Radiation-protection filtering contact lenses and production method therefor

A technology for contact lenses and production methods, applied in the directions of glasses/goggles, optics, optical components, etc., can solve the problems of low ultraviolet light protection performance, unsightly appearance, and reduced light brightness of sunglasses, and achieves protection against photochemical damage and moisture. The effect of good rate and good oxygen transmission coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Hydroxyethyl methacrylate: 90 parts;

[0071] n-vinylpyrrolidone: 10 parts;

[0072] Ethylene glycol dimethacrylate: 0.3 parts;

[0073] Azobisisobutyronitrile: 0.15 parts;

[0074] 0.7 parts of azophenyl methacrylate.

[0075] The method for making a contact lens using the contact lens material of this implementation may include the following steps in turn:

[0076] Step (1) making a half-mold: making a convex mold, the curvature of the inner side of the bottom is the same as that of the contact lens, as a forming mold for the contact lens.

[0077] The half-mold making process includes:

[0078] (1) Drying of raw materials: Put an appropriate amount of PBT granular raw materials into a dryer for drying and then take them out for use;

[0079] (2) Injection molding machine preparation: connect the power supply of the injection molding machine, turn on the power supply, make the injection molding machine barrel and injection molding heating part reach the required ...

Embodiment 2-5

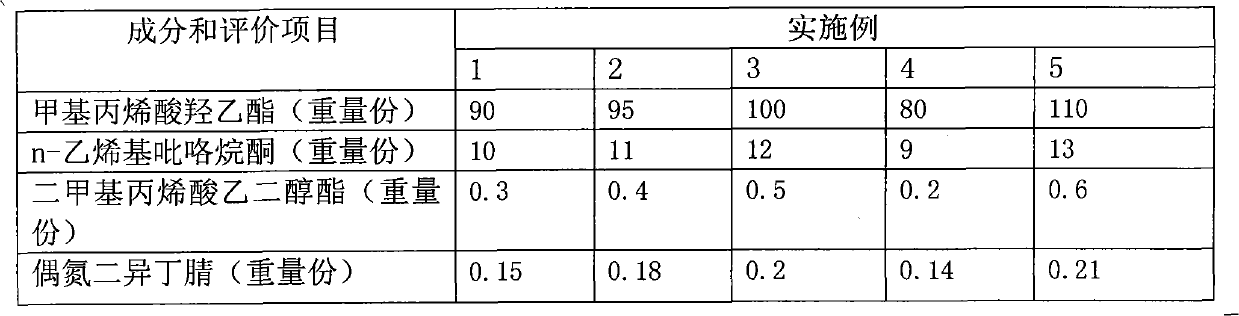

[0103] Embodiment 2-5 carries out the same operation as embodiment 1 except that the proportioning ratio of components is changed, and the results are shown in Table 1.

[0104] Table 1

[0105]

[0106]

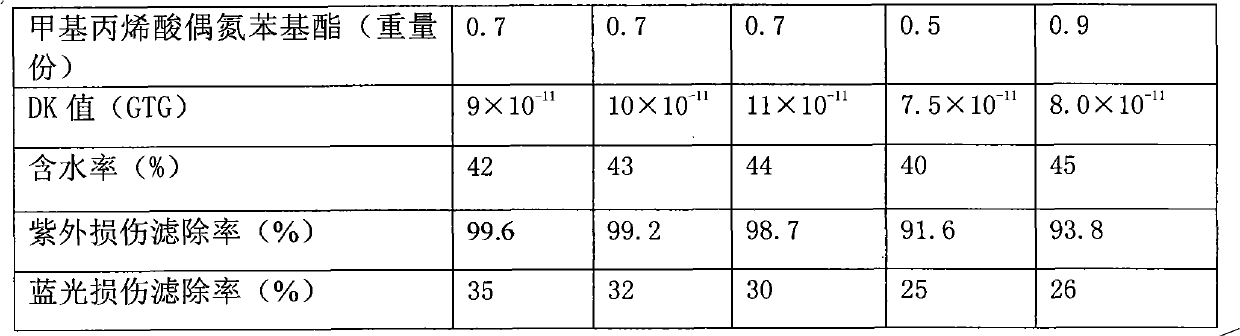

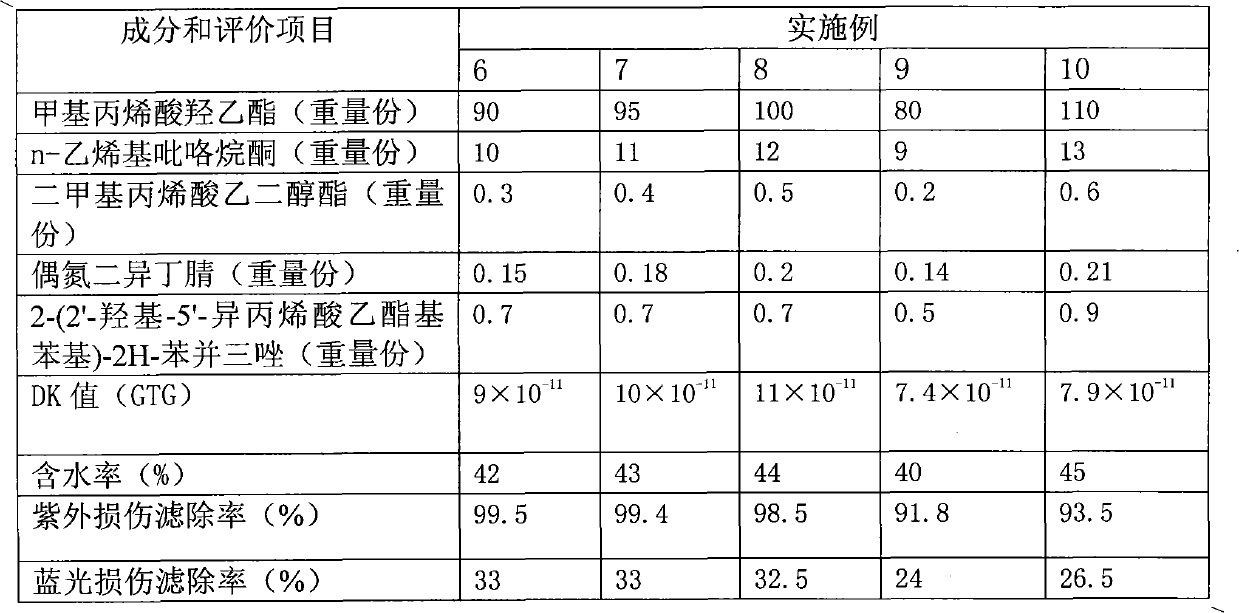

Embodiment 6-10

[0108] Embodiment 6-10 carries out the same operation with embodiment 1 except that the proportioning ratio of components is changed, and the difference between embodiment 6-10 and embodiment 1-5 is to use 2-(2'-hydroxyl-5' -ethyl (isoacrylate) phenyl)-2H-benzotriazole instead of azophenyl methacrylate, the results are shown in Table 2.

[0109] Table 2

[0110]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com