Precursor carbonization plasma cladding reaction synthesized WC reinforced metal based alloy coating and preparation

A technology of plasma cladding and alloy coating, applied in the field of material surface strengthening, can solve the problems of insignificant enhancement of coating performance, limiting the application and development of WC reinforced metal-based alloy coating, etc. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

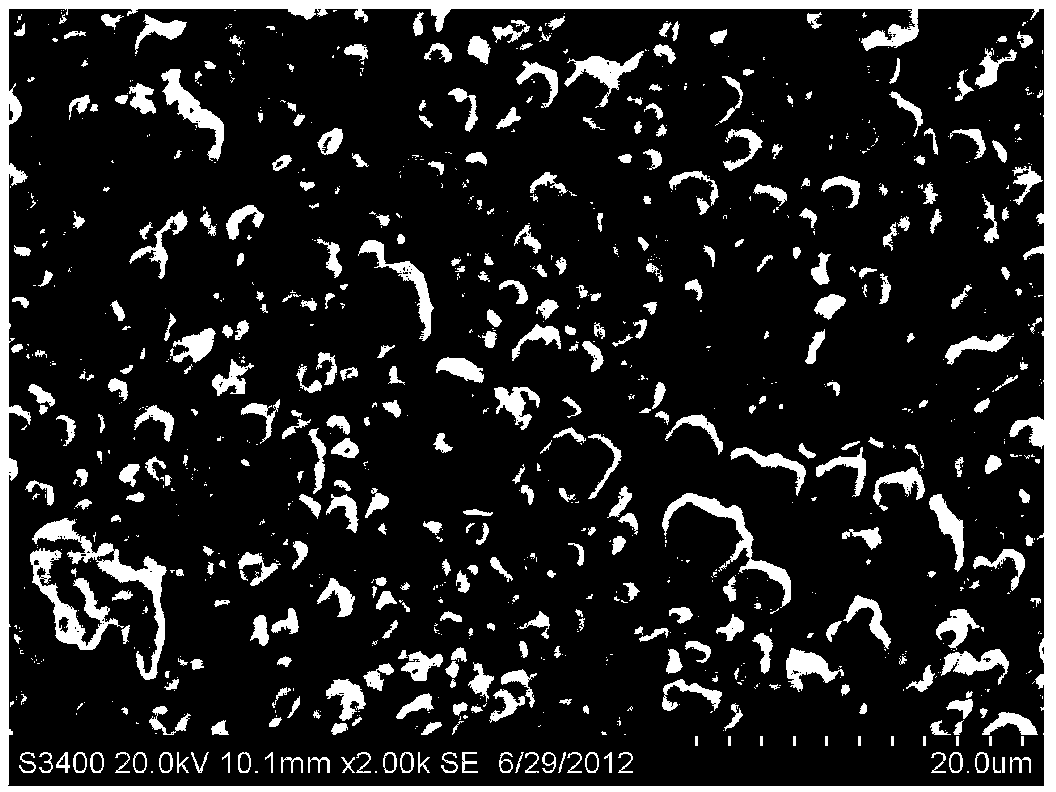

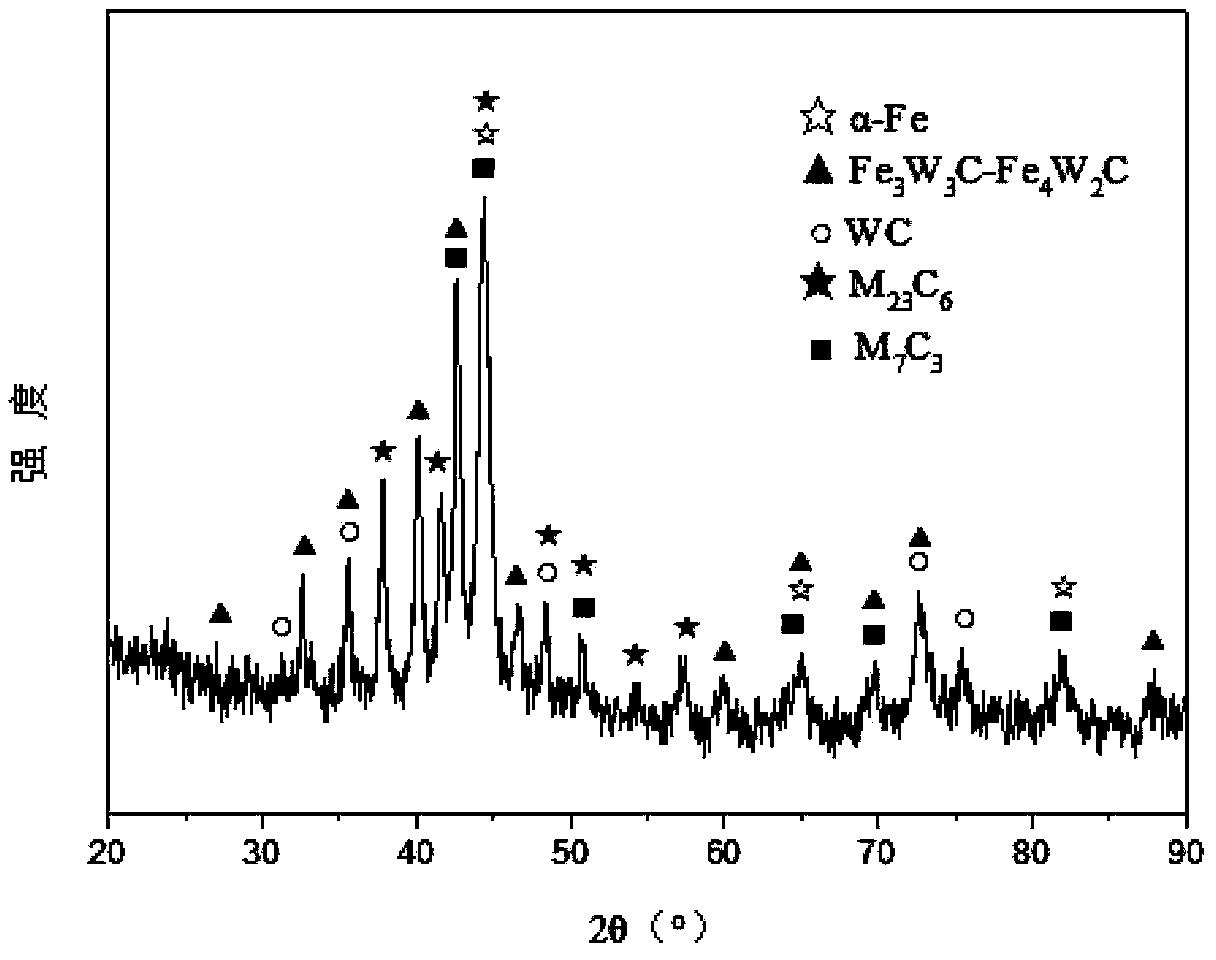

[0024] A WC reinforced metal-based alloy coating synthesized by precursor carbonization plasma cladding reaction, characterized in that the composition of each element in the mixed powder for synthesizing the coating is calculated by mass percentage: W is 28%, C is 2%, Cr is 9%, B is 1%, Si is 0.8%, Mo is 0.5%, and the rest is Fe; the thickness of this coating is 3.5mm, and the width of single-pass cladding layer is 7mm; this coating includes iron-based solid solution, WC, (Fe ,Cr,W) 7 C 3 、(Fe,Cr,W) 23 C 6 and Fe 3 W 3 C-Fe 4 W 2 C, coating section hardness 1300HV 0.1 , surface hardness 69HRC.

Embodiment 2

[0026] A WC reinforced metal-based alloy coating synthesized by precursor carbonization plasma cladding reaction, characterized in that, the composition of each element in the mixed powder for synthesizing the coating is calculated by mass percentage: W is 18.8%, C is 1.2%, Cr 10% for B, 1.2% for B, 1% for Si, 0.6% for Mo, and Fe for the rest; the thickness of this coating is 4.5mm, and the width of a single cladding layer is 10mm; this coating includes iron-based solid solution, WC, (Fe ,Cr,W) 7 C 3 、(Fe,Cr,W) 23 C 6 and Fe 3 W 3 C-Fe 4 W 2 C, coating section hardness 1200HV 0.1 , surface hardness 67HRC.

Embodiment 3

[0028] A WC reinforced metal-based alloy coating synthesized by precursor carbonization plasma cladding reaction, characterized in that the composition of each element in the mixed powder for synthesizing the coating is calculated by mass percentage: W is 10%, C is 1%, Cr B is 12%, B is 1.5%, Si is 1.1%, Mo is 0.8%, and the rest is Fe; the thickness of this coating is 4mm, and the width of single cladding layer is 9mm; this coating includes iron-based solid solution, WC, (Fe, Cr, W) 7 C 3 、(Fe,Cr,W) 23 C 6 and Fe 3 W 3 C-Fe 4 W 2 C, coating section hardness 1000HV 0.1 , surface hardness 64HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com