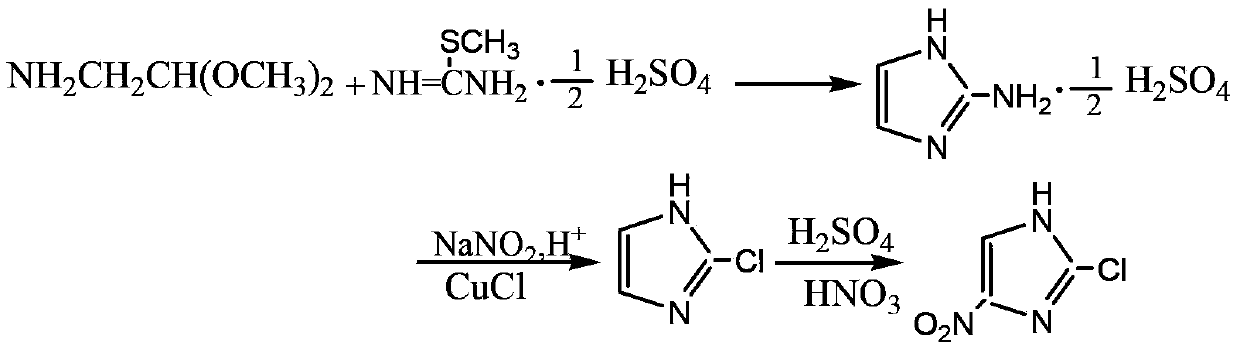

A kind of method for preparing 2-chloro-4-nitroimidazole

A technology of nitroimidazole and clomidazole, which is applied in the direction of organic chemistry, can solve the problems of easy explosion accidents, many by-products, and difficult industrialization, and achieve the effects of easy industrial production, high product quality, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 9.94g of aminoacetaldehyde diethyl acetal (0.074mol), 20.6g of S-methylisothiourea sulfate (0.074mol) and 16.5ml of water into the three-necked flask successively, then raise the temperature to 110°C, and stir the reaction for 1.5h. Stop responding. Evaporate the solvent, then add 13.0g of 37% hydrochloric acid (mass percent concentration, the same as in the following examples) to the reaction solution, stir at 65°C for 1 hour, add 50ml of water, evaporate the solvent, add 30ml of acetone, and precipitate light yellow crystals. After filtration, the crude product was recrystallized with 30ml of ethanol-water to obtain 15.90g of off-white powdery solid 2-aminoimidazole sulfate, yield 81.5%, mp271.2~273.0℃.

[0022] Add 15g of 37% hydrochloric acid and 10.56g of 2-aminoimidazole sulfate (0.04mol) into a three-necked flask, and dropwise add 10.8g of 25.9% sodium nitrite solution (mass percentage concentration, the same as the following examples) (0.04mol) under ice-wat...

Embodiment 2

[0025] Add 7.8g of aminoacetaldehyde dimethyl acetal (0.074mmol), 20.6g of S-methylisothiouronium sulfate (0.074mmol) and 16.5ml of water into the three-necked flask successively, then raise the temperature to 110°C, and stir for 1.5h. Stop responding. Evaporate the solvent, then add 13.0g of 37% hydrochloric acid (mass percent concentration, the same as in the following examples) to the reaction solution, stir at 65°C for 1 hour, add 50ml of water, evaporate the solvent, add 30ml of acetone, and precipitate light yellow crystals. After filtration, the crude product was recrystallized with 30ml of ethanol-water to obtain 15.31g of off-white powdery solid 2-aminoimidazole sulfate, yield 78.5%, mp271.2~273.0℃.

[0026] Add 15g37% hydrochloric acid and 3.3g2-aminoimidazole (0.04mol) into the three-necked flask, add dropwise 10.8g25.9% sodium nitrite solution (mass percentage concentration, the same as the following examples) (0.04mol) under ice-water bath, maintain The reaction ...

Embodiment 3

[0029] With the method of embodiment 1, the difference is that the reaction molar ratio of aminoacetaldehyde diethyl acetal and S-methylisothiouronium sulfate is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com