Bio-based methanol gasoline hydrotropy cold initiator and preparation method thereof

A methanol gasoline, bio-based technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as low-temperature cold-start difficulties, corrosion swelling, water stratification, etc., to achieve extensive promotion value and less addition , significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

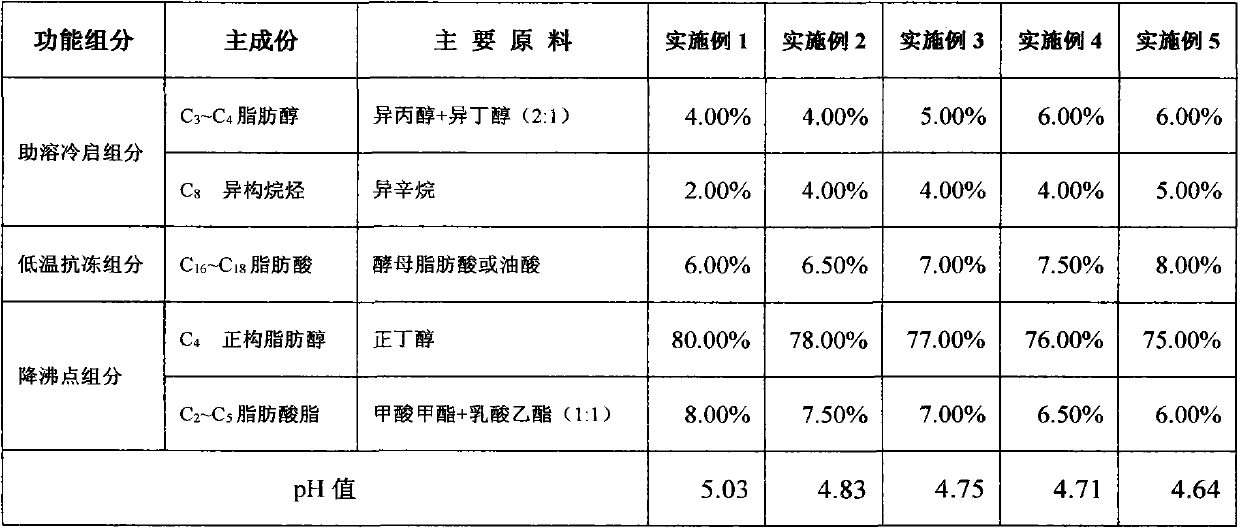

Embodiment 1

[0026] A bio-based methanol gasoline solubilizing cold-starting agent is composed of the following functional components in volume percentage:

[0027] Solubilizing cold start component: C 3 ~C 4 Fatty Alcohol 4.0%

[0028] C 8 Isoparaffin 2.0%

[0029] Low temperature antifreeze component: C 16 ~C 18 Fatty Acid 6.0%

[0030] Boiling point components: C 4 Fatty Alcohol 80.0%

[0031] C 2 ~C 5 Fat Fat 8.0%

[0032] Among them: C of the cold start component of the solubilization 3 ~C 4 Fatty alcohol is composed of isomeric middle-carbon alcohols, preferably isopropanol, or a mixture of isopropanol and isobutanol in a volume ratio of 2:1, C 8 Isoparaffin is isooctane; C of low temperature antifreeze component 16 ~C 18 The fatty acid is a yeast fatty acid; the C of the boiling point reduction component 4 The fatty alcohol is n-butanol, C 2 ~C 5 One or both of methyl formate and ethyl lactate in equal proportions by volume. Add the sol...

Embodiment 2

[0034] A bio-based methanol gasoline solubilizing cold-starting agent is composed of the following functional components in volume percentage:

[0035] Solubilizing cold start component: C 3 ~C 4 Fatty Alcohol 4.0%

[0036] C 8 Isoparaffin 4.0%

[0037] Low temperature antifreeze component: C 16 ~C 18 Fatty acids 6.5%

[0038] Boiling point components: C 4 Fatty Alcohol 78.0%

[0039]C 2 ~C 5 Fat Fat 7.5%

[0040] Among them: C of the cold start component of the solubilization 3 ~C 4 Fatty alcohol is composed of isomeric middle-carbon alcohols, preferably isopropanol, or a mixture of isopropanol and isobutanol in a volume ratio of 2:1, C 8 Isoparaffin is isooctane; C of low temperature antifreeze component 16 ~C 18 The fatty acid is a yeast fatty acid; the C of the boiling point reduction component 4 The fatty alcohol is n-butanol, C 2 ~C 5 One or both of methyl formate and ethyl lactate in equal proportions by volume. Add the solubilizing cold...

Embodiment 3

[0042] A bio-based methanol gasoline solubilizing cold-starting agent is composed of the following functional components in volume percentage:

[0043] Solubilizing cold start component: C 3 ~C 4 Fatty Alcohol 5.0%

[0044] C 8 Isoparaffin 4.0%

[0045] Low temperature antifreeze component: C 16 ~C 18 Fatty Acid 7.0%

[0046] Boiling point components: C 4 Fatty Alcohol 77.0%

[0047] C 2 ~C 5 Fat Fat 7.0%

[0048] Among them: C of the cold start component of the solubilization 3 ~C 4 Fatty alcohol is composed of isomeric middle-carbon alcohols, preferably isopropanol, or a mixture of isopropanol and isobutanol in a volume ratio of 2:1, C 8 Isoparaffin is isooctane; C of low temperature antifreeze component 16 ~C 18 The fatty acid is a yeast fatty acid; the C of the boiling point reduction component 4 The fatty alcohol is n-butanol, C 2 ~C 5 One or both of methyl formate and ethyl lactate in equal proportions by volume. Add the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Calorific value of combustion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com