Fiber- reinforced polyphenylene sulfide/polyamide alloy material and preparation method thereof

A polyphenylene sulfide and fiber-reinforced technology, which is applied in the field of fiber-reinforced polyphenylene sulfide/polyamide alloy materials and its preparation, can solve the problems of material performance degradation, unusable antistatic agents, and lack of antistatic properties. problems, achieve excellent mechanical properties, reduce production costs, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

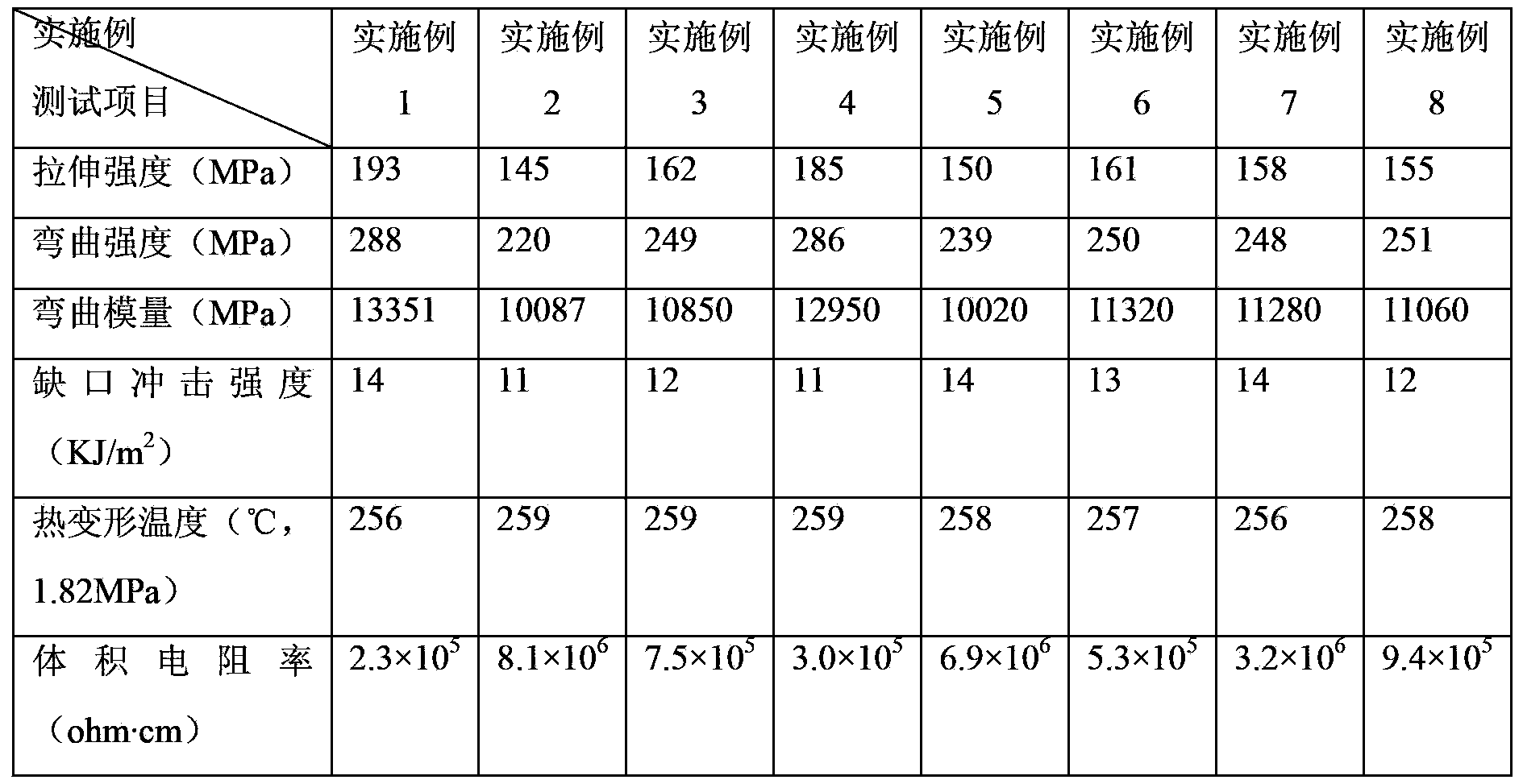

Examples

Embodiment 1

[0033] (1) Weigh 25 parts of PA66, 25 parts of PPS, 25 parts of chopped polyacrylonitrile-based carbon fiber, 25 parts of chopped glass fiber, 0.5 part of antioxidant ST3615, 0.7 part of lubricant PETs, 0.5 part of lubricant GM-100, 0.7 parts of coupling agent KH590, 0.8 parts of coupling agent TTS;

[0034] (2) Mix the above weighed PA66, PPS, ST3615, PETs, GM-100, KH590 and TTS evenly;

[0035] (3) Then, enter the twin-screw extruder, add 25 parts of chopped polyacrylonitrile-based carbon fiber and 25 parts of glass fiber at the side feeding port of the extruder, the temperature of the first zone is 220~250℃, and the temperature of the second zone is 260~ 280°C, the temperature of the third zone is 270~280°C, the temperature of the fourth zone is 280~290°C, the temperature of the fifth zone is 280~290°C, the temperature of the sixth zone is 280~290°C, the temperature of the die is 270~280°C, extrusion cooling, drying, Diced;

[0036] (4) Dry the obtained particles at 100°C...

Embodiment 2

[0038] (1) Weigh and dry 56 parts of PPS, 14 parts of PA, 15 parts of chopped pitch-based carbon fiber, 15 parts of chopped glass fiber, 0.7 part of antioxidant ST3611, 0.7 part of lubricant PETs, 0.5 part of KH590 and 0.5 part of TTS;

[0039] (2) Mix the above weighed PA66, PPS, ST3611, PETs, KH590 and TTS evenly;

[0040] (3) Then enter the twin-screw extruder, add 15 parts of chopped glass fiber and 15 parts of chopped pitch-based carbon fiber at the side feeding port of the extruder, the temperature of the first zone is 220~250℃, and the temperature of the second zone is 260~280 ℃, the temperature in the third zone is 270~280℃, the temperature in the fourth zone is 280~290℃, the temperature in the fifth zone is 280~290℃, the temperature in the sixth zone is 280~290℃, the temperature of the head is 270~280℃, extrusion cooling, drying, cutting grain;

[0041] (4) The obtained particles are dried at 100°C for 6 hours, and injection molded. The temperature of the injection ...

Embodiment 3

[0043] (1) Weigh and dry 42 parts of PPS, 18 parts of PA66, 20 parts of chopped polyacrylonitrile-based carbon fiber, 20 parts of chopped glass fiber, 0.6 part of antioxidant 412s, 0.7 part of lubricant PETs, 0.3 part of lubricant GM-100, 0.6 parts of KH590 and 0.6 parts of TTS;

[0044] (2) Mix the above weighed PA66, PPS, 412s, PETs, GM-100, KH590 and TTS evenly;

[0045] (3) Then enter the twin-screw extruder, add 20 parts of chopped polyacrylonitrile-based carbon fiber and 20 parts of chopped glass fiber at the side feeding port of the extruder, the temperature of the first zone is 220~250 ℃, and the temperature of the second zone is 260 ~280℃, the temperature of the third zone is 270~280℃, the temperature of the fourth zone is 280~290℃, the temperature of the fifth zone is 280~290℃, the temperature of the sixth zone is 280~290℃, the temperature of the die is 270~280℃, extrusion cooling and drying , diced;

[0046] (4) Dry the obtained particles at 100°C for 5 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com