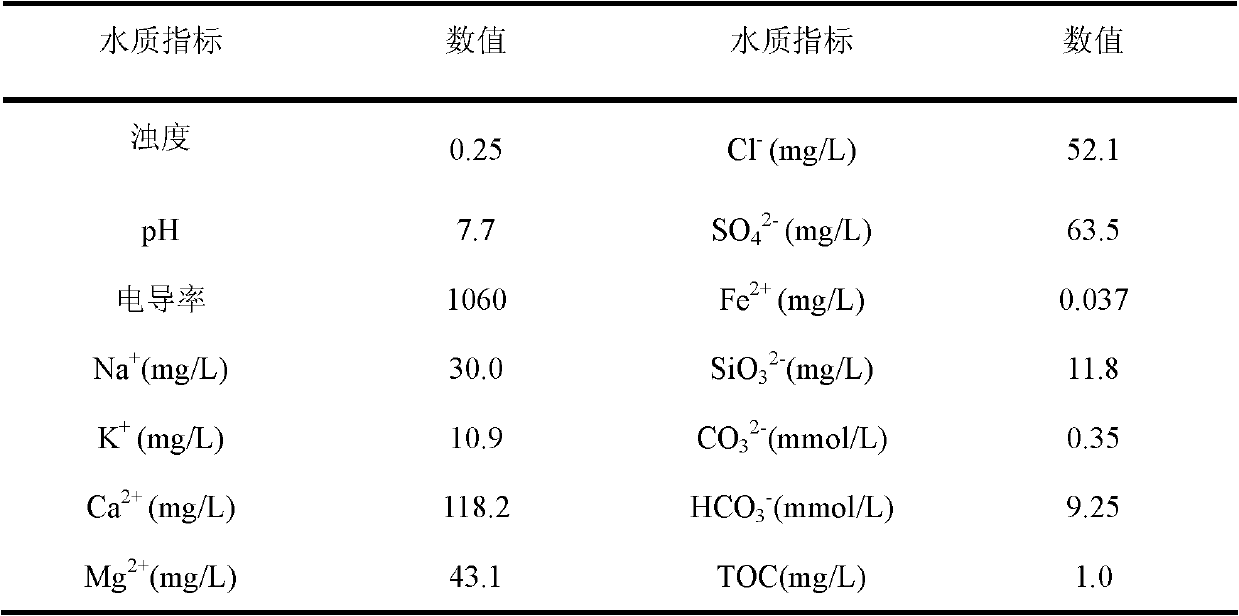

[0061] The first-stage reverse osmosis water production rate of a direct drinking water system is 50%, and the water quality of the first-stage reverse osmosis concentrated water is shown in Table 1.

[0062] Table 1 Water quality of primary reverse osmosis concentrated water in direct drinking water system

[0063]

[0064] 1. Adjust the pH value of reverse osmosis concentrated water

[0065] Add a NaOH solution with a concentration of 1mol / L to the first-stage reverse osmosis concentrated water of the direct drinking water system described in Table 1 above with a volume of 10 L, and adjust the pH value of the concentrated water to 10.10;

[0066] 2. Crystallization treatment

[0067] Add the crystallization-inducing carrier CaCO with a weight of 50 g and a particle size of 0.1-0.5 mm to the concentrated water after adjusting the pH value under stirring. 3 , carry out the crystallization reaction, the stirring and crystallization treatment time is 1.5h, and after the rea...

Embodiment 2

[0073] The water production rate of the first-stage reverse osmosis in a power plant is 60%, and the water quality of the first-stage reverse osmosis concentrated water is shown in Table 2.

[0074] Table 2 Water quality of primary reverse osmosis concentrated water in power plants with reverse osmosis water production rate of 60%

[0075]

[0076] 1. Adjust the pH value of reverse osmosis concentrated water

[0077] Adding NaOH solution and 10g sodium carbonate with a concentration of 1mol / L to the first-level reverse osmosis concentrated water of the power plant described in the above table 2 with a volume of 5L, adjusting the pH value of the concentrated water to 12.10, the sodium carbonate added in every 1L of reverse osmosis concentrated water The weight is 2g;

[0078] 2. Crystallization treatment

[0079] Add the crystallization-inducing carrier CaCO with a weight of 35 g and a particle size of 0.2-0.4 mm to the concentrated water after adjusting the pH value under...

Embodiment 3

[0085] The water production rate of the primary reverse osmosis in a power plant is 65%, and the concentrated water quality of the primary reverse osmosis is shown in Table 3.

[0086] Table 3 Water quality of primary reverse osmosis concentrated water in power plants with reverse osmosis water production rate of 65%

[0087]

[0088] 1. Adjust the pH value of reverse osmosis concentrated water

[0089] Add the NaOH solution and 9.5g sodium carbonate with a concentration of 1mol / L to the power plant first-level reverse osmosis concentrated water described in the above table 2 with a volume of 5L, adjust the pH value of the concentrated water to 11.50, and the carbonic acid added in every 1L of reverse osmosis concentrated water The weight of sodium is 1.9g;

[0090] 2. Crystallization treatment

[0091] Add the crystallization-inducing carrier CaCO with a weight of 15 g and a particle size of 0.1-0.5 mm to the concentrated water after adjusting the pH value under stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com