Plugging agent and preparation method thereof

A technology of plugging agent and initiator, which is applied in the field of drilling and can solve the problem of small return volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

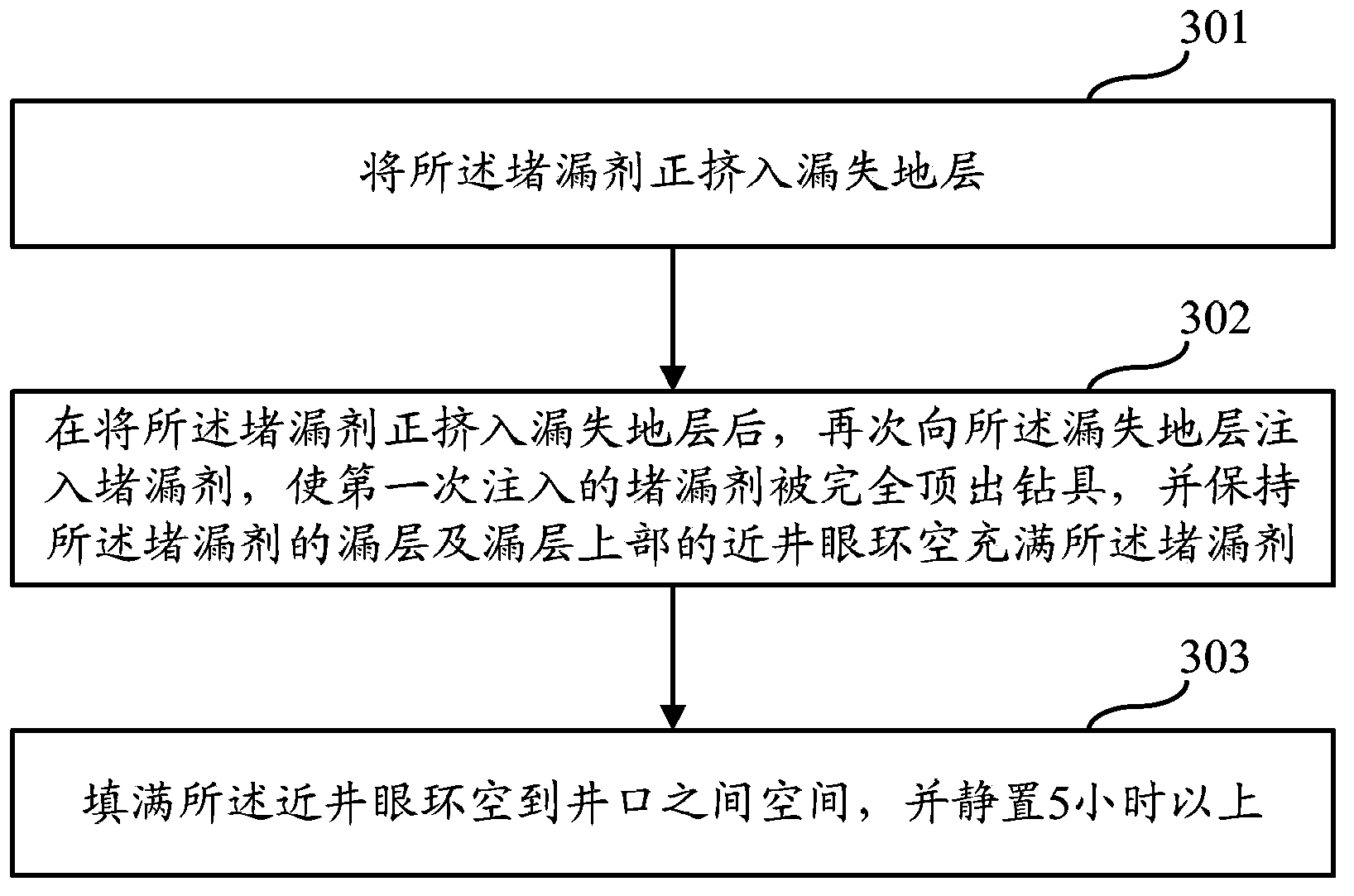

Method used

Image

Examples

preparation example Construction

[0130] In order to prepare the above-mentioned plugging agent, Embodiment 1 of the present invention also provides a preparation method (hydrolysis method after copolymerization) of the plugging agent, which includes the following steps:

[0131] 1) Hydrolysis method after copolymerization

[0132] Add deionized water according to the metering ratio, add the raw materials into it and stir evenly to form a monomer solution; then pass high-purity nitrogen into the monomer solution, and use frozen brine or thermal circulating water bath to control the temperature of the system (ie, the polymerization temperature); Then add an initiator to the monomer solution to initiate polymerization; after the polymerization reaction, crush the water-soluble hydrophobic association polymer colloid into particles, add sodium hydroxide or sodium carbonate to hydrolyze, dry and pulverize to obtain the product.

[0133] Wherein, the comonomers include amphiphilic unsaturated monomers, hydrophobic ...

Embodiment 2

[0146] If the water-soluble hydrophobic association polymer monomer adopts any one or more of amphiphilic unsaturated monomers, hydrophobic ethylenically unsaturated monomers and nonionic ethylenically unsaturated monomers. Then its preparation method can also be copolymerization co-hydrolysis method, comprises the following steps:

[0147] Add deionized water according to the metering ratio, add raw materials into it and stir to form a monomer solution; then add a certain quality of sodium hydroxide or sodium carbonate, stir evenly; then pass high-purity nitrogen into the monomer solution, and use freezing The temperature of the system is controlled by salt water or a thermal circulating water bath (that is, the polymerization temperature); then an initiator is added to the monomer solution to initiate polymerization; after the polymerization reaction is completed, the water-soluble hydrophobic association polymer colloid is crushed into particles, and dried and crushed Get i...

example 1

[0175] Recipe: 1.2 parts of polymer + 98.8 parts of H 2 O, viscosity 35800mPa.s, static shear force 19.0Pa; applicable conditions: shallow well, low temperature (within 70°C), pressure (difference) less than 3MPa.

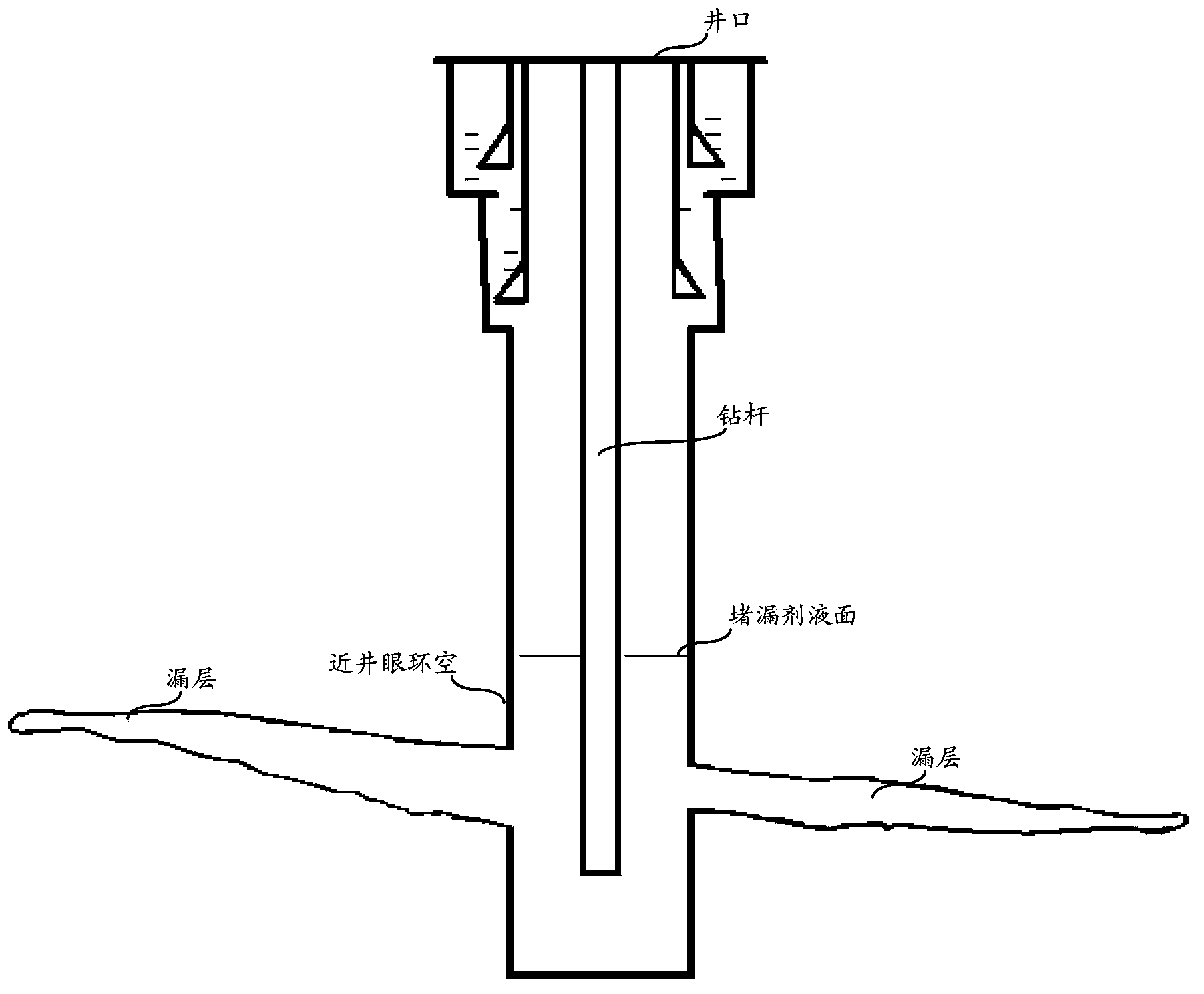

[0176] Field Application

[0177] When the leakage occurred at 1629 meters in Well Liu 67-72, the mud density used was 1.02-1.03g / cm 3 , The maximum leakage liquid level is 200 meters, and the particle size of the bridging material is 3-5mm, and the cement plugging failed nine times. The liquid level was detected to be 29 meters, the drill pipe was drilled down to 1500 meters, and the plugging agent of the present invention was pumped in for 34 meters. 3 , and then inject 12m of clean water 3 , Pulled out the drilling tool and let it stand for 6 hours, then went down to the bottom of the well, and the flowback volume was normal when the pump was turned on. After 15 minutes of circulation, 150KN+65rpm drilled 8 meters, the pump pressure and displacement were all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com