Composite curing agent for city sludge solidification/stabilization and application thereof

A composite curing agent and municipal sludge technology, applied in the field of municipal and environmental engineering, can solve the problems of poor stabilization of heavy metals and toxic organics, landfill sanitation, secondary pollution of odor, soil alkalization, etc. Improve microbial structure characteristics, good curing and stabilization effect, speed up dehydration and reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

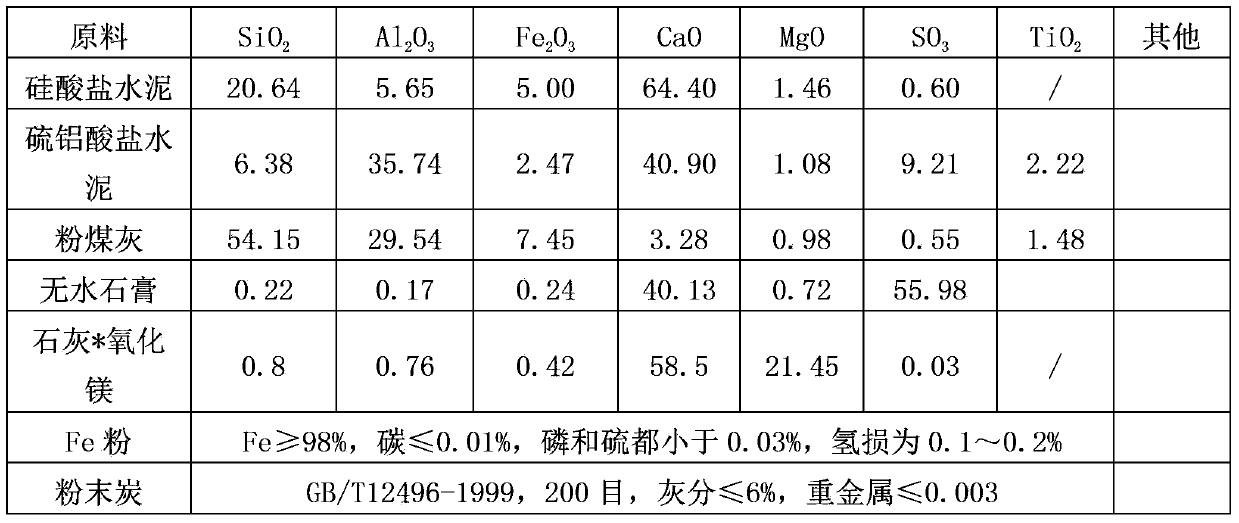

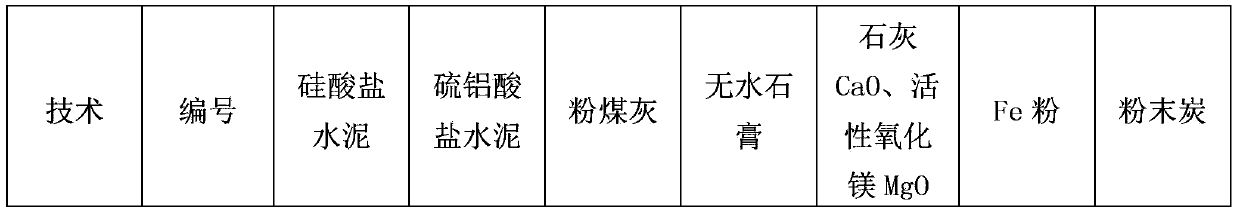

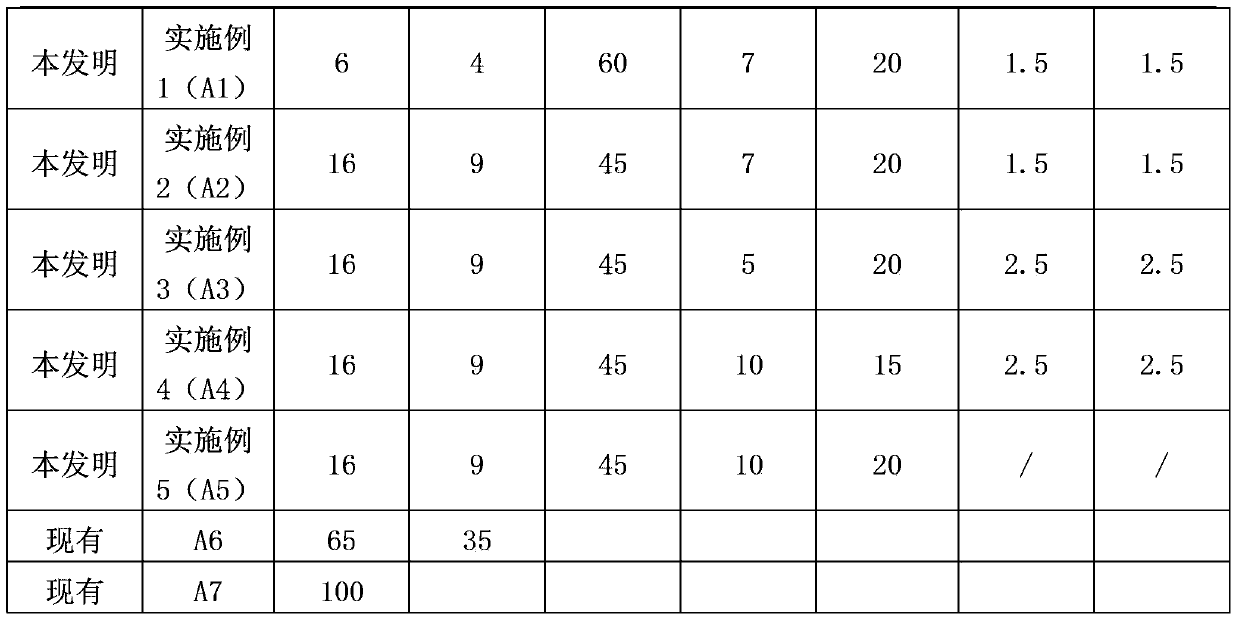

[0024] A composite curing agent for solidification / stabilization of municipal sludge, which is composed of cement, fly ash, anhydrite, lime, activated magnesia, iron powder, powdered activated carbon (powdered carbon), and the chemical composition of the raw materials used See Table 1; See Table 2 for the mass percentage of each raw material.

[0025] The preparation method of the composite solidifying agent of above-mentioned a kind of urban sludge solidification / stabilization, it comprises the steps:

[0026] 1) Select the above raw materials and set aside;

[0027] 2) Mix cement, fly ash, anhydrite, lime, activated magnesia, iron powder and powdered activated carbon (powder carbon) to obtain a composite curing agent for solidifying / stabilizing municipal sludge.

[0028] The application of the composite solidifying agent of above-mentioned a kind of municipal sludge solidification / stabilization, it comprises the steps: the composite solidifying agent of municipal sludge sol...

Embodiment 6

[0044] A composite curing agent for solidification / stabilization of municipal sludge, which is composed of cement, fly ash, anhydrite, lime, activated magnesia, iron powder, powdered activated carbon (powdered carbon), and the chemical composition of the raw materials used See Table 1;

[0045] The mass percentage of each raw material is: cement 22%, fly ash 60%, anhydrite 6%, lime CaO and activated magnesium oxide MgO 10%, iron powder 1%, powdered activated carbon 1%. Among them, the mass ratio of lime CaO and active magnesium oxide MgO is 2:1.

[0046] The preparation method of the composite solidifying agent of above-mentioned a kind of urban sludge solidification / stabilization, it comprises the steps:

[0047] 1) Select the above raw materials and set aside;

[0048] 2) Mix cement, fly ash, anhydrous gypsum, lime, activated magnesia, iron powder and powdered carbon to obtain a composite curing agent for solidifying / stabilizing municipal sludge.

[0049] The application ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com