Application of sulfo group mesoporous organic silicon catalyst

A sulfonic acid-based mesoporous, solid acid catalyst technology, used in organic chemistry, isomerization hydrocarbon production, etc., can solve the problems of poor stability, easy deactivation, rapid deactivation, etc., to achieve catalyst stability, high activity and selectivity performance, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

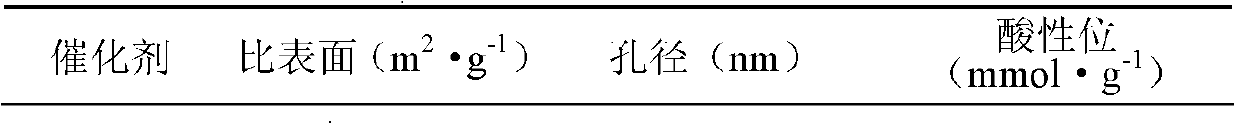

[0016] Embodiment 1 prepares catalyst

[0017] Octadecyltrimethylammonium chloride (ODTMA, 7.91g) was dissolved in 3mol / L NaOH aqueous solution (224.0mL), and then 1,2-bis(triethoxysilyl)ethane ( BTEE, 11.0 g) and 3-mercaptopropyltriethoxysilane (MPTMS, 2.04 g). The resulting suspension was stirred at room temperature for 20 hours and then at 95° C. for 24 hours. Filtration yielded a white precipitate. The precipitate was washed with a solution of hydrochloric acid (36% HCl, 3.0 g) in ethanol (200 mL) at 70° C. for 12 hours to remove the surfactant. Then at room temperature, with 65% HNO 3 Process for 24 hours. The product is then washed with a large amount of hot water to remove HNO 3 , and finally dried to obtain the final product A: sulfoethyl-linked HMM, namely Et-HMM-SO 3 , labeled Catalyst A.

Embodiment 2

[0018] Embodiment 2 prepares catalyst

[0019] Octadecyltrimethylammonium chloride (ODTMA, 7.93g) was dissolved in 3mol / L NaOH aqueous solution (224.0mL), and then 1,2-di(tripropoxysilyl)ethane ( BTEE, 15.8 g) and 3-mercaptopropyltriethoxysilane (MPTMS, 2.04 g). Other is with embodiment 1, makes Pr-HMM-SO 3 , namely Catalyst B.

Embodiment 3

[0020] Embodiment 3 prepares catalyst

[0021] Octadecyltrimethylammonium chloride (ODTMA, 7.92g) was dissolved in 3mol / L NaOH aqueous solution (275.0mL), and then 1,4-bis(triethoxysilyl)benzene (BTEB , 7.92g) and 3-mercaptopropyltriethoxysilane (MPTMS, 1.27g). Next step is the same as embodiment 1, makes Ph-HMM-SO 3 , namely catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com