Ultrasonic flow rate detection system

A technology of flow detection and ultrasonic, which is applied in the field of ultrasonic flow detection system, can solve the problems of high measurement accuracy, easy intrusion of interference signals, and influence of measurement accuracy, etc., to improve resolution, shorten operation cycle, and reduce related operation amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

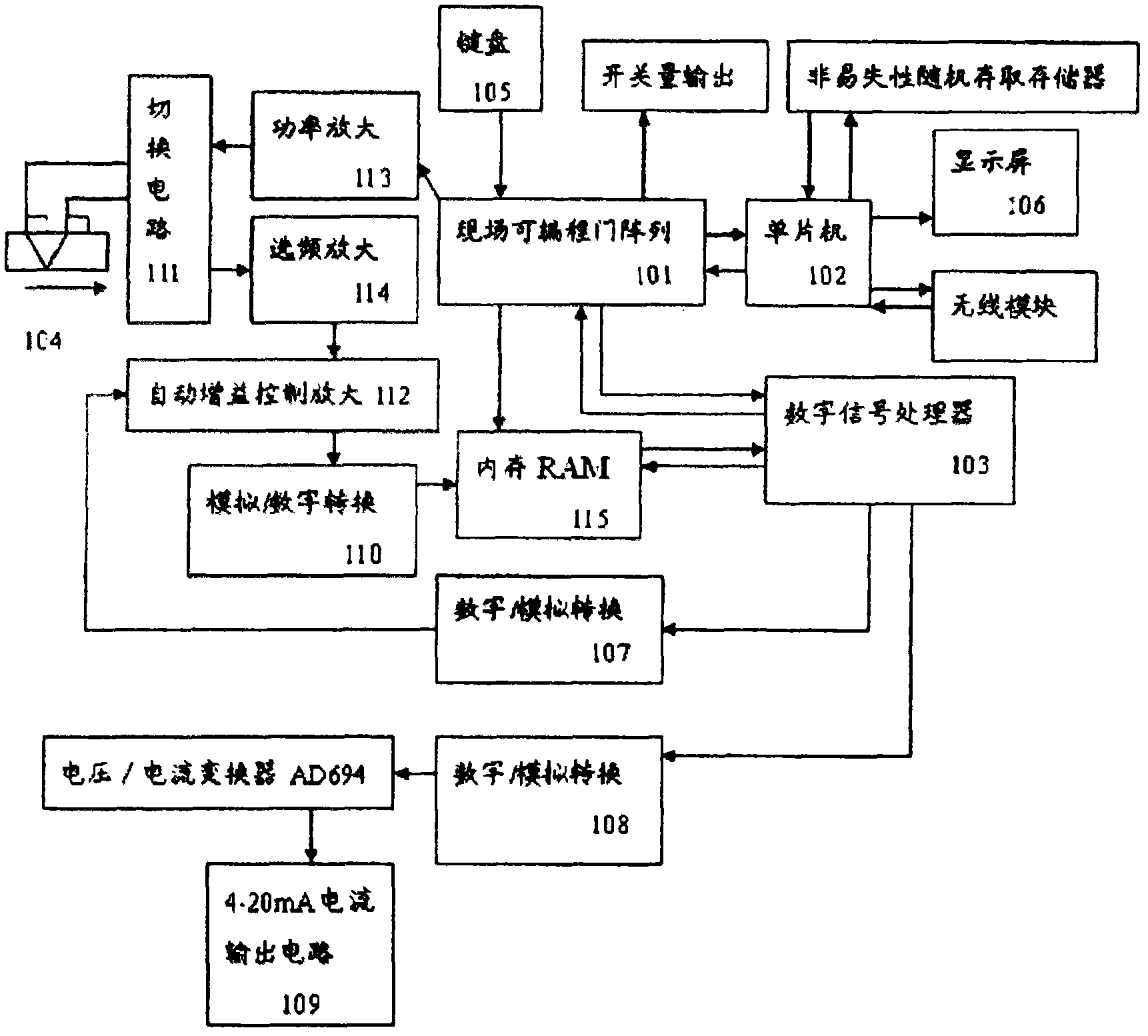

[0008] An ultrasonic flow detection system, including a system control unit, a circuit unit and an auxiliary device; the system control unit further includes: a single-chip microcomputer 102 for system control, data access and communication; for signal filtering and related calculations A digital signal processor 103; a field programmable gate array 101 for timing control and level conversion; the circuit part further includes: a switching circuit 111, an automatic gain control amplifying circuit 112, an analog / digital conversion circuit 110, a digital / Analog conversion circuits 107, 108; the auxiliary device further includes: a storage unit, an input device 105, a display device 106, a power supply and an ultrasonic transducer 104; wherein, the field programmable gate array 101 is connected to the input device 105 respectively It is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com