A Directional Coupler Based on Transformer

A directional coupler and transformer technology, applied in waveguide-type devices, circuits, connecting devices, etc., can solve the problems of directional couplers with small insertion loss area, the length can not meet the requirements of integration, and improve the complexity of the system, and achieve the scope of application. Wide, low cost, good directional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below through the embodiments and in conjunction with the accompanying drawings.

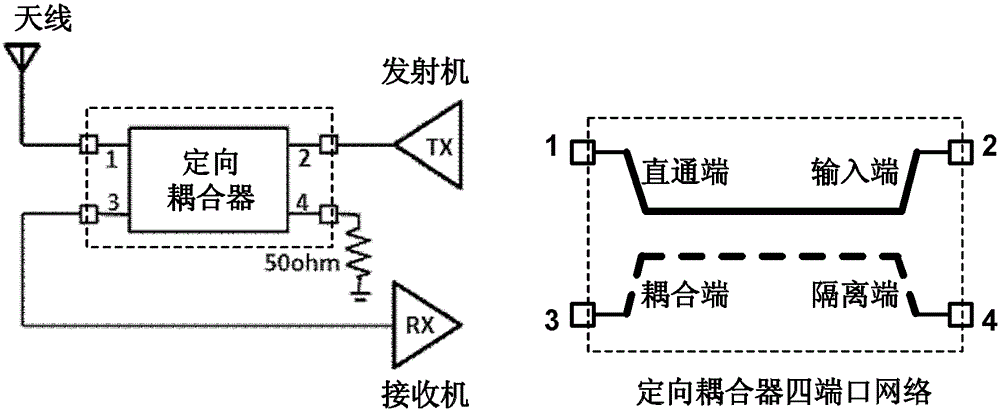

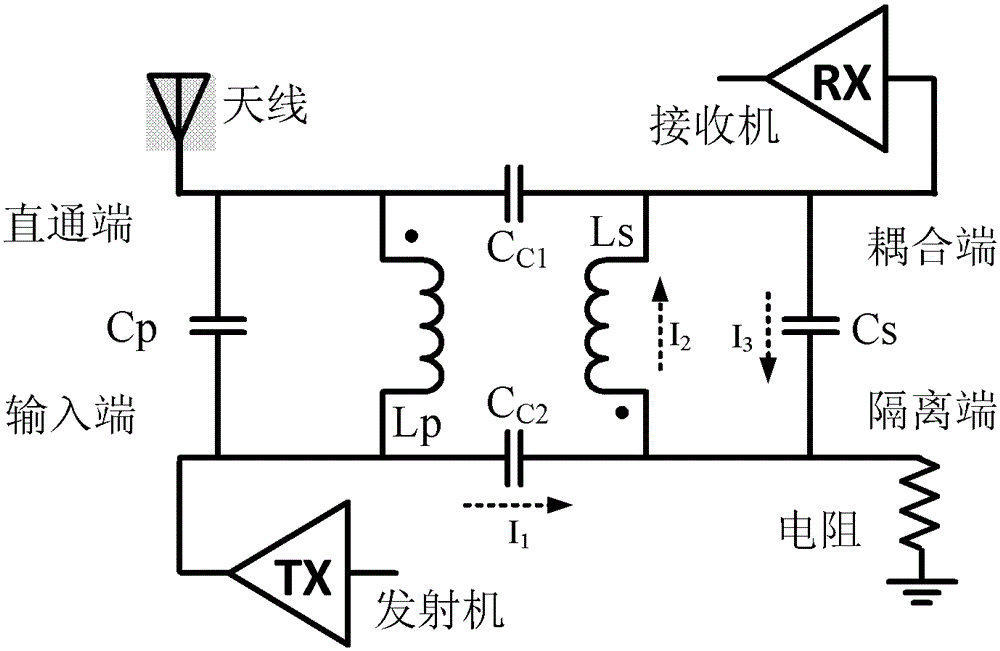

[0038] The transformer-based directional coupler of this embodiment is implemented on a standard CMOS process or a BiCMOS process, image 3 is the schematic diagram of the directional coupler. As shown in the figure, the directional coupler includes two coupled coils Lp and Ls, the two ends of the coil Lp are respectively used as the input end and the through end, and the two ends of the coil Ls are respectively used as the coupling end and the isolation end. An adjustable capacitor array Cp is provided between the input terminal and the through terminal for frequency tuning; an adjustable capacitor array Cs is provided between the coupling terminal and the isolation terminal for isolation tuning. Cp and Cs can make the directional coupler obtain the best performance under the application conditions of different input impedance or process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com