A preparation method for a membrane electrode used for a microbattery, the membrane electrode and the microbattery

A thin-film electrode and micro-battery technology, applied in the field of micro-battery, can solve problems such as inability to achieve micro-battery, and achieve the effects of reliable performance, good controllability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention discloses a method for preparing a thin-film electrode for a micro-battery, wherein the operation steps include:

[0034] a), configure an electrolytic solution composed of 90-99wt% non-aqueous polar alcohol and 1-10wt% fluoride;

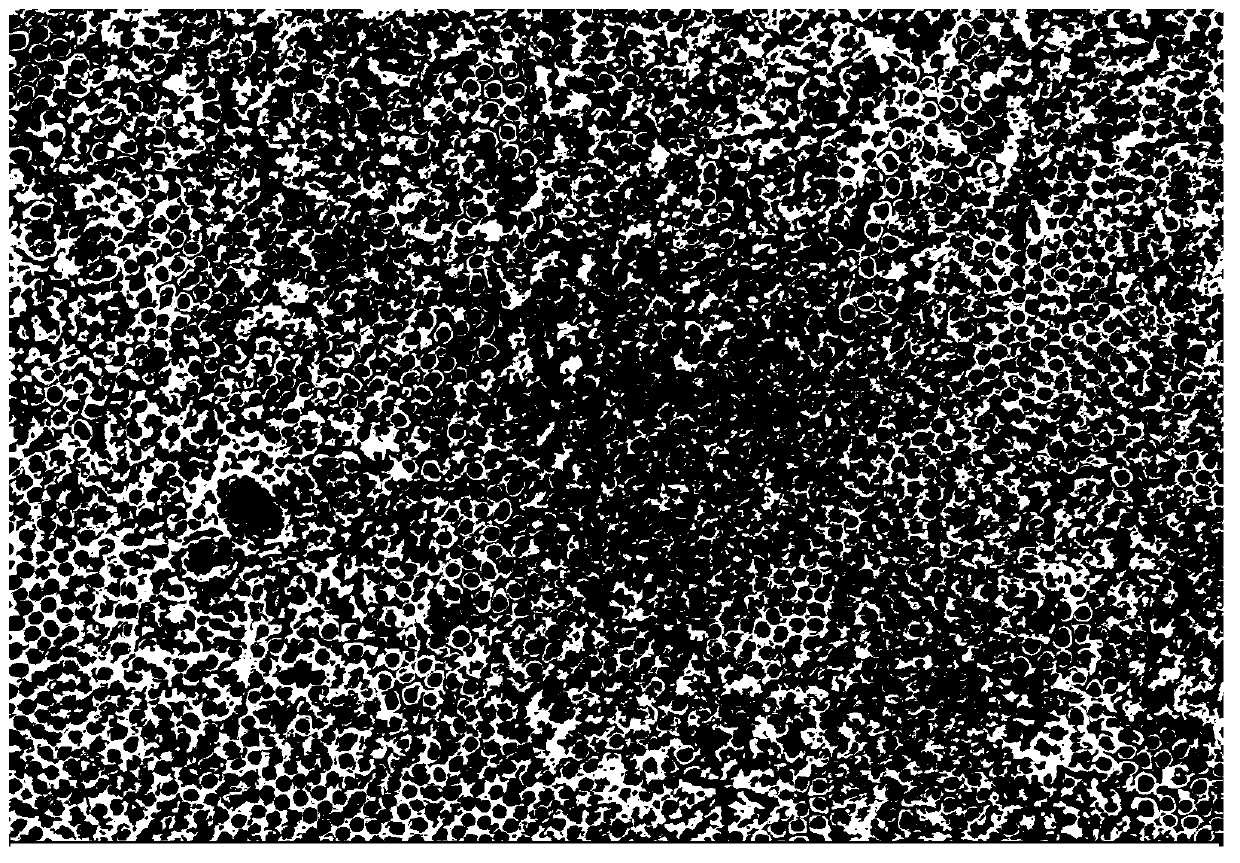

[0035] b) Place the titanium sheet as an anode in the electrolytic solution obtained in the above step a), and perform electrolysis under the action of a periodic voltage, and obtain initial TiO with a micro-nanotube structure on the titanium sheet 2 film;

[0036] c), the initial TiO obtained in the above step b) 2 The film is heated at a temperature of 300-600°C for 1-48 hours;

[0037] d) Obtain TiO with micro-nanotube structure 2 thin film, the TiO 2 Thin films are used as thin-film electrodes for micro-batteries;

[0038] Wherein, the periodic voltage includes: performing a voltage action at a first voltage of 5-100V for 1-300min, and then performing a voltage action at a second voltage of -10...

Embodiment 1

[0053] a) Configure an electrolytic solution composed of 96wt% glycerin + 3wt% sodium fluoride + 1wt% water;

[0054] b) The titanium sheet is used as the anode and the platinum sheet is used as the cathode, respectively placed in the electrolytic solution obtained in the above step a), and the electrolysis is carried out under the action of the periodic voltage, wherein the periodic voltage is: 300min at the first voltage of 10V The voltage is applied, and the number of cycles is 1; then it is washed several times with distilled water, and the initial TiO with micro-nanotube structure is obtained on the titanium sheet. 2 film;

[0055] c), the initial TiO obtained in the above step b) 2 The film is heated at 300°C for 48 hours;

[0056] d) Obtain TiO with micro-nanotube structure 2 thin film, TiO 2 The thin film serves as a thin film electrode for a microbattery.

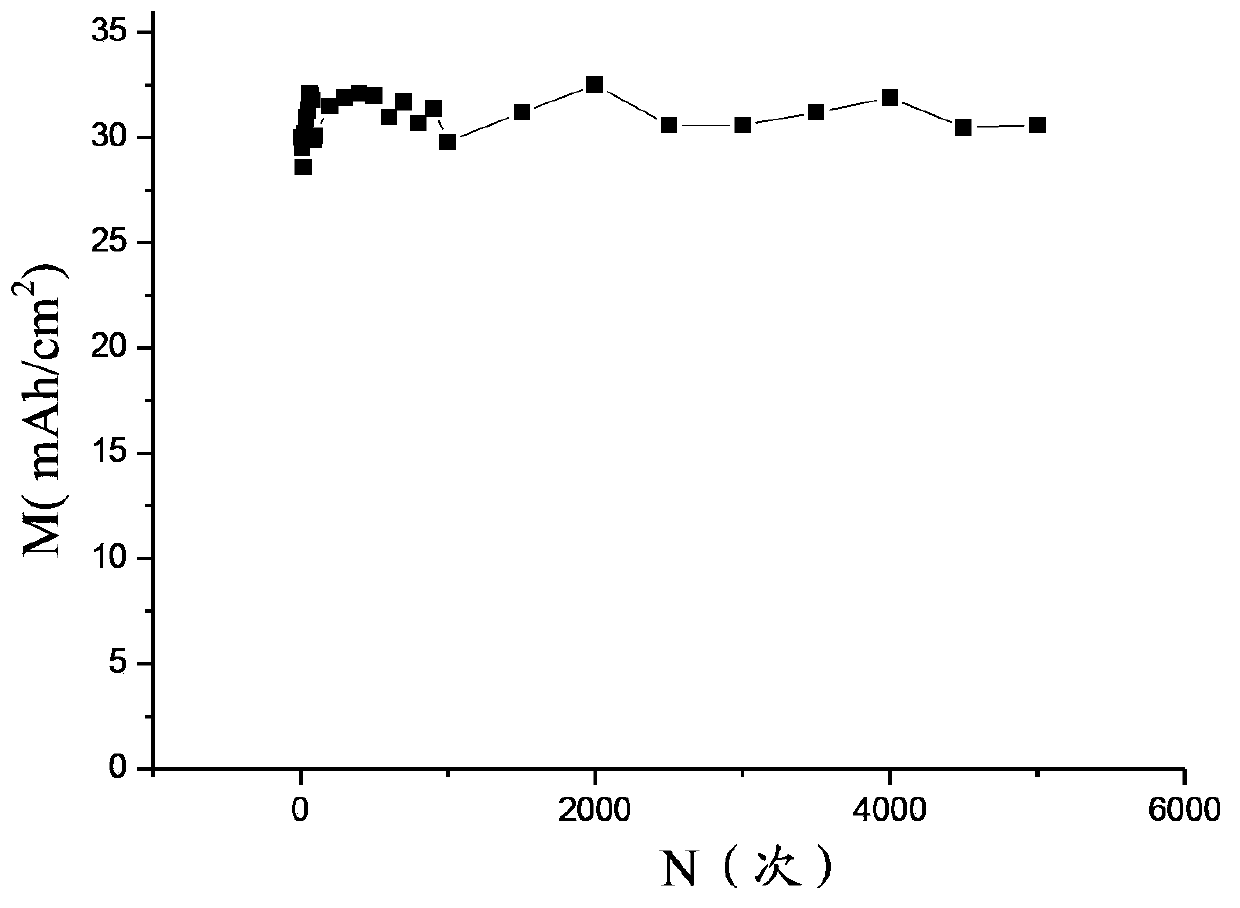

[0057] The above-mentioned present embodiment obtains TiO 2 The thin-film electrode is used as the thin-fi...

Embodiment 2

[0059] a) Configure an electrolytic solution composed of 96wt% ethanol + 3wt% sodium fluoride + 1wt% water;

[0060] b) The titanium sheet is used as the anode and the platinum sheet is used as the cathode, respectively placed in the electrolytic solution obtained in the above step a), and the electrolysis is carried out under the action of the periodic voltage, wherein the periodic voltage is: 2min at the first voltage of 30V The voltage is applied, and then the voltage is applied at the second voltage of 10V for 2min, and the number of cycles is 60 times; then it is washed several times with distilled water, and the initial TiO with micro-nanotube structure is obtained on the titanium sheet. 2 film;

[0061] c), the initial TiO obtained in the above step b) 2 The film is heated at a temperature of 600°C for 1 hour;

[0062] d) Obtain TiO with micro-nanotube structure 2 thin film, TiO 2 The thin film serves as a thin film electrode for a microbattery.

[0063] The above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area specific capacity | aaaaa | aaaaa |

| Area specific capacity | aaaaa | aaaaa |

| Area specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com