Preparation method of ginseng lactic acid fermentation beverage

A technology of lactic acid fermentation and ginseng, which is applied in the field of preparation of ginseng lactic acid fermented beverages, can solve the problems of unfavorable fermentation, ginseng without fermented beverages, and the quality of fermented beverages cannot be achieved, and achieve high nutritional value, sour and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

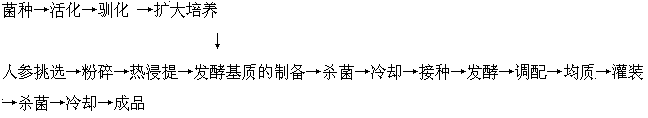

[0021] The process flow and parameters are as follows:

[0022] process such as figure 1 as shown,

[0023] 1. Raw materials and auxiliary materials: fresh ginseng, white sugar, stabilizer, skimmed milk powder.

[0024] 2. Pretreatment: When the raw material is 500 grams of fresh ginseng, cut into 3-5mm slices, add water 8 times the weight of ginseng and heat to 80°C for beating to obtain ginseng extraction slurry.

[0025] 3. Domestication of strains: adopt the method of gradually increasing the concentration of ginseng extract in the culture medium, and carry out mixed gradient domestication of lactic acid bacteria. In order to make lactic acid bacteria better adapt to the growth environment of ginseng extract and obtain the largest amount of lactic acid bacteria, screening out the best strains.

[0026] Preparation of starter: select symbiotic Streptococcus thermophilus (St) and Lactobacillus bulgaricus (Lb), respectively activate, domesticate, and expand the culture to ...

Embodiment 2

[0035] process such as figure 1 as shown,

[0036] 1. Raw material preparation: Select 500 grams of high-quality raw sun-dried ginseng, and crush it to particles below 1mm by a tissue grinder.

[0037] 2. Extraction: Extract raw sun-dried ginseng: water at a ratio of 1:30, temperature 80°C, time 100 min, filter and dilute the extract to 30 times the mass of raw sun-dried ginseng.

[0038] 3. Domestication of strains: adopt the method of gradually increasing the concentration of ginseng extract in the culture medium, and carry out mixed gradient domestication of lactic acid bacteria. In order to make lactic acid bacteria better adapt to the growth environment of ginseng extract and obtain the largest amount of lactic acid bacteria, screening out the best strains. Preparation of starter: select symbiotic Streptococcus thermophilus (St) and Lactobacillus bulgaricus (Lb), respectively activate, domesticate, and expand the culture to obtain a bacterial count of 10 8 / mL or more,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com